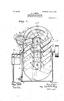

1,427,509. J. C.'ANDERSON. WINDING MACHINE. llllllllliiimiiiiillillllllllllllllllllllllll

|

|

|

- Florence Wilson

- 6 years ago

- Views:

Transcription

1 1,427,509. J. C.'ANDERSON. WINDING MACHINE. APPLICAHON FILED JUNE Patented Aug. 29, SHEETS' SHEET I.. 'l'l'?l llllllllliiimiiiiillillllllllllllllllllllllll l-ll INVENTOR.

2 J. C. ANDERSON. WINDING MACHINE. APPLICAHON FILED JUNE ,427,509 ~ Patented Aug. 29, SHEETS~SHEET 2'.

3 J. C. ANDERSON. WINDING MACHINE. APPLICATION FILED JUNE 18, ,427, SHEETS-SHEET 3. Patented Aug. 29, III v INVENTOR. A TTORYE r.

4

5 GED ' Fifi-27,509 dicated at b. This layer is surrounded by will thus be seen that when the sliding clutch six wrappings of paper 0 upon which the member 23 engages gear 24 it is then out second layer of wire (Z is wound. This layer of engagement with the collar 25 and the is succeeded by another six wrappings of shaft section 10' is driven from shaft 10 at paper 6 and following this are several lay a rate dependent upon the gear ratio of the ers of wire f which are separated by three train 24, 29, 27, 26. wwhen the clutch mem turns or layers of paper 9. Finally the ber 23 is moved in the opposite direction to outer layer of wire it is separated from the engage the collar 25 the shaft section 10 is layer immediately beneath it by six turns driven at the same speed as shaft 10 while of paper 2' and is externally surrounded by the gear train rotates idly. The gear train another six turns of paper j. It is the func is such that when the. shaft section 10 is tion of the present improvement to intro driven therethrough it rotates at higher duce these varying numbers of turns of speed than when driven direct from shaft paper at selected locations in the helix. 10. Clutch member-23 is shifted by the The machine is driven by a belt 1 which movements of rock shaft 20 which carries passes over a'pulley 2 on a shaft 3 mounted a yoke 30 embracing a groove in the clutch in a housing 4. The shaft 3 carries a chuck member in the usual and well known man 5 for the left end of the winding spindle 6, ner. The shaft section 10 carries at its the right hand end of said spindle being outer end a bevel gear 31 which drives a held in a chuck 7 mounted to rotate in a pinion 82 on an upwardly inclined shaft 83, bearing 8 rising from the frame. The right the shaft having on its other extremity av hand chuck 7 is provided with a collar 9 pinion 34, engaging a pinion 35 at the end serving as a friction gear for a purpose of a paper feeding roller 86 comprising one of a train of paper feeding rollers the others which will hereafter appear. 10 is a shaft which is continuously driven through a train of gears 11-, 12 from the shaft 3. Shaft 10 drives cam shaft 18 through pinion and gear 14. Shaft 13 makes one rotation for each layer of wire wound upon the spindle. This shaft carries a worm 15 which engages a worm gear immediately thereunder and not shown, but mounted loosely upon the shaft 16. A jaw clutch on said shaft is adapted to connect the worm gear thereto, the sliding and keyed member of said clutch being indicated by 17. The clutch is nor mally closed during the operation of the machine so that for each rotation of the shaft 13 which corresponds to the formation of one layer of wire on the spindle, the shaft 16 moves a fraction of a turn. On the periphery of the clutch member 17 may be placed at desired locations one or more pro jecting lugs 18 the outer operating faces of which may be of a length corresponding to one or more of the fractional movements of the shaft 16. During the step by step rotation of shaft 16, the lugs 18 come into contact with and force downward the end of a bell crank lever 19 which is attached to a rock shaft 20 mounted upon the main frame in a bearing bracket 21. The shaft 10 extends across the rear of the machine but is in two, parts separated at the point 22. The driving part of shaft 10 carries a sliding clutch member 23 hav ing a clutch face at each end. The left hand face is adapted to engage the gear wheel 2% to drive the same while the right hand face is adapted to engage a collar 25 on the driven section 10' of the shaft. Ad jacent the collar 25 is a pinion 26 fixed upon the driven shaft section 10 which is in mesh with a gear 27 on a shaft 28 which carriesv a pinion 29 in mesh with the gear 24;». It being indicated by 37, 38 and 39. The bevel gear 31 at the end of shaft section 10' is loose but adapted to be connected with the shaft by means of a clutch LJEO at a certain point in the'cycle of operations of the ma chine. lvhen this clutch is thrown in.v the 95 paper feeding rolls begin tot-urn and the paper is drawn or measured from the con tinuous web 411 which proceeds from the roll of paper 42. It will be understood that at a certain point in the rotation of the shaft 13 the clutch 40 is closed through the mecha nism indicated at as and which merely com prises a cam which actuates a rock shaft carrying a clutch shifting yoke 44:. Referring now to Fig. 2 it will be seen that the web of paper a1, passes from the measuring roller 36 then around the roller 37. then around the roller 38 against- which it is?nally pressed or gripped by the roller 39. From the two gripping rolls 3S and 39, the forward edge of the sheet normally ex tends downward to the point 45 at which lo cation a severing knife (not shown) is lo cated.. Vhen the feeding rolls operate, the end of the paper is fed downward until i. the free end occupies a position indicated by the dotted line L16 after which the sheet is severed at the point a5 and the portion cut o?' is conveyed to a position to be injected into the winding on spindle 6. For the purpose of thus transferring the sheet, there is used, as fully explained in the application before mentioned, a transfer frame 47 which is pivoted at 4:8 and carries two gripping rollers 49 and 50 immediately in front of which is a table or lip 51 upon which the forward end of the sheet rests and is guided on its way to the winding. The two grip ping rollers 419 and 50 are driven through a train of gears shown in Fig. 5 from the in y-a Ur

6 memos leather collar 9 _ on the winding spindle clutch which engages the friction wheel 52 at the proper time. The transfer frame 47 is adapted to be swung rearward from the position shown in Fig. 2 by means of the link 53 the end of which rides against the periphery of cam 54 on the cam shaft 13, a spring, not shown,,serving to keep the end of link 53 against the edge of the cam. 10 When the transfer frame 47 is thus swung to the rear, the gripping rolls 49-5O are at the same time separated so that they occupy positions on opposite sides of the dotted line 46 so that when the paper is fed down 15 i-rard it will pass between the two gripping rolls. The gripping rolls thereupon close upon the sheet, and their axes being in an oblique plane cause the upper edge to bend forward so that when the transfer frame is "returned to the position shown in Fig. 2 the upper edge of the sheet will be presented at a tangent to the winding immediately un der the strands of wire which are indicated at 55 as leading from the guide rolls 56 and to the winding spindle. Cam 54 is pro vided with a supplemental peripheral cam 58 and the end of the link 53 is provided with a pivoted dog or pawl 59 the end of which stands in the plane of the cam 58 so 30 that when the latter is presented to the pawl, the link 53 will be controlled by the cam 58 instead of by the cam. 54 which for the time being is out of contact with the end of the link 53. Cam 58 is provided with a step 60 which when presented to the end of pawl 59 allows the latter together with the link 53 to be pulled towards the shaft 13 and thus impart a sudden forward movement to the transfer frame 47 which serves to bring the friction gear 52 into contact with the friction collar 9 on the spindle. lvhile this contact is maintained the rolls 49-5O rotate and feed the paper to the spindle. Cam 54 therefore serves to swing the transfer frame to a position preparatory to the injection of the paper while cam 58 affords another ad ditional forward movement of the frame to bring the gears into contact to actually in ject the paper. Referring now to Fig. 3, the bell crank lever 19 which is pivoted upon the rock shaft 20, has its arm 61 connected with a rod 62 which is provided with a collar 63 and adjacent to which is suitably pivoted upon the frame a small bell crank lever 64. one arm of which is adapted to be engagedby the collar'63 while the other is attached to an upwardly directed thrust rod 65 which reaches to a point immediately under the pawl 59. The extremity of rod 62 is en gaged by a manually operable lever 66 which is pivoted to the frame at 67 and projects forward within reach of the oper ator at the point 68. The lever 66 is nor mally under the in?uence of a spring 69 which tendsv to hold the bell crank arm 19 in contact with the periphery of the clutch member 17. ' The operation of the improvement is as follows: before winding of any set of coils is begun the step by step moving shaft 16 is turned backward by hand to a zero posi tion, from which during the winding opera tion the shaft moves one step forward for each layer of winding. Assuming the lugs on the periphery of clutch member 17, are located respectively at those points where immediately upon the?rst movement of said clutch member one of the lugs will engage and move downward the end of hell crank 19 and will hold the same in this de- pressed.position while two layers of wire are being wound, and the other lug at an advanced position where it will engage the end of the bell crank after seven layers of wire have been wound and will then hold the layer depressed until the 8th or?nal bell crank lever 19 of the coil has been wound, such adjustment will render the machine capable of winding such a coil as is illus trated in Fig. 6. During the winding of the?rst layer the bell crank 19 will be held depressed and the clutch member 23 in en~ gagement with gear 24; the shaft section 10 will therefore be driven at the higher speed during the winding of the first layer of wire. At'the proper moment in the cycle of operations the clutch 40 will be closed and the shaft 33 will be driven by the shaft section 10 at the same high speed. This will cause the rotation of the paper measuring and feeding rolls 36 to 39, and the paper will be drawn from the roll 42 at a. corresponding speed. The clutch 40 is opened at a de?nite time in the cycle of operations whereupon, the feed of the paper stops and the gripping rolls 49 and 50 on the transfer frame close upon \the paper, the paper is severed and the upper edge of the severed sheet is carried forward into a position to be injected and fed into the wind ing. At the same time that the clutch mem ber 23 is thrown to the left the gear 63 and rod 62 is thrown to the right and the verti cal thrust rod 65 are elevated to slightly raise the end of pawl 59. This causes the step 60 in cam 58 to be presented to the end of the pawl sooner than it would if the pawl had not been elevated. and the transfer frame is caused to move forward vto engage the friction gears 52 and 9 and the sheet of paper is injected into the winding earlier *than otherwise would be the case. The high gear remains in mesh and the pawl 59 re mains elevated as long as the lug 18 is hold 125 ing the bell crank lever 19 depressed, and 1 as stated, in the present instance, this con tinues through the winding of the?rst two layers of wire. When two layers have been completed the lug 18 passes beyond the end 130

7 I of the lever 19 allowing the latter torise and reverse the position of the clutch mem ber 23 and thus reduce the speed of shafé section 10 so that during the windin 0 the next succeeding layers the paper eed ing rollers 36, 37, 38 and 39 do not run so fast and less paper is drawn from the roll 42. The shorter sheet of paper is presented to the winding spindle in the same manner as the longer sheet but the instant of injec tion in the winding is slightly later than before because the pawl 59 has not been lift ed and the step 60 does not arrive at the end of the pawl so early in the cycle of operations. The shorter sheet thus produced is, in the coil under consideration, only long enough to a?'ord three wrappings around the helix. A corresponding short length of paper is thus measured off during the for mation of each succeeding'wire layer until the second lug 18 again depresses the end of bell crank lever 19 whereupon the speed of the paper feeding mechanism again changes and sufficient paper, is measured off each time for six wrappings until the coil is?nished.- It is of course understood that the lugs 18 may be located at various positions upon the periphery of the clutch member 17 and that each lug maybe of a lengthcor responding to one or more of the steps of movement of the clutch member, all depend ing upon the locations in the coil where the amount of insulation is to be increased or decreased and upon the total number of layers in the coil. It will be seen that inasmuch as the clutch 40 is closed at the same point in the cycle of operations and likewise opened at the same point in each cycle, in order to vary the length of paper fed, it is necessary to.vary the rapidity of the feed and that is what is accomplished by the change speed gear introduced in the shaft 10. A variable Memos length of paper also necessitates a variable time to Wind it upon the spindle and this is provided for by commencing to Wind the longer sheets earlier than the shorter sheets since it is desirable to have the trailing edge of all sheets enter the coil at a given in stant and with respect to the moment of reversal of the wire lead at the end of a layer. I claim: ' _ 1. In a winding machine, the combination of a winding spindle, mechanism for wind- ing strand material in successive superposed layers thereon to form va helix and mech-. anism for winding sheet materiallbetween the layers and for varying the number of turns thereof between the adjacent layers of the same helix. 2. In a winding machine, the combination of a winding spindle, means for continu- ously feeding strand material thereto, means for intermittently feeding sheet material thereto during the feeding of the strand ma; terial and means for increasing or decreas ing the length of succeeding sheets of the sheet material. 3. In a winding machine, the combination of a winding spindle, means for continuously winding strand material thereon in super posed layers, means for feeding sheet ma terial intermittently to the spindle, the dura tion of the feedin periods of which are uni form, and means for varying the rapidity of feed during selected periods. 4. In a winding machine, the combination of a winding spindle, means for presenting individual sheets of material at regular in tervals to be wound thereon, feeding and measuring mechanism for predetermining the length of said individual sheets and means for varying the speed of the feeding _ and measuring mechanism with respect to that of the spindle. 5. In a winding machine, the combination of a winding spindle driven at uniform speed, means for predeterminino- the length of individual pieces of material to be suc cessively wound upon the spindle and means for feeding different lengths of said mate rial in uniform periods of time..6. In a winding machine, the combination of a winding spindle, means for winding su~ perposed layers of strand material thereon and variable speed mechanism for drawing from a continuous web portions thereof of varying length and means for winding such portions between the adjacent layers of strand material. 7. In a winding machine, a winding spin dle, mechanism for winding strand material in successive superposed layers thereon, means for presenting individual sheets of sheet material at regular intervals to be wound thereon, feeding and measuring rolls for predetermining the length of the indi _ 105 vidual sheets, a rotary shaft through which I said rolls are actuated, means for intermit 110 tently throwing said rolls into and out of operative relation to said shaft, a change speed device for said shaft, and automatic means for throwingr the same into and out of operation. at predetermined intervals In a winding machine, the combination of a winding spindle, means for continuous ly' feeding strand material thereto, means for intermittently feeding sheet material thereto during the feeding of the strand ma terial, means for increasing or decreasing the length of succeeding sheets of the sheet material and means for varying the time of presentation of the sheet material to the spindle.. 9. In a winding machine, the combination of a winding'spindle, means for continuously winding strand material thereon in super posed layers, means for feeding sheet mate rial intermittently to the spindle, the dura V 120' 130

8 1,427,509 S tion of the feeding periods of which are uni form, means for varying the rapidity of feed during selected periods and means for vary ing the time of presentation of the sheet ma terial to the spindle. 10. In. a winding machine, the combina tion of a winding spindle, means for pre senting individual sheets of material at reg ular intervals to be-wound thereon, feeding and measuring mechanism for predetermin ing the length of said individual sheets, means for varying the speed of the feeding and measuring mechanism with respect to that of the spindle and means for varying the time of presentation of the sheets to the spindle In a winding machine, the combina tion of a winding spindle driven at uniform speed, means for predetermining the length of individual pieces of material to be suc cessively wound upon the spindle, means for feeding different lengths of said material in uniform periods of time and means for vary ing the time of presentation of the pieces of material to the spindle. ~ 12. In a winding machine, the combina tion of a uniformly rotating winding spin dle, means for successively presenting pieces of winding material to the spindle, means for increasing or decreasing the length of said pieces during the operation of the ma chine and means for varying the time of pre~ sentation of said pieces to the spindle in accordance with the length thereof. 13. In a winding machine, the combina tion of a winding spindle, means for wind! ing superposed layers of strand material thereon and variable speed mechanism for drawing from a continuous web portions thereof of varying length, means for wind ing such portions between the adjacent lay ers of strand material and means for vary ing the time of presentation of said portions» to the spindle. 14. In a winding machine, a winding spin dle, feeding and measuring mechanism for sheet material to be wound.upon said spin dle, means for varying the speed of opera tion of said mechanism, injecting mechanism for presenting the sheet material to said spindle, and means for varying the time of operation of said injecting mechanism, whereby the latter will operate early or late in the cycle of operations of the machine in accordance with the length of sheet material introduced. 15. In a winding machine, a winding spin dle, means for continuously feeding strand material thereto, feeding and measuring rolls for individual sheets of material to be wound on said spindle, injecting mechanism for in troducing said sheets between the layers of strand material, means for varying the speed of the feeding and measuring rolls, and means for varying the time of operation of said injecting mechanism, whereby the lat ter will operate early or late in the cycle of operations of the machine- in accordance with the length of the sheet material intro duced. 16. In a winding machine, the combina tion of a winding spindle, means for wind ing strand material in superposed layers upon said spindle, means for feeding vary ing lengths of sheet material towards the spindle, a sheet material injecting mecha nism adapted to introduce the lengths of sheet material between the layers of strand material and means for varying the time of operation of said injecting mechanism where by the same will operate early or late in the cycle of operations of the machine depend ing upon the length of the sheet material in troduced. In witness whereof, I hereunto subscribe my signature. JAMES c. ANDERSON

Az Z 1.357,665. Azzee/2Z27. Patented Nov. 2, y 24-cee?, A-6. vy

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

"(2.4% May 4, 1954 C. A. GUSTAFSON 2,677,202. Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet CAR. A.

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

1,702,475. Feb. 19, , F. FAHNG COIL WINDING MACHINE Filed June 27, sed. 3. Sheets-Sheet 1 INVENTOR WITNESSES: 6%s/fcA.

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Feb. 14, 1967 R. B. WENGER 3,304,094 CLIMBING WHEEL CHAIR A/C. Z. 5 is INVENTOR. a/caezo as a 7/gate, 57 d. 2. XO aoz. 1277aatavays.

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

& 9. Š. Aerary 4. Morazzzzzok. May 19, : 1,538,208. INVENTORS INTERNAL COMBUSTION MOTOR. atz Aazzzz c1. A1arclaezzf H. A. NORDWICK E. A.

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

uranayasa NNN (226er? Z /zcz-az77a 7-z Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING ZZZZZZZZA SSXSSSSSSSSSSS 50 \... "...

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

Aug. 18, H. C. H. WASH ET AL 2,051,116 POWER PRESS DRIVING MECHANISM. Zezezézy. 6.2%zz & WZ

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

May 7, ,199,501. J. MacBLANE SAFETY DEVICE FOR PUNCH PRESSES. Filed May 24, Sheets-Sheet INVENTOR. utarres?eat

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

April 22, 1969 R. R. MYERS 3,439,368 SWIMMING POOL CLEANER. Filled Jan. 3, //V/AA/7OA. aaaaya /7 a.a5. As / Al-Aza 47.4% r-77%---a A77 oawals

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0251883 A1 WANG US 2016O251883A1 (43) Pub. Date: Sep. 1, 2016 (54) LOCKING AND UNLOCKING MECHANISM FOR ADOOR LOCK (71) Applicant:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0251883 A1 WANG US 2016O251883A1 (43) Pub. Date: Sep. 1, 2016 (54) LOCKING AND UNLOCKING MECHANISM FOR ADOOR LOCK (71) Applicant:

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 3-vi-ucvtot 21, 6)) 7/4-ee-d

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

UNITED STATES PATENT OFFICE

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

1, Patented Sept. 5, J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, SHEETS-S HEET 1..

1,197.534. J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, 1915. Patented Sept. 5, 1916. 4. SHEETS-S HEET 1.. - if Amiris PETERs co., PHoro-it-yo. was ico. o. c. 1,197.534. J, A, NORTON. RRGANG

1,197.534. J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, 1915. Patented Sept. 5, 1916. 4. SHEETS-S HEET 1.. - if Amiris PETERs co., PHoro-it-yo. was ico. o. c. 1,197.534. J, A, NORTON. RRGANG

F. C. DU GRENIER ET AL 2,323,981. July 13, COIN- CONTROLLED WENDING MACHINE. 5 Sheets-Sheet li. Filed July 28, 194l. 1??

July 13, 1943. F. C. DU GRENIER ET AL 2,323,981 COIN- CONTROLLED WENDING MACHINE Filed July 28, 194l 5 Sheets-Sheet li 1??ks**** July 13, 1943. F. C. DU GRENIER ET AL 2,323,981 COIN- CONTROLLED WENDING

July 13, 1943. F. C. DU GRENIER ET AL 2,323,981 COIN- CONTROLLED WENDING MACHINE Filed July 28, 194l 5 Sheets-Sheet li 1??ks**** July 13, 1943. F. C. DU GRENIER ET AL 2,323,981 COIN- CONTROLLED WENDING

Zy <a (6- S32 %24 rx 2 -- EE N7 EEa WEF ase2/zes 4. Zafayer & WA 2-6-, &B 467. ZO s e \\\ Ec

June, 1933. S. A. DAAGER POWER TAKE-OFF Filed Dec. 31, 1931 2 Sheets-Sheet l ZO 7. 227 6. & WA 2-6-, Z S32 %24 rx 2 -- EE N7 EEa 26. - s e \\\ Ec M N EA ty. title WEF - 27.47 2. ase2/zes 4. Zafayer Zy

June, 1933. S. A. DAAGER POWER TAKE-OFF Filed Dec. 31, 1931 2 Sheets-Sheet l ZO 7. 227 6. & WA 2-6-, Z S32 %24 rx 2 -- EE N7 EEa 26. - s e \\\ Ec M N EA ty. title WEF - 27.47 2. ase2/zes 4. Zafayer Zy

Feb. 1, 1955 L BENNETT EA 2,701,005 CURB CLIMBING WHEEL CHAIR () INVENTORS. Sssa ()n& Nanx * manaya w N w ww.u. S.S.S.

Feb. 1, 19 L BENNETT EA 2,701,00 CURB CLIMBING WHEEL CHAIR Filed June 23, 194 3. Sheets-Sheet ey & () INVENTORS Sssa ()n& Nanx * manaya w N w ww.u. S.S.S. A77aarawieys Feb. 1, 19 L, BENNETT E. A. 2,701,00

Feb. 1, 19 L BENNETT EA 2,701,00 CURB CLIMBING WHEEL CHAIR Filed June 23, 194 3. Sheets-Sheet ey & () INVENTORS Sssa ()n& Nanx * manaya w N w ww.u. S.S.S. A77aarawieys Feb. 1, 19 L, BENNETT E. A. 2,701,00

June 6, ,987,128 W. KREG SOIL, DAMMING IMPLEMENT. Filed June ll, Sheets-Sheet. Werner Arieg INVENTOR. &&. ~~~~

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, SHEETS-SHEET 1. is a 12, WITVESSES. -é (?

1,229,352, C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, 1917. 3 SHEETS-SHEET 1. v NS \SS : is a 12, WITVESSES -é (?4-le-4 Szé-- 47 TORNEY. C. E. WAN NORMAN, & &S S

1,229,352, C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, 1917. 3 SHEETS-SHEET 1. v NS \SS : is a 12, WITVESSES -é (?4-le-4 Szé-- 47 TORNEY. C. E. WAN NORMAN, & &S S

Nov. 19, 1963 W. J. LEE 3,111,246 SHIRT FOLDING MACHINE Filed May ll, Sheets-Sheet 1 INVENTOR. by A-4,5- anzawy &Arafat

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

March 17, 1970 H. SIGLE 3,500,75

March 17, 1970 H. SIGLE 3,500,75 WARIABLE CAPACITY FUEL NJECTION PUMP FOR FUEL COMBUSTION OPERATED PILE DRIVER Filed June 3, 1968 2. Sheets-Sheet combustion Chamber March 17, 1970 H. SIGLE 3,500,752 -

March 17, 1970 H. SIGLE 3,500,75 WARIABLE CAPACITY FUEL NJECTION PUMP FOR FUEL COMBUSTION OPERATED PILE DRIVER Filed June 3, 1968 2. Sheets-Sheet combustion Chamber March 17, 1970 H. SIGLE 3,500,752 -

(12) United States Patent

USOO8384329B2 (12) United States Patent Natsume (54) (75) (73) (*) (21) (22) (65) (30) (51) (52) (58) WIPER SYSTEMAND WIPER CONTROL METHOD Inventor: Takashi Natsume, Toyohashi (JP) Assignee: ASMO Co.,

USOO8384329B2 (12) United States Patent Natsume (54) (75) (73) (*) (21) (22) (65) (30) (51) (52) (58) WIPER SYSTEMAND WIPER CONTROL METHOD Inventor: Takashi Natsume, Toyohashi (JP) Assignee: ASMO Co.,

58) Field of Search...74/512,513,519, References Cited. UNITED STATES PATENTS 3,151,499 10/1964 Roe X

United States Patent Gibas ". 54 ADJUSTABLE CONTROL PEDALS FOR WEHICLES 72 inventor: Jack E. Gibas, Essexville, Mich. (73) Assignee: General Motors Corporation, Detroit, Mich. 22 Filed: May 26, 1970 (21)

United States Patent Gibas ". 54 ADJUSTABLE CONTROL PEDALS FOR WEHICLES 72 inventor: Jack E. Gibas, Essexville, Mich. (73) Assignee: General Motors Corporation, Detroit, Mich. 22 Filed: May 26, 1970 (21)

United States Patent (19) shioka et al.

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

No. 714,412. Patented Nov. 25, C. P. SEN METZ. INDUCTION MOTOR. Application filed Mar. 22, 1900.) (No Mode.) 2 Sheets-Sheet. N.W. S.

No. 714,412. Patented Nov., 1902. C. P. SEN METZ. INDUCTIN MTR. Application filed Mar. 22, 1900.) (No Mode.) 2 Sheets-Sheet. N.W. S. - S N N SS s N N 2 ES Ese V SS His S. NS i SS Sir still All 2 H2SHA

No. 714,412. Patented Nov., 1902. C. P. SEN METZ. INDUCTIN MTR. Application filed Mar. 22, 1900.) (No Mode.) 2 Sheets-Sheet. N.W. S. - S N N SS s N N 2 ES Ese V SS His S. NS i SS Sir still All 2 H2SHA

United States Patent (19) Jarrett

United States Patent (19) Jarrett 11. Patent Number: 45 Date of Patent: Apr. 23, 1985 (54 COMPOUND LEVER BOW 76) Inventor: David W. Jarrett, 901 Sunset Dr., Lexington, Va. 40502 (21) Appl. No.: 370,036

United States Patent (19) Jarrett 11. Patent Number: 45 Date of Patent: Apr. 23, 1985 (54 COMPOUND LEVER BOW 76) Inventor: David W. Jarrett, 901 Sunset Dr., Lexington, Va. 40502 (21) Appl. No.: 370,036

% Y 2. (12) Patent Application Publication (10) Pub. No.: US 2012/ A1. (19) United States. (43) Pub. Date: Aug. 30, Tanaka et al.

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0216645 A1 Tanaka et al. US 20120216645A1 (43) Pub. Date: Aug. 30, 2012 (54) WORM WHEEL (75) Inventors: Yosuke Tanaka, Saitama

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0216645 A1 Tanaka et al. US 20120216645A1 (43) Pub. Date: Aug. 30, 2012 (54) WORM WHEEL (75) Inventors: Yosuke Tanaka, Saitama

2,376,968. May 29, F. M. JONES TWO-CYCLE GAS ENGINE. 2 Sheets-Sheet li. Filed Dec. 26, 1942 FIG, vucinto FREDERICK M. JONES.

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

July o. E. COTE 2,324,767 VARIABLE CAM MECHANISM. Filed April 17, Sheets-Sheet 1. i" J5 g. zal INVENTOR. ÚmefE'. 02%, _ .

July 20 1943. o. E. COTE 2,324,767 VARIABLE CAM MECHANISM Filed April 17, 1942 4 Sheets-Sheet 1 i,6/ i" J5 g zal In Il BY INVENTOR ÚmefE'. 02%, _. MM ATTORNEY. ' July 20, 1943.4. ` o. E. 'COTE VARIABLE

July 20 1943. o. E. COTE 2,324,767 VARIABLE CAM MECHANISM Filed April 17, 1942 4 Sheets-Sheet 1 i,6/ i" J5 g zal In Il BY INVENTOR ÚmefE'. 02%, _. MM ATTORNEY. ' July 20, 1943.4. ` o. E. 'COTE VARIABLE

United States Patent (19) Priede

United States Patent (19) Priede 11 Patent Number: Date of Patent: Feb. 2, 1988 54 CLOCKSPRING INTERCONNECTOR 75 Inventor: Lorenz H. Priede, Valparaiso, Ind. 73 Assignee: Method Electronics, Inc., Chicago,

United States Patent (19) Priede 11 Patent Number: Date of Patent: Feb. 2, 1988 54 CLOCKSPRING INTERCONNECTOR 75 Inventor: Lorenz H. Priede, Valparaiso, Ind. 73 Assignee: Method Electronics, Inc., Chicago,

United States Patent (19)

United States Patent (19) Berry et al. 54 STROLLER WHEEL ASSEMBLY FOR BICYCLE TRALER (75) Inventors: Peter B. Berry; Bruce W. Creps; Donald A. George, all of Eugene; Edward F. Russell, Veneta, all of Oreg.

United States Patent (19) Berry et al. 54 STROLLER WHEEL ASSEMBLY FOR BICYCLE TRALER (75) Inventors: Peter B. Berry; Bruce W. Creps; Donald A. George, all of Eugene; Edward F. Russell, Veneta, all of Oreg.

Dec. 31, A. R. KRAUSE ET AL 1,741,635 TREAD MEASURING AND CUTTING DEVICE. y EITDF is Arnold / A?ia use. //Ate C. WZirsch. By sae.

Dec. 31, 1929. A. R. KRAUSE ET AL 1,741,63 TREAD MEASURING AND CUTTING DEVICE Filed June 22, 1927 4. Sheets-Sheet l y EITDF is Arnold / A?ia use //Ate C. WZirsch By sae. Allys Dec. 31, 1929. 1,741,63 A.

Dec. 31, 1929. A. R. KRAUSE ET AL 1,741,63 TREAD MEASURING AND CUTTING DEVICE Filed June 22, 1927 4. Sheets-Sheet l y EITDF is Arnold / A?ia use //Ate C. WZirsch By sae. Allys Dec. 31, 1929. 1,741,63 A.

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

3 23S Sé. -Né 33% (12) United States Patent US 6,742,409 B2. Jun. 1, (45) Date of Patent: (10) Patent No.: 6B M 2 O. (51) Int. Cl...

(12) United States Patent Blanchard USOO6742409B2 (10) Patent No.: (45) Date of Patent: Jun. 1, 2004 (54) DEVICE FORTRANSMISSION BETWEEN A PRIMARY MOTOR SHAFT AND AN OUTPUT SHAFT AND LAWN MOWER PROVIDED

(12) United States Patent Blanchard USOO6742409B2 (10) Patent No.: (45) Date of Patent: Jun. 1, 2004 (54) DEVICE FORTRANSMISSION BETWEEN A PRIMARY MOTOR SHAFT AND AN OUTPUT SHAFT AND LAWN MOWER PROVIDED

F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, , SHEETS-SHEET 2. ssna

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

USOOS239155A. United States Patent (19) 11 Patent Number: 5,239,155 Olsson (45) Date of Patent: Aug. 24, 1993

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

June 25, 1968 ROTH 3,389,738 WINDOW SHADE APPARATUS FG. 2ASE. 4b. NVENTOR LEO ROTH. was 11- a-40, 2.11u1 2y 7. A2-2.1a-42a (arte?. ATTORNEYS.

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

United States Patent (19)

United States Patent (19) Belanger et al. 4 MECHANISM FOR GLUE GUN (76) Inventors: (21) 22 (1) 2) 8 (6) Richard W. Belanger, 2 Collins St., Amesbury, Mass. 01913; Peter S. Melendy, 11 Crestview Dr., Exeter,

United States Patent (19) Belanger et al. 4 MECHANISM FOR GLUE GUN (76) Inventors: (21) 22 (1) 2) 8 (6) Richard W. Belanger, 2 Collins St., Amesbury, Mass. 01913; Peter S. Melendy, 11 Crestview Dr., Exeter,

United States Patent (19)

United States Patent (19) Fujimoto (54) PROPELLING DRIVE TRANSMISSION STRUCTURE FORWALKING OPERATOR TYPE LAWN MOWER (75) Inventor: Satoshi Fujimoto, Sakai, Japan 73) Assignee: Kubota Ltd., Osaka, Japan

United States Patent (19) Fujimoto (54) PROPELLING DRIVE TRANSMISSION STRUCTURE FORWALKING OPERATOR TYPE LAWN MOWER (75) Inventor: Satoshi Fujimoto, Sakai, Japan 73) Assignee: Kubota Ltd., Osaka, Japan

2,835,125 LATCHING MECHANISM. 3. Sheets-Sheet 2 NII N bel2. gy:jip 72UL. ali?i. 2%. s: 2. t. NU 2z, Z z? Azózzee/

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

HHRH. United States Patent (19) Lissaman et al. (11) Patent Number: 5,082,079 (45) Date of Patent: Jan. 21, 1992 (51) (54) (75) (73)

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

No. 858,740, :, PATENTED JULY 2, G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I.

No. 858,740, :, PATENTED JULY 2, 1907. G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I. No, 858,740, PATENTED JULY 2, 1907. G, J, MEYER, SOAK TANK APPARATUS,

No. 858,740, :, PATENTED JULY 2, 1907. G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I. No, 858,740, PATENTED JULY 2, 1907. G, J, MEYER, SOAK TANK APPARATUS,

No.sse,*****<<<<<<<<<<<<

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

April 24, 1951 LE ROY S. schell, JR 2,550,500

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

?????????? 24,??: Aug. 12, ulazca S. CoMA/asa BY) J. S. CONNER 2,425,306. Filed April 26, 1945 INVENTOR. 2 Sheets-Sheet l

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

June 19, 1962 v. P. DoNNER 3,039,212 HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS

June 19, 1962 v. P. DoNNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS Filed July ll, 1960. Sheets-Sheet l June 19, 1962 3,039,212 V. P. DONNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR

June 19, 1962 v. P. DoNNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS Filed July ll, 1960. Sheets-Sheet l June 19, 1962 3,039,212 V. P. DONNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR

2. LAI A N V. United States Patent (19) Armbruster. (11 Patent Number: 4,817,483 (45) Date of Patent: Apr. 4, 1989

United States Patent (19) Armbruster 54 (76) (21) 22 51 (52) (58) 56 ELECTRICALLY POWERED DSPENSER FOR ROLLED SHEET MATERIAL HAVING A ROTARY BLADE CUTTER Inventor: Joseph M. Armbruster, 2700 NE. 47th St,

United States Patent (19) Armbruster 54 (76) (21) 22 51 (52) (58) 56 ELECTRICALLY POWERED DSPENSER FOR ROLLED SHEET MATERIAL HAVING A ROTARY BLADE CUTTER Inventor: Joseph M. Armbruster, 2700 NE. 47th St,

May 16, P. W. Olson 2,158,761 KEY CUTTING MACHINE INVENTOR: A/// / /a VV. O?sow 26.1 %44.1%

May 16, 1939. P. W. Olson 2,18,761 Filed March 2, 1937 7 Sheets-Sheet l INVENTOR: A/// / /a VV. O?sow BY 26.1 %44.1% May 16, 1939. P. W. Olson 2,18,761 Filed March 2, 1937 7 Sheets-Sheet 2 s e X y INVENTOR

May 16, 1939. P. W. Olson 2,18,761 Filed March 2, 1937 7 Sheets-Sheet l INVENTOR: A/// / /a VV. O?sow BY 26.1 %44.1% May 16, 1939. P. W. Olson 2,18,761 Filed March 2, 1937 7 Sheets-Sheet 2 s e X y INVENTOR

TEPZZ 7 Z4_ZA_T EP A1 (19) (11) EP A1 (12) EUROPEAN PATENT APPLICATION. (43) Date of publication: Bulletin 2014/20

(19) TEPZZ 7 Z4_ZA_T (11) EP 2 730 410 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 14.05.2014 Bulletin 2014/20 (21) Application number: 13191611.6 (22) Date of filing: 05.11.2013 (51)

(19) TEPZZ 7 Z4_ZA_T (11) EP 2 730 410 A1 (12) EUROPEAN PATENT APPLICATION (43) Date of publication: 14.05.2014 Bulletin 2014/20 (21) Application number: 13191611.6 (22) Date of filing: 05.11.2013 (51)

United States Patent (19)

United States Patent (19) Duvenkamp 11 Patent Number: 45 Date of Patent: 4,711,494 Dec. 8, 1987 (54. FOLDABLE HEADREST FOR VEHICLE REAR SEAT (75) Inventor: 73) Assignee: Manfred Duvenkamp, Trebur-Geinsheim,

United States Patent (19) Duvenkamp 11 Patent Number: 45 Date of Patent: 4,711,494 Dec. 8, 1987 (54. FOLDABLE HEADREST FOR VEHICLE REAR SEAT (75) Inventor: 73) Assignee: Manfred Duvenkamp, Trebur-Geinsheim,

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH. SAW MILL, No. 434,770, Patented Aug. 19, " -% -, -% (3-C 24-44/777-C- ATTORNEY.

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH No. 434,770, Patented Aug. 19, 1890. WITNESSES: INVENTOR 32" -% -, -% (3-C 24-44/777-C- ATTORNEY. (No Model.) 3. Sheets-Sheet 2. A, A, DE LOACH, No. 434,770.

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH No. 434,770, Patented Aug. 19, 1890. WITNESSES: INVENTOR 32" -% -, -% (3-C 24-44/777-C- ATTORNEY. (No Model.) 3. Sheets-Sheet 2. A, A, DE LOACH, No. 434,770.

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0072365A1 DNULOVC et al. US 2016.0072365A1 (43) Pub. Date: (54) (71) (72) (21) (22) (86) (30) COMMUNICATION DEVICE Applicant:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0072365A1 DNULOVC et al. US 2016.0072365A1 (43) Pub. Date: (54) (71) (72) (21) (22) (86) (30) COMMUNICATION DEVICE Applicant:

L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, ??424,446? 3 SHEETS-SHEET?? ??? No.r. ?vvivevsbot

??424,446? L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, 1919. Patented Aug. 1, 1922. 3 SHEETS-SHEET?? No.r??? ZA 99??vvivevsbot 1,424,446. L, R, BUCKEN DALE. EPICYCLIC POWER TRANSMISSION,

??424,446? L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, 1919. Patented Aug. 1, 1922. 3 SHEETS-SHEET?? No.r??? ZA 99??vvivevsbot 1,424,446. L, R, BUCKEN DALE. EPICYCLIC POWER TRANSMISSION,

April 15, ,438,641. B. M., BRADEY STAIR CLIMBING WHEELCHAIR. / of 5. Filed March 3, Sheet INVENTOR. 4227%% / aezaze %2-4- ATTORNEY

April 15, 1969 Filed March 3, 1966 B. M., BRADEY STAIR CLIMBING WHEELCHAIR Sheet. / of 5 5. BY 2 4227%% / aezaze 2 %2-4- ATTORNEY April 15, 1969 Filed March 31, 1966 B, M, BRADLEY STAIR CLIMBING WHEELCHAIR

April 15, 1969 Filed March 3, 1966 B. M., BRADEY STAIR CLIMBING WHEELCHAIR Sheet. / of 5 5. BY 2 4227%% / aezaze 2 %2-4- ATTORNEY April 15, 1969 Filed March 31, 1966 B, M, BRADLEY STAIR CLIMBING WHEELCHAIR

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

April 3, W. O. BENNETT, JR 2,372,757 TIMING DEVICE INVENTOR. WILLIAM O.BENNETT JR. 2. 2ázan/ ATTORNEYS.

April 3, 194. W. O. BENNETT, JR 2,372,77 TIMING DEVICE Filed Dec. 19, l94l 3. Sheets-Sheet l INVENTOR. WILLIAM O.BENNETT JR BY 2. 2ázan/ ATTORNEYS. April 3, 194. W. O. BENNETT, JR TIMING DEVICE 2 372,77

April 3, 194. W. O. BENNETT, JR 2,372,77 TIMING DEVICE Filed Dec. 19, l94l 3. Sheets-Sheet l INVENTOR. WILLIAM O.BENNETT JR BY 2. 2ázan/ ATTORNEYS. April 3, 194. W. O. BENNETT, JR TIMING DEVICE 2 372,77

April 5, G, E, SWANSON 2,113,007 CYLINDER LOCK. NS: S.S.S.S.S Né EEE SS W. a. <SNSSSSSSSS/fde. is E( 4 NN. p7 NSN NNNN N&zo 76 v7 /6 2/23 / NS

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

3.s. isit. United States Patent (19) Momotet al. 2 Šg. 11 Patent Number: 4,709,634 (45) Date of Patent: Dec. 1, Zxx (54) (75) (73)

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

?o- Ø Antonio Aw/zza2SE). July 18, 1967 A. F. PASCUA 3,331,479 ATTORNEY PEDAL CONTROL FOR AUTOMOBILES NVENTOR

July 18, 1967 A. F. PASCUA SYSTEM OF COMBINED ACCELERATOR AND BRAKE Filed Aug. 18, l965 PEDAL CONTROL FOR AUTOMOBILES 2 Sheets-Sheet NVENTOR Antonio Aw/zza2SE).?o- Ø. 4.2. ATTORNEY July 18, 1967 A. F.

July 18, 1967 A. F. PASCUA SYSTEM OF COMBINED ACCELERATOR AND BRAKE Filed Aug. 18, l965 PEDAL CONTROL FOR AUTOMOBILES 2 Sheets-Sheet NVENTOR Antonio Aw/zza2SE).?o- Ø. 4.2. ATTORNEY July 18, 1967 A. F.

United States Patent (19) Muranishi

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

P, H, LACEY, DOOR OPERATING MECHANISM, APPLICATION FLE) UNE 5, 1918, 41,039, Patented Mar. 28, WITNESSES: Q I//E/TOR

P, H, LACEY, DOOR OPERATING MECHANISM, APPLICATION FLE) UNE 5, 1918, 41,039, Patented Mar. 28, 1922. 6 SHEETS-SHEET, N WITNESSES: Q I//E/TOR ap-4. - N Z 22222 ZZZZZzce2/ 72e2-22-sa AfroREY P, H, LACEY,

P, H, LACEY, DOOR OPERATING MECHANISM, APPLICATION FLE) UNE 5, 1918, 41,039, Patented Mar. 28, 1922. 6 SHEETS-SHEET, N WITNESSES: Q I//E/TOR ap-4. - N Z 22222 ZZZZZzce2/ 72e2-22-sa AfroREY P, H, LACEY,

March 27, 1956 T. A. DOURDEVILLE 2,739,366

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

BY 4. earea Carence A. Aroppe/ INVENTOR. Afg. 5

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

United States Patent (19)

United States Patent (19) Ryder 54 RUN FLAT DEVICE FOR TRES 75 Inventor: John Charles Ryder, Doylestown, Ohio 73 Assignee: The Firestone Tire & Rubber Company, Akron, Ohio 22 Filed: Apr. 3, 1970 (21) Appl.

United States Patent (19) Ryder 54 RUN FLAT DEVICE FOR TRES 75 Inventor: John Charles Ryder, Doylestown, Ohio 73 Assignee: The Firestone Tire & Rubber Company, Akron, Ohio 22 Filed: Apr. 3, 1970 (21) Appl.

Aug. 11, Wa/ace M. Brown. W. M. BROWN 2,648,392 DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 INVENTOR: 2 Sheets-Sheet l

Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 2 Sheets-Sheet l BY INVENTOR: Wa/ace M. Brown Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS

Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 2 Sheets-Sheet l BY INVENTOR: Wa/ace M. Brown Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS

Q/% fajwzl/y/f. a. a; %M f. Patented Get. 23, SHEETS SHEET I. awvwalto'a. W. S. Tall/WEE.v CIRCUIT BREAKER. Zé ~~

W. S. Tall/WEE.v CIRCUIT BREAKER. APPLICATION FILED sumac, x915. Patented Get. 23, 1917. 2 SHEETS SHEET I. Zé ~~ w'kmeobeo v Q/% fajwzl/y/f. a. a; %M f awvwalto'a W. S. MAYER. CIRCUIT BREAKER. APPLICATION

W. S. Tall/WEE.v CIRCUIT BREAKER. APPLICATION FILED sumac, x915. Patented Get. 23, 1917. 2 SHEETS SHEET I. Zé ~~ w'kmeobeo v Q/% fajwzl/y/f. a. a; %M f awvwalto'a W. S. MAYER. CIRCUIT BREAKER. APPLICATION

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 2015 0084494A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0084494 A1 Tonthat et al. (43) Pub. Date: Mar. 26, 2015 (54) SLIDING RACK-MOUNTABLE RAILS FOR H05K 5/02 (2006.01)

(19) United States US 2015 0084494A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0084494 A1 Tonthat et al. (43) Pub. Date: Mar. 26, 2015 (54) SLIDING RACK-MOUNTABLE RAILS FOR H05K 5/02 (2006.01)

C. S. BRADLEY. ELECTRIC MOTOR. No. 439,102, Patented Oct. 28, n AA es'- Q wiza. -%%-4ge

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

May 19, 1964 AT TORNEY 3,133,451. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT. Filed Dec. 28, 196l. 3. Sheets-Sheet 1 R CHARD J.

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

March 22, 1966 R, N JANEWAY 3,241,860 TRACTOR-TRAILER FIFTH WHEEL COUPLING INVENTOR, a/ -as 224-ya // >27eeway. E. F. 2.24v. 2. -% a

March 22, 1966 R, N JANEWAY 3,241,8 TRACTOR-TRAILER FIFTH WHEEL COUPLING Filed Sept. 12, 1963 3. Sheets-Sheet l INVENTOR, a/ -as 224-ya // >27eeway E. F. 2.24v. 2. -% a 2.2.2. March 22, 1966 R, N JANEWAY

March 22, 1966 R, N JANEWAY 3,241,8 TRACTOR-TRAILER FIFTH WHEEL COUPLING Filed Sept. 12, 1963 3. Sheets-Sheet l INVENTOR, a/ -as 224-ya // >27eeway E. F. 2.24v. 2. -% a 2.2.2. March 22, 1966 R, N JANEWAY

United States. Patent (19) Clarke

United States. Patent (19) Clarke 54) VARIABLE SPEED DRIVE 76) Inventor: George C. Clarke, 9 Penfield Ave., Chatsworth, Calif. 91311 21 Appl. No.: 791,373 22 Filed: Apr. 27, 1977 51) Int. Cl... F16H /52;

United States. Patent (19) Clarke 54) VARIABLE SPEED DRIVE 76) Inventor: George C. Clarke, 9 Penfield Ave., Chatsworth, Calif. 91311 21 Appl. No.: 791,373 22 Filed: Apr. 27, 1977 51) Int. Cl... F16H /52;

10-sea /2 72/7e/ * 22%,962a. PATENTED OCT, l0, l905, No. 801,754.

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

Nov. 11, 1969 WING J. Lee 3,477,619 AUTOMATIC SHIRT FOLDING MACHINE Filed June 28, Sheets-Sheet

Nov. 11, 1969 WING J. Lee 3,477,619 Filed June 28, 1967 7 Sheets-Sheet Nov. 11, 1969 WING J. EE 3,477,619 Filed June 28, 1967 7 Sheets-Sheet 2 s S. 7 Nov. 11, 1969 WNG J. LEE 3,477,619 Filed June 28, 1967

Nov. 11, 1969 WING J. Lee 3,477,619 Filed June 28, 1967 7 Sheets-Sheet Nov. 11, 1969 WING J. EE 3,477,619 Filed June 28, 1967 7 Sheets-Sheet 2 s S. 7 Nov. 11, 1969 WNG J. LEE 3,477,619 Filed June 28, 1967

No. 801,373. PATENTED 00T, 10, J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, HEETs-SHEET. Z2562/2ZZZ Aa27/2(272, inventor

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

July 3, ,965,450 C. BROWN VEHICLE. Filed July 20, Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS

July 3,1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS July 3, 1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 2 mu x o H...H..n...m.,.,...+.,...

July 3,1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS July 3, 1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 2 mu x o H...H..n...m.,.,...+.,...

Egg SE7 4,444%, ATTYS. Dec. 22, 1964 J. W. culpepper ETAL 3,162,394 STRAP DISPENSER INVENTOR re EDWARD J STAHNKE.

Dec. 22, 1964 J. W. culpepper ETAL 3,162,394 STRAP DISPENSER Filed May 7, 1963 9 4. 5 40 4. re Egg SE7 INVENTOR. JOHNW, CULPEPPER EDWARD J STAHNKE ALVIN WINKLER 4,444%, ATTYS United States Patent Office

Dec. 22, 1964 J. W. culpepper ETAL 3,162,394 STRAP DISPENSER Filed May 7, 1963 9 4. 5 40 4. re Egg SE7 INVENTOR. JOHNW, CULPEPPER EDWARD J STAHNKE ALVIN WINKLER 4,444%, ATTYS United States Patent Office

7/22. Z62/ lazy f/2zzzaz. e- re-er- 7tee /7Zetas. Aug. 28, 1962 H. R. KILLIAN 3,050,781

Aug. 28, 1962 H. R. KILLIAN 3,050,781 MOLDED IN PLACE RUBBER SEAT BUTTERFLY WALVE Filed Aug. 28, 1959 5 Sheets-Sheet 1 e- re-er- 7tee 2. Z62/ lazy f/2zzzaz 7/22. 22222/7Zetas Aug. 28, 1962 H. R. KILLIAN

Aug. 28, 1962 H. R. KILLIAN 3,050,781 MOLDED IN PLACE RUBBER SEAT BUTTERFLY WALVE Filed Aug. 28, 1959 5 Sheets-Sheet 1 e- re-er- 7tee 2. Z62/ lazy f/2zzzaz 7/22. 22222/7Zetas Aug. 28, 1962 H. R. KILLIAN

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

Feb. 21, 1961 H. W. THORNBURG 2,972,388 WELL, DRILL PIPE-HANDLING APPARATUS. NSSESSSSSSSCz. EAN2Kwsky a. s'ba 29 Nils-l. 7 N 3I. s O --- a.

Feb. 21, 1961 H. W. THORNBURG 2,972,388 WELL, DRILL PIPE-HANDLING APPARATUS Original Filled Aug. 14, 1953 9 Sheets-Sheet i 14 PS N. c. N. FR N. treet N N rsrc==-7-27 1 NY. vy NY y if WN AY, ii N WM Ma

Feb. 21, 1961 H. W. THORNBURG 2,972,388 WELL, DRILL PIPE-HANDLING APPARATUS Original Filled Aug. 14, 1953 9 Sheets-Sheet i 14 PS N. c. N. FR N. treet N N rsrc==-7-27 1 NY. vy NY y if WN AY, ii N WM Ma

(12) United States Patent

USOO8919333B2 (12) United States Patent Miller (10) Patent No.: (45) Date of Patent: Dec. 30, 2014 (54) (71) (72) (73) (*) (21) (22) (65) (63) (60) (51) (52) (58) BALANCED PULLEYASSEMBLY FOR COMPOUND ARCHERY

USOO8919333B2 (12) United States Patent Miller (10) Patent No.: (45) Date of Patent: Dec. 30, 2014 (54) (71) (72) (73) (*) (21) (22) (65) (63) (60) (51) (52) (58) BALANCED PULLEYASSEMBLY FOR COMPOUND ARCHERY

,62?925% HLIAI ELE ) w W/////7M //, aeoww. June 17, VI/27/702A 21, 1967 N SON S. Sheet 2 of 2 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE

June 17, 1969 Filed Dec. 21, 1967 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE 3 449 914 Sheet 2 of 2 N SON S RT,62?925% HLIAI ELE ) 77VI/27/702A w W/////7M //, aeoww C2 United States Patent Office Patented

June 17, 1969 Filed Dec. 21, 1967 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE 3 449 914 Sheet 2 of 2 N SON S RT,62?925% HLIAI ELE ) 77VI/27/702A w W/////7M //, aeoww C2 United States Patent Office Patented

/z. 6. (No Model.) No. 628,161. INVENTOR. W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) AT TORNEY WNESSES:

No. 628,161. (No Model.) W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) /z. 6. WNESSES: INVENTOR BY AT TORNEY % ENORRS PETERs co, PHoro-Litho, washington, d. c. No. 628, 16. W. F. HOMMAN. SEAL

No. 628,161. (No Model.) W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) /z. 6. WNESSES: INVENTOR BY AT TORNEY % ENORRS PETERs co, PHoro-Litho, washington, d. c. No. 628, 16. W. F. HOMMAN. SEAL

2,407,010 ADAPTER HEAD FOR WELLS. Filed Aug. 8, Sheets-Sheet. Lester C. Hudson

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

Jan. 23, O. A. KEHE 2,367,682 LANDING GEAR BY-PASS WALVE. a N SS SS N NS SS M6 SS M9 O NSN y I 2 N 6. DESV at. at 2.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

(12) United States Patent (10) Patent No.: US 6, B1. Randolph et al. (45) Date of Patent: Oct. 23, 2001

USOO6307583B1 (12) United States Patent (10) Patent No.: US 6,307.583 B1 Randolph et al. (45) Date of Patent: Oct. 23, 2001 (54) THERMAL PRINTER WITH REVERSIBLE 5,795,084 8/1998 Stone. RBBON AND METHOD

USOO6307583B1 (12) United States Patent (10) Patent No.: US 6,307.583 B1 Randolph et al. (45) Date of Patent: Oct. 23, 2001 (54) THERMAL PRINTER WITH REVERSIBLE 5,795,084 8/1998 Stone. RBBON AND METHOD

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

US 2005O25344-4A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0253444 A1 Godshaw et al. (43) Pub. Date: Nov. 17, 2005 (54) AUTOMOBILE PET BED CONSTRUCTION (22) Filed:

US 2005O25344-4A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0253444 A1 Godshaw et al. (43) Pub. Date: Nov. 17, 2005 (54) AUTOMOBILE PET BED CONSTRUCTION (22) Filed:

(12) United States Patent

(12) United States Patent US007850483B2 (10) Patent No.: Siglock et al. (45) Date of Patent: Dec. 14, 2010 (54) POWER METER SOCKET TO CIRCUIT (56) References Cited BREAKER CONNECTION U.S. PATENT DOCUMENTS

(12) United States Patent US007850483B2 (10) Patent No.: Siglock et al. (45) Date of Patent: Dec. 14, 2010 (54) POWER METER SOCKET TO CIRCUIT (56) References Cited BREAKER CONNECTION U.S. PATENT DOCUMENTS

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

United States Patent 19 11) Patent Number: 5,123,673 Tame 45) Date of Patent: Jun. 23, 1992

O US005 123673A United States Patent 19 11) Patent Number: 5,123,673 Tame 45) Date of Patent: Jun. 23, 1992 (54) SEAT BELTSYSTEM FOR A VEHICLE SEAT 4,569,536 2/1986 Tsuge et al.... 280/807 4,673, 195 6/1987

O US005 123673A United States Patent 19 11) Patent Number: 5,123,673 Tame 45) Date of Patent: Jun. 23, 1992 (54) SEAT BELTSYSTEM FOR A VEHICLE SEAT 4,569,536 2/1986 Tsuge et al.... 280/807 4,673, 195 6/1987

Feb. 10, 1970 U.P. Hanson 3,494,440 DEVICE FOR MOVING HEAVY OBJECTS UP AND DOWN, STAIRS

Feb. 10, 1970 U.P. Hanson DEVICE FOR MOVING HEAVY OBJECTS UP AND DOWN, STAIRS Filed Jan. 24, 1968 3 Sheets-Sheet 1 INVENTOR. Aeer a awso/ Feb. 10, 1970 U.P. HANSON DEVICE FOR MOVING HEAVY OBJECTS UP AND

Feb. 10, 1970 U.P. Hanson DEVICE FOR MOVING HEAVY OBJECTS UP AND DOWN, STAIRS Filed Jan. 24, 1968 3 Sheets-Sheet 1 INVENTOR. Aeer a awso/ Feb. 10, 1970 U.P. HANSON DEVICE FOR MOVING HEAVY OBJECTS UP AND