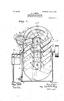

P, H, LACEY, DOOR OPERATING MECHANISM, APPLICATION FLE) UNE 5, 1918, 41,039, Patented Mar. 28, WITNESSES: Q I//E/TOR

|

|

|

- Beryl Ashlynn Jefferson

- 5 years ago

- Views:

Transcription

1 P, H, LACEY, DOOR OPERATING MECHANISM, APPLICATION FLE) UNE 5, 1918, 41,039, Patented Mar. 28, SHEETS-SHEET, N WITNESSES: Q I//E/TOR ap-4. - N Z ZZZZZzce2/ 72e2-22-sa AfroREY

2 P, H, LACEY, DOOR OPERATING MECHANISM, APPLICAON FLED JUNE 5, Patented Mar, 28, SheeTS-SHEET 2. Ø -- No.========!!!!!!!!!!!!! Ø/ Ø º: Ilyi/ENTOR. 72zzzz Z Za

3 . P, H, ACEY, D00R OPERATING MECHANISM, APPLICATION FILED JUNE 5, 1918, 1,411,089. Patented Mar, 28, SHEETS-SHEET 3, EZZZZZZZZZZZK2 SS 2IT 2. 2 Af % 2 2 N HE 2 I % INVERITOR / Zazz/Z, Zac BY al Aitofify

4 P, H, ACEY, 41,039, DOOR OPERATING MECHANISM, APPLICATION FLED JUNE 5, 1918, Patented Mar 28, SHEETS-SHEET 4, s s : li/itesses:

5 41,039, P, H, ACEY, DOOR OPERATING MECHANISM, APPLICATION FLED NE 5, 198 Patented Mar, 28, SHEETS-SHEE 5. 62/ 62% TTTTTTTTTTTTTTTTTTTTTIIN?IIIIIIIIIIIII =ae? Tb No.===~:=~ øºº &

6 P, H, ACEY, D00R OPERATING MECHANISM. APPLICATION FILED JUNE 5,

7 O UNITED STATES PAUL H. LACEY, of CHICAGO, ILLINOIS, ASSIGNOR, TO PEERLESS. DOOR, CONTROL COMPANY, OF CHICAGO, ILLINOIS, A CORPORATION. 1,411,039. To all whom it may concern. Be it known that I, PAUL H. LACEY, a citizen of the United States, and a resident of Chicago, in the county of Cook and State of Illinois, have invented certain new and useful Improvements in Door - Operating Mechanism; and I do hereby declare that the following is a full, clear, and exact de Scription thereof, reference being had to the accompanying drawings, and to the char acters of reference marked thereon, which form a part of this specification. This invention relates to a novel means for operating doors, windows, or other like closures, both swinging and sliding closures, and relates in part to novel operating mech anism for giving motion to the closure to Open and close the same, either manually or by motor power, and in part to novel means for so controlling the closure opening and closing means from a distant point or points of control located at a suitable station or stations in the building. In the embodiment which is here chosen to illustrate the principles of my invention, the invention is shown as applied to operate a horizontally sliding door or doors and a horizontally swinging door or doors, al though it will be understood that the prin ciples of the invention may be applied to operate doors which open and close in a di rection other than horizontal. The invention consists of the combination and arrangement of the parts shown in the drawings and described in the specification, and pointed out in the appended claims. A useful application of the operating mechanism is to the doors of garages, freight houses, warehouses, and other buildings where it is convenient and desirable to open and close the doors from a distant point or points of control, and in the following de tailed description of the embodiment of the invention herein disclosed, reference will be made specifically to the sliding and swinging doors shown. It is to be understood that such reference is for convenience of par ticular and explicit explanation of the form of the invention shown and is not intended to be restrictive as to the scope of the inven tion in its broader phase. Among the objects of the invention is to Door-OPERATING MECHANISM. Specification of Letters Patent. Patented Mar. 28, Application filed June 5, Serial No. 238,265. provide a novel door operating mechanism which is constructed, and arranged to posi tively open and close the door or doors, the construction and arrangement being such as to avoid lost motion between the motor which operates the mechanism and the door or doors which are to be opened and closed. Another object of the invention is to pro vide a novel apparatus for operating the door or doors which is constructed with means to disconnect the door from the oper ating mechanism at both the opening and closing limits of movement of the door or doors so as to thereby avoid throwing a heavy stress on the operating mechanism in the event that the motor which drives the operating mechanism should continue to operate either because of its momentum or because of the failure of the intended means to stop its operation; and in respect of this object cf the invention a further and aux iliary object of the invention is to construct the disconnecting means so as to insure the proper connection of the operating mecha nism with the door when the door or doors are to be moved from one extreme throw towards the other direction of its move ment. Another object of the invention is to pro vide means which are constructed to oper ate in the event that the movement of the door or doors is blocked intermediate its opening or closing movement so as to there by avoid overloading the motor that drives the operating mechanism. For instance, should the door or doors upon closing clash with a vehicle or other object passing through or within the door-way, the safety device thus provided will render the motor inert to further press the door or doors to wards the obstruction. This feature of the invention as disclosed in the illustrated em bodiment consists of means between the mo tor and the operating mechanism which is so constructed as to effect a slippage of the driving connection therebetween, which slip page will be released when the obstruction has been removed. However, in respect of the broader aspect of this feature of the in vention, the safety device for this purpose may be otherwise constructed and arranged. Another object of the invention is to pro

8 60 65 vide a novel control device that is connected to the motor or its starting or stopping equipment and extends therefrom to a dis tant control station or stations, as the case may be, whereby the motor may be started from said control station or stations and after the motor has been set in operation, the mechanism will continue to be automatically operated until the door reaches the limit of O its travel towards which the motor is driv ing it; and the control means is preferably supplementally provided with automatic means whereby it is actuated at the limit of travel of the door or doors so as to ren der the motor inert to further operate the door or doors. When an electric motor is used to drive the door operating mechanism, the contol device operated from the distant station or stations will be connected to and operate a switch to open and close the motor circuit, and means traveling with the door or doors will act on the control device to open or close the motor circuit, depending upon the direction of movement of the door 25 or doors at the respective limits of said movement. Another object of the invention, in con nection with the motor driven operating mechanism referred to, is to provide a novel means for manually operating the door opening mechanism upon failure of power derived through the motor, and preferably such manually operated actuating mecha nism will embrace a prime mover that is 35 normally disconnected from the door oper ating mechanism and is adapted to be clutched or otherwise, connected thereto when the manually actuated mechanism is to be employed. 40 Another object of the invention is to pro vide means for operating the door through the medium of a suitably located rotative screw shaft or shafts, single screw shaft being employed with a single door and a 45 double screw shaft with right and left hand threads being employed in connection with double doors. In respect of the safety means to disconnect the operating mecha nism from the door or doors when a screw 50 actuating shaft is used, travelers may be threaded thereover and the screw threads discontinued at the limits of movement of the doors to provide plain sections onto which the travelers pass, and springs may 55 be provided which are placed under com pression for forcing the travelers back onto the screw threads when the shaft rotates in an opposite direction. A further object of the invention in re spect of its application to sliding doors is to provide a novel door supporting rail or track suitably shaped for operative combi nation with the door operating mechanism and tu enclose the hanger carriage and trav elers, and preferably also the screw shaft 1,411,089 for the doors, the travelers being directly connected to the carriages with the track enclosure. Other objects of the invention are to im prove and simplify operating mechanisms for doors and like closures. In said drawings, 'Figure 1 is an inside elevation of two sliding doors with my improved operating mechanism applied thereto. Figure 2 is a view partially in elevation and partially in section of a distant control device for the actuating motor of the oper ating device. Figure 3 is a plan view of a portion of the operating mechanism and its motor. Figure 4 is a section on the line 4-4 of Figure 1, looking in the direction indicated by the arrow. Figure 5 is a side elevation thereof partly in section and partly in elevation. Figure 6 is a partial vertical section on the line 6-6 of Figure 3. Figure 7 is an end elevation of the oper ating mechanism taken from the end there of to which the manually actuated device is connected. Figure 8 is a section on the line 8-8 of Figure 7. Figure 9 is an inside elevation of the up per ends of two swinging doors showing the door operating device applied thereto. Figure 10 is a plan view of a portion of the latter construction showing the door in full lines in open position. Figure 11 is a vertical section on the line of Figure 9. Figure 12 is an inside elevation of the upper ends of the sliding doors showing a modified arrangement of the operating mechanism and its door track and support. Figure 13 is an end elevation of the struc ture shown in Figure 12. First, referring to the sliding door con struction shown in Figures 1 to 8, inclusive, 14, 14 designate two sliding doors which move towards and from a central closing position to close the door opening 15, and are located, as herein shown, just inside the wall 16 (Figures 1, 3, and 7) of the build ing so as to have clearance inside said wall. 17, 17 designate hangers, two being applied and connected to the top of each door. Each of said hangers, as best shown in Figure 7, embraces a shank 17' that is connected to a U-shaped fitting 18 that fits over and is attached in any suitable manner to the upper marginal portion of its correspond ing door, and an eye 19 to receive a shaft on which bearing rollers, are mounted. 21 designates as a whole a horizontal in verted U-shaped track structure that is lo cated just inside the building wall 16 above the door opening 15. The lower marginal portions of the U-shaped structure are

9 ble manner to the inner member of the track 3,433,089 formed to provide horizontal tracks 22 on nated as a whole in Figure 1 by 41. Said which the rollers travel and, inside said bearing bracket consists of two hollow, box tracks, with upwardly extending guard like members 42, 43, Figures 3 and 6, that flanges 23 to confine the rollers in place. are detachably fixed together by means of Said track 21 is closed at its upper side and cap screws 44 to constitute a gear housing thereby constitutes an enclosed track struc for gears hereinafter Eii The inner ture which measurably protects the rollers unthreaded portions 47 of said shaft sec and the tracks 22 from the settlement of tions rotate in bushings 45 that are suitably dust and dirt thereon.. fixed in the bearing bracket 41. The screw The particular form of track, however, shaft is thus made of two sections for con may be varied to suit different installa venience of manufacturing and assembling. tions. When applied to doors already in If desirable, however, the right and left stalled the old doors will be retained and hand screw threads for double doors may the hangers and other elements constructed be formed on a single length shaft section. to be adapted to the installation. 50, 51 designate travelers that are pro Said track structure is supported from vided at their upper ends with heads 52, the wall 16 by a horizontal, generally Z 52 to receive internally threaded fixed shaped bracket 25 inside the wall 16, the bushings 53, Figure 6, that engage the right upper member 26 of which is attached, as by and left hand threaded shaft sections 36,36. means of bolts 27, to said wall. The hori Said travelers are separable from and are zontal member 28 of said bracket is con bolted, or otherwise fixed, to brackets 55 nected to the closed or intermediate por that are attached to the upper margins of tion of the track structure in any suitable the doors near their meeting edges. One manner, as by means of the bolts, and of the travelers, the traveler 51 as herein the terminal portion 31 of said bracket lies shown, is provided with an upstanding arm inside of and may be attached in any suita 56 that is adapted, at the limit of travel of the associated door, 15 to control the con structure. The foregoing construction af. nection of the motor with the door operat fords means whereby the doors 15 are sus ing mechanism in a manner hereinafter to pended from and are adapted to travel on be described. - the fixed track 21 horizontally towards and The motor 35 is connected to the right from each other.. The specific means herein shown for caus ing the doors to travel towards and from 35 each other embraces a horizontally threaded shaft which is driven by a motor 35, said motor being a reversible motor as herein shown. In the present instance, where two sliding doors are contemplated, the threaded 40 shaft embraces right and left hand screw threads, so as to cause the doors to travel away from each other in openin and to wards each other in closing the doors. If a single door be contemplated, a single 45 shaft having a thread of only one direction will be employed, in connection with the reversible motor, to cause the door to travel in opposite directions to open and close the same. 50 Referring now particularly to the double door construction and the right and left screw threaded shaft to operate the same, the construction herein disclosed is made as follows: 36, 36 designate two sections of a horizon tal shaft having right and left hand screw threads, respectively. The sections of said shaft are rotatively mounted at their outer ends in brackets 37, suitably supported from the wall structure 16, and extending in wardly therefrom. The inner or proximate ends of said shaft sections are connected by any suitable interlocking connection 40, best shown in Figure 6, and are rotatively. Sup ported in a suitable bearing bracket, desig and left hand threaded, shaft through a gearing connection that is enclosed within the housing bracket 41 made as follows: The shaft 60 of the motor 35 is connected through a suitable form of slip clutch or connection, designated as a whole by 61, with a shaft 62 that is rotatively mounted in suitable bushings 63 carried by the bear ing bracket 41. Fixed to said shaft 62 is a pinion 65 which, through an idler gear 66 rotatively mounted in the bushing 67 car ried by said bracket, is connected to and drives a gear wheel 68 that is keyed or other wise non-rotatively mounted on the meeting plane ends 47 of the shaft threaded sections. Through the gearing arrangement described, the speed of the motor to drive or rotate the shaft sections 36 is suitably reduced. The circuit of the motor 35 is controlled through the medium of a switch, designated as a whole in Figures 1 and 6 by 70, and illustrated in detail in Figures 3 and 6. Said switch, as illustrated in said last men tioned figures, embraces in its construction two pairs of terminals 71, 72 suitably con nected to the reversible motor and are sup ported on a base 73 of any suitable insulat ing material. These terminals are splitter minals to receive the ends of rocking switch blades 74 that are pivoted at 75 to brackets 76 mounted on the base 73. The said switch blades 74 are connected in any suitable man ner to a switch actuating block 77, said blades 74 being herein shown as fixedly con &

10 nected to the block. The block is adapted for movement in directions parallel to the planes of the blades 74 so that when moved in one direction it and the blades 74 are oscillated to bring the ends of the blades 74 into contact with one of the pairs of ter minals 71, and when moved in the other direction to bring the other ends of said blades into contact with the other pairs of terminals 72. The means herein shown for actuating the switch block are made as fol lows:, 81 designate. the two leads of what may be considered an endless cable that are normally taut and connected, respectively, through the medium of eye bolts 82, 83 (Figure 6) to the opposite sides of the switch block 77. The lead is trained di rectly from its attachment to the switch block 77 over a guide pulley 85 (Figure 1) to and about a drum 86 that is rockingly mounted on a shelf 87 (Figure 2) supported on a bearing 88 that is located at any suit able control station about the building. The said lead is wound about the drum 86 and continues, as the lead 81, from said drum over guide pulleys 90, 91, 92 (Fig ures 1 and 6) to its connection with the at taching eye bolt 83 at one of the switch block 77. The drum 86 is rocked on the shaft 87 through the medium of an operat ing lever 94 (Figures 1 and 2) that is at tached to or made integral with the bearing 88. The lever is adapted to be locked in one of a number of adjusted positions to a sector 95. The particular means of locking the lever 94 on the sector may be varied. It consists, as herein shown, of a spring pressed spherical pawl 96, Figure 2, that is adapted to enter concave sockets 97, 98, 99 formed on the sector 95. The interme diate locking position, or when the spherical 1411,089 pawl 96 is engaged with the control socket 97, is a neutral position, or a position in which the motor circuit is open; and the positions represented by the sockets 98, '99 are positions in which the motor circuit is closed for operating the motor to respec tively open and close the doors.. When the lever 94 is swung to the left hand side of its neutral position to engage the spherical pawl with the socket 98, Fig ure 1, the right hand ends of the blades 74 are engaged with the split terminals 71 to close the motor circuit to operate the lat ter to open the doors, and when the lever 94 is swung to the right from the position indicated in Figure 1 to engage the spherical pawl with the socket 99, the left hand ends of the blades 74 are engaged with the split terminals 72 to close the motor circuit to operate it in a direction to close the doors. The strands or laps, 81 of the control cable are provided with turn-buckles, or other suitable take-up devices 100 for the purpose of adjustment, as will be apparent, and it will be understood that said strands are normally fixed or stationary. It will be understood that the control lever 94 may be located in any part of the build ing desired, and also that a number of such controlling devices connected to the same cable may be located in different parts of the building, so that the ope,'ating mecha nism may be controlled to open or close the doors by persons stationed at different parts of the building. In connection with the manual control of the motor circuit described, means are O vided whereby, through the cable onto. referred to, the motor circuit is automatically opened when the doors reach the limits of their travel in both their opening or closing positions. The means herein shown for ef fecting the automatic opening and closing of the doors at the limits of their opening and closing movements are associated with the arm 56 of the traveler 51 before referred to and are made as follows: The lead 81 of the controlling cable is pro vided with spaced blocks or enlargements 102,103, (Figures 1 and 6). The said arm 56 is provided with an opening through which the lead 81 of the controlling cable is threaded, as best shown in Figure. 6. The blocks or enlargements 102,103 are so spaced, longitudinally of said lead 81, that at about the time when the doors reach their closing position the arm 56 engages the block 102 to slightly shift the normally fixed cable and operate the motor switch to open the circuit and at about the time when the doors reach their full open positions the arm 56 engages the normally fixed block 103 to effect a re verse movement of the cable and switch to open the motor circuit, and the direction of the movement imparted to the operating cable through contact of said arm 56 with the respective blocks 102, 103 actuates the switch block 77 to open the motor circuit. The engagement of the spring pressed pawl 96 with the sockets of the sector 95 is such that when the cable is automatically actuated by engagement of the blocks or en largements 102, 103 with the arm 56, the pulling stress on the cable will effect rock ing movement of the manually actuated lever so as to throw it to its intermediate or neutral position. In order that the doors may be arrested at the limits of both their closing and open ing movements without throwing an over load on the motor or throwing an objection able stress on the operating mechanism, means are provided at said limits for tem porarily disconnecting the doors/from the operating mechanism, but constructed with means to afford proper operative connection

11 O between the doors and the operating mecha nism when the doors are moved towards the other direction of their travel. The means herein shown for effecting this temporary disconnection of the operating mechanism from the doors are made as fol lows: The threads of the right and left hand threaded shaft sections terminate short of the inner and outer ends of the shaft sec tions 36 to provide plain or unthreaded por tions 105 at the inner ends of said shaft sec tions and other plain, unthreaded portions 106 at the outer ends thereof (Figures 6 and 8). Surrounding the inner plain portions 105 of the shaft sections are spiral springs 107. Likewise surrounding the plain un threaded outer ends of the shaft sections are other spiral springs 108. The spiral springs 107 co-operate with discs or collars 110 that are fixed to the plain portions 105 of the shaft sections and bear against the ends of the bushings 53 of the hangers 50, 51 in which the inner plain ends of said shaft sections may rotate or the threads 36 there of may engage. The springs 108 are adapt ed to co-operate with the hangers 50, 51 and fixed abutments 111, 112 at the opposite ends of the shaft sections, the abutment 111 con stituting a part of the adjacent bracket 37, and the abutment 112 constituting a disc that is fixed to and rotates with the asso ciated shaft section 36. Said disc 112 con stitutes a part of a clutch device, the con struction and operation of which is herein after described. The operation of the safety disconnecting device is as follows:. When the doors approach the limits of 143,039 their movement in either direction, the hubs 52 of the travelers 50, 51 or their bushings, 53, engage the springs 107, 108, depending upon which direction the doors are travel ing, and place said springs under compres SO. The doors, with the travelers thus engaged with and compressing the-springs, continue to travel as long as the threads of the bushings 53 are engaged with the threads of the shaft sections 36. The parts are so proportioned that the doors reach their full closed or open positions, depending upon the direction of their travel, at the time the threads of the bushings 53 reach the ends of the threads of the shaft sections 36, and when this occurs rotation of the shaft sections 36 will impart no traveling movement to the " doors. Therefore, if the motor continues to rotate, either by its own momentum or be 'cause the switch control device has failed to operate, disconnection is effected between the door operating mechanism and the doors so that an overload is not thrown on the motor or an objectionable stress thrown on the operating mechanism. The springs 107, 108, being under com pression when the safety device is brought into service, serve to hold the screw thread ed bushings 53 against the ends of the threads of the shaft section 36, so that when said shaft sections are rotated in the oppo site directions to give traveling movement to the doors, the expansion force of said springs will serve to bring the threads of the bushings into mesh with the threads of. the shaft sections 36 and to effect a driving connection between said shaft sections and the travelers to cause the doors to move. It will be noted that the disconnection of the travelers with, and their connection to, the shaft sections is entirely automatic. So far as the broader phase of the invention is concerned, such disconnection and con nection may be otherwise effected, within the spirit and scope of the claims herein. The slip connection or clutch 61, shown best in Figures 3 and 6, is proportioned relatively to the load necessary to cause the doors to travel, that when said load is sub stantially increased, the shaft 60 will ro tate relatively to the shaft, 62 and until the load on the motor is reduced to the normal load to operate the doors, whereupon the shaft 62 will be again picked up and the doors will continue their travel. The advantage of this slipping connec stion lies in the fact that it is primarily a Safety means to avoid crushing a person or other object caught between closing doors, as well also as to avoid objectionable over load on the motor. With the construction described, it will not be necessary for the person operating the mechanism at a dis tant control station or stations to give fur ther attention to the closing or opening movements of the doors after the manually actuated lever 94 has been once thrown into position to close the motor circuit, inasmuch as the doors. will be automatically arrested when encountering an obstruction to throw an overload on the motor. As before stated, when this overload decreases to normal load, the slip or clutch connection 61 will again pick up the load and move the doors in the same direction towards which they were traveling before encountering the obstruc tion. It may at times occur that, by reason of failure of the motive power or defects in the motor, the normal or intended power cannot be transmitted to the shaft sections 36 to open and close the doors. In this event, there is provided a manually actu ated operating device which is made as fol lows: r W One of the shaft sections 36 is provided at its outer end with a sprocket wheel 115 that is loosely mounted on a bushing 116 (Figure 8) which surrounds the plain end of the associated screw shaft section. Said bushing has a flange 117 that is fixedly at TIO 15 25

12 6 1,411,089 tached to the adjacent bearing 37. The hub It will be furthermore understood that the 118 of said sprocket wheel is provided with hangers 17 and the travelers 50, 51 may also notches or recesses 118' to co-act with lugs be modified to adapt them to varying condi 119 on the disc 112, hereinbefore referred to tions of door installations. That is to say, and attached to and rotating with the shaft the construction herein shown has been de 70 section 36. The said clutch elements are vised as a preferable one for new installa normally separated by a spiral expansion tions. Where, however, the mechanism is spring 1 that is interposed between the to be applied to a door already installed, the disc 112 and the hub 118 of the sprocket hangers and travelers, as well also as the 10 wheel 115. position of the right and left hand threaded 75 The said bushing 116 is provided with a shaft, in respect of its plane relatively to the V-shaped slot 122, best shown in Figure 5. plane of the doors, may be varied. This slot is engaged by a spring pressed Referring now to the adaptation of the spherical pawl 123 that is mounted in a invention to Swinging doors, illustrated in 5 suitable socket in the hub of the sprocket Figures 9, 10, and 11, the same is made as wheel 115. An endless sprocket chain 125 follows: or other like flexible device is trained over The right and left hand screw threaded the sprocket wheel 115 so that, therethrough, shaft sections 135, their bearings, as well as the sprocket wheel may be rotated in either the operative connections of the motor 136 direction. thereto, and the motor circuit control switch 85 Normally, when the clutch elements as 137 and the distant station control device sociated with the sprocket wheel 115 and 138 are generally similar to the like features disc 112 are separated by the spring 1, illustrated in the previously described fig the spherical pawl is located at the apex e.s. 25 of the V-shaped slot 122. When, however, The doors 141,141 are supported by hinges 90 the sprocket wheel 115 is rotated in one di 142 on the jambs of the doorway. So also rection or the other, through the medium the means for manually actuating the screw of the chain 125 angular movement of the shafts, consisting of the chain or belt 139 Sprocket wheel about the axis of the bushing and sprocket 140, with its associated clutch causes said pawl to travel inwardly through devices are similar to those previously de 95 one leg of the V-shaped slot and thereby scribed. displace said sprocket wheel longitudinally The connections between the threaded of the shaft section 36 so as to engage the shaft section and the swinging doors are clutch elements in a manner to transmit made as follows: 35 relative movement of the sprocket wheel 145,145 design; links, each of which is to the right and left hand threaded pivotally connected at one end to a traveler shaft Sections. When pulling stress is re 146 that is screw threaded to engage over leased from the chain 125 the expansive the threads of its associated shaft section force of the spring 1 will separate the 135. Said links are pivotally connected at 40 clutch elements of the disc 112 and the their other ends at 147 to brackets 148 that 05 Sprocket wheel 115 and will restore the are attached to the doors near their upper pawl to the apex of the V-shaped slot 122. margins. The said travelers 146 are pre The motor 35 and the bearing bracket for vented from turning with the rotative the inner ends of the shaft sections 36 and threaded shaft sections 135 by any suitable also, for the shafts of the pinions 65, 66, interlocking connection with parts fixed 10 are herein shown, and conveniently, will be relatively to their traveling movement. As Conveniently located above also the said center parts of are the supported doorway. herein shown, the travelers are provided with extensions 150 that are apertured to On a mounting plate 1 that is fixed in receive guide rods 151 that are supported at any suitable manner to the wall 16. Said their ends by brackets 152 suitably attached 115 mounting plate 1 is so fashioned that to the wall 16. the motor 35 may be attached to either end Horizontal movement of the travelers 146, thereof, and so also that the switch base through the screw threaded shaft sections may be supported on either end of said acts through the links 145 and the brackets 5 mounting plate which is opposite to the end 148, when moving outwardly or away from 1 thereof which supports the motor. This the center of the doorway to swing the doors, arrangement affords the desirable flexibility by a pushing movement, open. Said connec to adjust the mechanism to suit different tions also act with a pulling stress, when the installation conditions. travelers move inwardly, to swing the doors 60 It will be understood, however, that in toward their closing positions. 125 stead of connecting the motor centrally of A slip connection 153 is provided between the right and left hand screw shaft sec the motor 136 and the threaded shafts. tions be conveniently 36, said motor and desirably may, in some operably instances, Also one of the travelers 146 is provided con with an arm 154 that coacts with the blocks nected to one end of the two part shaft. or enlargements 155, 155 on one of the leads 1

13 ,411, of the operating cable to automatically scribed permits the shaft 160 to be disposed open the motor circuit after it has been within the housing track structure 161 and closed through the operation of the manu permits also the manually actuated device ally actuated device 138. embracing the elements 1", 181, 182, and In the construction shown in Figures to be located inside the plane of the and 13, the right and left hand threaded wall 16. In some instances, said wall may shaft sections 160 are enclosed within the be recessed to receive a portion of the wheel track structure 161. Said track structure is 183, in which event the centers between the formed to provide a housing for said shaft. stub shaft 182 and the right and left hand sections and to provide also tracks 162 hav threaded shaft section 160 may be brought ing guard flanges 167 for the wheels 163, 163 closer together. The bearing for said shaft of the carriages for the hangers 164, is carried by a bracket 186 that may be that are connected by fittings 166 to the fixed to the track structure 161 or to the doors. The housing track structure for the wall 16. In other respects, the construction shaft sections and carriage is omitted near shown in Figures 12 and 13 is substantially the meeting line of the doors to provide space the same as the structures illustrated in the for the gearing and the bearing brackets previously described figures. therefor that connect the motor 170 to the In all of the constructions shown the door right and left hand threaded shaft sections. operating screw shaft is a multi-threaded The details of the bearings for the inner shaft, four threads being herein shown. It ends of the shaft sections, the slip joint or has been demonstrated in practice that with connection 171, and double throw switch 172, a single thread shaft of the pitch required to together with its actuating mechanism as well also as the safety stops. for the doors, may be the same as the like parts hereinbe fore described. - In the construction shown in Figures 12 and 13, the hangers 164 near the inner edges of the door carry upstanding travelers 175 also enclosed in the track housing that are threaded to engage the right and left hand threaded shaft sections 160, so that said shaft and said travelers are enclosed within the housing track structure 161. Said en closed track structure is attached to the wall 16 by means of a suitable number of straps or brackets 176. In the construction shown in said Figures 12 and 13, the operation of opening and closing the doors, in respect of the actuation thereof by the motor 170, and in respect of the operation of the safety stop devices, is the same as hereinbefore ds scribed. A traveling member 178 is attached to one of the doors and threaded over one of the leads 179 of the switch actuating cable for contact with the blocks or enlargements 1 on said lead to shift the switch to stop the doors at both limits of their movement. The modification to be observed in respect of the member 178 is that it is not attached to or carried by one of the threaded travelers, but is attached directly to and carried by one of the doors; and its shape is modified to correspond to its changed relation to the other parts. The hand actuated device for rotating the shaft 160 is also modified in the sense that the flexible hand actuated element 1' is trained over a sprocket wheel 181 that is mounted on a short stub shaft 182 and which carries a gear wheel 183 that meshes with a pinion 185 which is fixed to and rotates with one of the right and left hand threaded shaft sections 160. The construction de give the proper travel to the door the thread ed traveler, when passing from the threads of the shaft to the unthreaded sections of the shaft, move so abruptly away from the threaded portion of the shaft as to tend to injure the door supports, as the hinges in a swinging door or the hangers in a sliding door. In other words, the action of the travelers leaving the screw shafts of a single threaded shaft is a whip action, while with the multi-thread shown herein the action is smooth and without jar. The multi-thread is also advantageous inasmuch as the door cannot be opened by force applied to the door, the door becoming self locking. The multi-threaded shaft and carrier has the further advantage, when used in connec tion with the disconnecting device between the carrier and shaft, including the plain sections of the shafts and compression springs on them, in that the threads of the carrier take in to the threads of the shaft more quickly and with less abruptness than would be true with a single thread shaft. and carrier. It will, of course, be understood that my improvements may be applied to a single sliding or a single swinging door by means which will be obvious from the foregoing description, taken in connection with the drawings, and that it is not necessary to illustrate the adaptation of the operating de vice to single swinging and sliding doors... Furthermore, as before stated, the essen tial principles of the invention may be ap plied to doors or other closures which open. and close by other than horizontal move ments. Furthermore, other means may be applied to close the motor circuit at a con trol station or stations, as, for instance, a push button control, with or without relays. The invention is not intended to be limited, therefore, to the structural details shown,

14 5 O SS except as to claims wherein such details are specifically set forth and as imposed by the prior art. w m I claim as my invention: 1. A door operating mechanism compris ing, in combination, a door, a Screw shaft, reversible motor for rotating said shaft, a traveler adapted for connection to the door and threaded on said shaft, means controlled by a part which travels with the door for opening the motor circuit and for arresting the door at both limits of the door move ment, and a manually operable emergency device normally disconnected from the shaft and constructed with means to automatically connect it to and disconnect it from the said shaft to rotate the latter. 2. A door operating mechanism compris ing, in combination, a door, supporting means therefor during opening and closing movement thereof, a screw shaft, a motor to rotate the shaft in opposite directions, a traveler operatively connected to the door and threaded on said shaft, means con trolled by a part which travels with the door for opening the motor circuit and arresting the door at both limits of the door move ment, said shaft being provided at both ends with unthreaded sections over which the traveler passes comprising means at the un threaded sections of the shaft against which the traveler moves at each limit of the door movement, and a manually operated emer gency device normally disconnected from and adapted to be automatically connected to and disconnected from said shaft to oper ate the latter. 3. A door operating mechanism, in com bination, a door, Supporting means therefor during opening and closing movement, there of, a multi-threaded screw shaft, a motor to rotate the shaft in opposite directions, : multi-threaded traveler operatively con nected to the door and threaded on said shaft, means controlled by a part which travels with the door for opening the motor circuit and arresting the door at both limits of the door movement, said shaft being provided at both ends with unthreaded sections over which the traveler passes comprising com pression means at the unthreaded sections of the shaft against which the traveler moves at each limit of the door movement, and a man ually operated emergency device normally disconnected from and adapted to be auto matically connected to and disconnected compression from said shaft means to comprising operate the spiral latter, springs said which surround the unthreaded sections of the shaft and of a length to be engaged by the traveler before it leaves the multi threads of said shaft. 4. A door opening mechanism compris ing, in combination with a reversible motor, a screw shaft, operative connections be 1,411,039 tween the motor and shaft to drive the latter, a feed circuit for the motor, a double throw switch for controlling said circuit comprising a connection, embracing a normally station ary, spring-held actuating and door position indicating device having a manual control for closing the Switch, means traveling with the door and cooperating with the switch co nection for actuating said switch to open it at both limits of the door movement, and means operative at the limits of the door movement for operatively disconnecting the screw shaft from the door. 5. A door operating mechanism compris ing, in combination with a reversible motor, a Screw shaft, operative connections between the motor and shaft to drive the latter, a traveler adapted for connection to the door and threaded on said shaft, a feed circuit for the motor, a double throw switch for con trolling said circuit, means traveling with the door for operating said switch, embrac ing connections extending from said switch to a control station, with spring-held manual means at Said station acting through said connections to control said switch and to in dicate the positions of the door, and means operative at the limits of the door movement for disconnecting the motor from the door, embracing unthreaded portions of the shaft over which the traveler passes, and spring means for establishing connection between the threads of the traveler and shaft through rotation of said shaft. 6. A door operating mechanism compris ing, in combination, a reversible motor, a screw shaft, operative connections between the motor and shaft to drive the latter, oper ative connections between the door and shaft, a feed circuit for the motor, a double throw switch for controlling said circuit, embric ing an oscillating operating member and fixed terminals, a cable operatively con nected to said oscillating member, a rocking, hand actuated drum at a control station about which the cable is trained, a control ling lever therefor, spring held at its two extremes and neutral position and means carried by and movable with the door and cooperating with the cable at both limits of and shift said controlling lever to neutral position. 7. Door operating mechanism compris ing, in combination, two doors movable to ward and from each other, a right and left hand threaded shaft adapted to be rotated in opposite directions, bearings for the ends and central portion of said shaft, respec tively, travelers adapted to be connected to the doors and threaded on said shaft, and means at both ends and at the central por tion of said shaft adapted to coact with parts which travel with the doors to effect dis connection of the doors from the shaft movement of the door to open said Switch OO

15 , ,039 through one direction of rotation of the shaft and to effect connection of the shaft by a part which travels with the door for with the doors through the opposite direc stopping rotation of the shaft at both limits of the door movement, a pulley normally tion of rotation of the shaft. 8. Door operating mechanism comprising, loose on one end of said shaft, a flexible member trained over said pulley to rotate in combination, two doors movable towards the same, and a clutch for connecting, said and from each other, a right and left hand pulley to the shaft embracing co-acting threaded shaft, a reversible driving motor clutch elements fixed to the shaft and said therefor and its operating switch, bearings O pulley, the supporting member for the pulley for the ends and central portion of said being provided with a cam groove and a shaft, respectively, travelers adapted to be pawl carried by the pulley engaging said connected to the doors and threaded on said cam groove. n shaft, means at both ends and at the central 13. A door operating mechanism compris portion of said shaft adapted to coact with 5 ing, in combination with a reversible motor, parts which travel with the doors to effect a screw shaft, operative connections between disconnection of the doors from the shaft through one direction of rotation of the the motor and shaft to drive the latter, a. traveler adapted for connection to the door shaft and for effecting connection of the shaft with the doors through the opposite and threaded on said shaft, means controlled by a part which travels with the door for direction of rotation of the shaft, and means stopping rotation of the shaft at both limits traveling with one of the doors and opera tive at the opening and closing positions of of the door movement, a pulley normally. the doors for controlling the starting switch. loose on one end of said shaft, a flexible member trained over said pulley to rotate the 9. A door operating mechanism compris same, and a clutch for connecting said pull 25 ing, in combination with a reversible motor ley to the shaft embracing co-acting clutch a SCrew shaft adapted to be rotated in oppo elements fixed to the shaft and said pulley, site directions, operative connections between the supporting member for the pulley being the motor, and shaft to drive the latter, a provided with a V-shaped groove and a traveler adapted for connection to the door Spring held pawl carried by the pulley for and threaded on said shaft, and manual engagement with said groove. automatically operable means normally dis 14. The combination with a door, a rota connected from said shaft and adapted to tive shaft, operative connections between be connected to the shaft for rotating the atter, said shaft and the door to open and close the latter through rotation of the shaft, a driv A door operating mechanism compris ing member normally loose on said shaft, a ing, in combination, a reversible motor, a screw shaft adapted to be rotated in opposite flexible member trained over said driving directions, operative connections between the member to rotate the same, and means for connecting said driving member to the shaft, motor and shaft to drive the latter, a traveler operative through rotation of the driving 40 adapted for connection to the door and member. threaded on said shaft, and manually opera be means normally disconnected from said 15. The combination with a door, a screw shaft, a traveler connected to the door and shaft and adapted to be automatically con threaded to the shaft to open and close the nected to and disconnected from the shaft 45 for rotating the latter. door, a driving member normally loose on said shaft, means whereby the driving mem 11. A door operating mechanism compris ber may be rotated, and means for connect ing, in combination with a reversible motor, ing the driving member to the shaft, opera a Screw shaft, operative connections between tive through rotation of the driving member. the motor and shaft to drive the latter, a 50 traveler adapted for connection to the door 16. A door operating mechanism compris ing, in combination, a threaded operating and threaded on said shaft, means controlled by a part which travels with the door for shaft, a door hanger, a carriage therefor having rollers at the sides of the hanger, stopping rotation of the shaft at both limits laterally spaced tracks on which the said of the door movement, a pulley normally rollers travel, and a traveler extending up 55 loose on One end of said shaft, a flexible wardly from the carriage between the planes member trained over said pulley to rotate of said rollers and threaded on the shaft, the same, and a clutch for connecting said said tracks being formed on the lower mar pulley to the shaft, operative through rota tion of the pulley. gins of a housing which continues upwardly at the sides of said carriage and traveler and 12. A door operating mechanism compris around said shaft to enciose said parts. ing, in combination with a reversible motor, 17. A door operating mechanism compris a Screw shaft, operative connections between ing, in combination, a threaded operating the motor and shaft to drive the latter, a shaft, a door hanger, a carriage therefor traveler adapted for connection to the door having laterally spaced rollers, a housing and threaded on said shaft, means controlled having means to attach it to the side of a

16 O 1,411,039 door frame about the door opening, in which wardly from said carriage and threaded to said shaft is enclosed, said housing being said shaft. closed at its top and open at its bottom, and In testimony whereof I claim the forego- 10 provided at the lower margins of its side ing as my invention, I hereunto append my 5 walls with inwardly directed tracks for the signature at Chicago, Illinois, this 31st day carriage rollers, and a traveler within the of May, housing between said rollers extending up- PAUL H. LACEY.

F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, , SHEETS-SHEET 2. ssna

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

"(2.4% May 4, 1954 C. A. GUSTAFSON 2,677,202. Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet CAR. A.

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

UNITED STATES PATENT OFFICE

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Feb. 14, 1967 R. B. WENGER 3,304,094 CLIMBING WHEEL CHAIR A/C. Z. 5 is INVENTOR. a/caezo as a 7/gate, 57 d. 2. XO aoz. 1277aatavays.

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Az Z 1.357,665. Azzee/2Z27. Patented Nov. 2, y 24-cee?, A-6. vy

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 3-vi-ucvtot 21, 6)) 7/4-ee-d

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

809,643. June 9, le A. E. SMALL RAILWAY CAR DROP DOOR

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

& 9. Š. Aerary 4. Morazzzzzok. May 19, : 1,538,208. INVENTORS INTERNAL COMBUSTION MOTOR. atz Aazzzz c1. A1arclaezzf H. A. NORDWICK E. A.

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

?????????? 24,??: Aug. 12, ulazca S. CoMA/asa BY) J. S. CONNER 2,425,306. Filed April 26, 1945 INVENTOR. 2 Sheets-Sheet l

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

3,136,172. June 9, Attorneys C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS. 2 Sheets-Sheet li

June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS 3,136,172 2 Sheets-Sheet li Attorneys June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTEOARD PROPULSION UNITS 3,136,172 Filed March

June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS 3,136,172 2 Sheets-Sheet li Attorneys June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTEOARD PROPULSION UNITS 3,136,172 Filed March

United States Patent (19) Muranishi

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

s l N 2. S Aoaaaz A. u?acasow M-74a/oway, Alaata(7 & March 30, 1965 R. E. JACKSON 3,175,811 INVENTOR. A/Oaavaaaata

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005OO64994A1 (12) Patent Application Publication (10) Pub. No.: Matsumoto (43) Pub. Date: Mar. 24, 2005 (54) STATIONARY BIKE (52) U.S. Cl.... 482/8 (76) Inventor: Masaaki Matsumoto,

(19) United States US 2005OO64994A1 (12) Patent Application Publication (10) Pub. No.: Matsumoto (43) Pub. Date: Mar. 24, 2005 (54) STATIONARY BIKE (52) U.S. Cl.... 482/8 (76) Inventor: Masaaki Matsumoto,

APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

Aug. 18, H. C. H. WASH ET AL 2,051,116 POWER PRESS DRIVING MECHANISM. Zezezézy. 6.2%zz & WZ

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

Jan. 14, ,421,236. Filed June 22, E, U, MOYER ATTORNEYS LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

June 24, 1958 F. BUDRECK 2,839,965

June 24, 198 F. BUDRECK 2,839,96 COLLAPSIBLE REAR VIEW MIRROR STRUCTURE FOR - USE WITH A TRACTOR-TRAILER COMBINATION Filed Aug. 30, l9 3. Sheets-Sheet l - - Ss -------21 - - s-s 2-4 June 24, 198 F. BUDRECK

June 24, 198 F. BUDRECK 2,839,96 COLLAPSIBLE REAR VIEW MIRROR STRUCTURE FOR - USE WITH A TRACTOR-TRAILER COMBINATION Filed Aug. 30, l9 3. Sheets-Sheet l - - Ss -------21 - - s-s 2-4 June 24, 198 F. BUDRECK

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 2015 0084494A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0084494 A1 Tonthat et al. (43) Pub. Date: Mar. 26, 2015 (54) SLIDING RACK-MOUNTABLE RAILS FOR H05K 5/02 (2006.01)

(19) United States US 2015 0084494A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0084494 A1 Tonthat et al. (43) Pub. Date: Mar. 26, 2015 (54) SLIDING RACK-MOUNTABLE RAILS FOR H05K 5/02 (2006.01)

Nov. 19, 1963 W. J. LEE 3,111,246 SHIRT FOLDING MACHINE Filed May ll, Sheets-Sheet 1 INVENTOR. by A-4,5- anzawy &Arafat

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

June 6, ,987,128 W. KREG SOIL, DAMMING IMPLEMENT. Filed June ll, Sheets-Sheet. Werner Arieg INVENTOR. &&. ~~~~

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

43.4cule?o (26-12% Dec. 28, V. HAMMAR ET AL 2,103,670 WHEELED FIREARM. Z-1 ule 772 or /eta A?at 777-r. Filed Nov. 23,

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

April 22, 1969 R. R. MYERS 3,439,368 SWIMMING POOL CLEANER. Filled Jan. 3, //V/AA/7OA. aaaaya /7 a.a5. As / Al-Aza 47.4% r-77%---a A77 oawals

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

United States Patent (19)

United States Patent (19) Ogasawara et al. (54) 75 RDING LAWN MOWER Inventors: Hiroyuki Ogasawara; Nobuyuki Yamashita; Akira Minoura, all of Osaka, Japan Assignee: Kubota Corporation, Osaka, Japan Appl.

United States Patent (19) Ogasawara et al. (54) 75 RDING LAWN MOWER Inventors: Hiroyuki Ogasawara; Nobuyuki Yamashita; Akira Minoura, all of Osaka, Japan Assignee: Kubota Corporation, Osaka, Japan Appl.

2,376,968. May 29, F. M. JONES TWO-CYCLE GAS ENGINE. 2 Sheets-Sheet li. Filed Dec. 26, 1942 FIG, vucinto FREDERICK M. JONES.

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

United States Patent (19) - 11 Patent Number: 5,050,700 Kim 45) Date of Patent: Sep. 24, 1991

United States Patent (19) - 11 Patent Number: 5,050,700 Kim 45) Date of Patent: Sep. 24, 1991 54 SAFETY APPARATUS FOR ASKID-STEER 56) References Cited LOADER U.S. PATENT DOCUMENTS 2,595, i93 4/1952 Haug...

United States Patent (19) - 11 Patent Number: 5,050,700 Kim 45) Date of Patent: Sep. 24, 1991 54 SAFETY APPARATUS FOR ASKID-STEER 56) References Cited LOADER U.S. PATENT DOCUMENTS 2,595, i93 4/1952 Haug...

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

1,702,475. Feb. 19, , F. FAHNG COIL WINDING MACHINE Filed June 27, sed. 3. Sheets-Sheet 1 INVENTOR WITNESSES: 6%s/fcA.

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

June 25, 1968 ROTH 3,389,738 WINDOW SHADE APPARATUS FG. 2ASE. 4b. NVENTOR LEO ROTH. was 11- a-40, 2.11u1 2y 7. A2-2.1a-42a (arte?. ATTORNEYS.

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, SHEETS-SHEET 1. is a 12, WITVESSES. -é (?

1,229,352, C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, 1917. 3 SHEETS-SHEET 1. v NS \SS : is a 12, WITVESSES -é (?4-le-4 Szé-- 47 TORNEY. C. E. WAN NORMAN, & &S S

1,229,352, C, E, WAN NORMAN, MILLING MACHINE, APPLICATION FLED AN, 22, 190, Patented June 12, 1917. 3 SHEETS-SHEET 1. v NS \SS : is a 12, WITVESSES -é (?4-le-4 Szé-- 47 TORNEY. C. E. WAN NORMAN, & &S S

2,835,125 LATCHING MECHANISM. 3. Sheets-Sheet 2 NII N bel2. gy:jip 72UL. ali?i. 2%. s: 2. t. NU 2z, Z z? Azózzee/

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

United States Patent (19) shioka et al.

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

TVZ. SfR is. i XX. s \S3 SN. A7.3-4 Zzzez27, /z V7 724e-sezz-. 22:28. Dec. 10, 1968 B. H. PETERSEN 3,415,562 N22>SX2XXX HH C) XXXXXXX

Dec. 10, 1968 B. H. PETERSEN 3,415,56 MAGNETIC HOLD-OPEN DEVICE Filed March 15, 1967 Sheets-Sheet l Chacew 7 AMEd A We A supply C so N St KX& XXXXXXX S:X & N N>SXXXX s \S3 SN i XX HH C) :8 SfR is Narsarrin

Dec. 10, 1968 B. H. PETERSEN 3,415,56 MAGNETIC HOLD-OPEN DEVICE Filed March 15, 1967 Sheets-Sheet l Chacew 7 AMEd A We A supply C so N St KX& XXXXXXX S:X & N N>SXXXX s \S3 SN i XX HH C) :8 SfR is Narsarrin

(11) 4,398,742. United States Patent (19) Sanders. (45) Aug. 16, Assistant Examiner-Mitchell J. Hill

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0251883 A1 WANG US 2016O251883A1 (43) Pub. Date: Sep. 1, 2016 (54) LOCKING AND UNLOCKING MECHANISM FOR ADOOR LOCK (71) Applicant:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2016/0251883 A1 WANG US 2016O251883A1 (43) Pub. Date: Sep. 1, 2016 (54) LOCKING AND UNLOCKING MECHANISM FOR ADOOR LOCK (71) Applicant:

10-sea /2 72/7e/ * 22%,962a. PATENTED OCT, l0, l905, No. 801,754.

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

G, M, OGLE. CAR SEAT, APPLICATION FLED SEPT. 28, Patented Sept. 18, it : Ec/ i? 24 YN1 Y A?

G, M, OGLE. 1,240,244. CAR SEAT, APPLICATIO FLED SEPT. 28, 1915. Patented Sept. 18, 1917. M A1 c 3 SHEETS-SHEET 1. --------------------SS ---------- - - - - - - - - - - - - - - - - --- -77- : Ec/7. -------------------------

G, M, OGLE. 1,240,244. CAR SEAT, APPLICATIO FLED SEPT. 28, 1915. Patented Sept. 18, 1917. M A1 c 3 SHEETS-SHEET 1. --------------------SS ---------- - - - - - - - - - - - - - - - - --- -77- : Ec/7. -------------------------

L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, ??424,446? 3 SHEETS-SHEET?? ??? No.r. ?vvivevsbot

??424,446? L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, 1919. Patented Aug. 1, 1922. 3 SHEETS-SHEET?? No.r??? ZA 99??vvivevsbot 1,424,446. L, R, BUCKEN DALE. EPICYCLIC POWER TRANSMISSION,

??424,446? L. R. BUCKENDALE. EPICYCLIC POWER TRANSMISSION, APPCATION FLED OCT 14, 1919. Patented Aug. 1, 1922. 3 SHEETS-SHEET?? No.r??? ZA 99??vvivevsbot 1,424,446. L, R, BUCKEN DALE. EPICYCLIC POWER TRANSMISSION,

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

US 2005O25344-4A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0253444 A1 Godshaw et al. (43) Pub. Date: Nov. 17, 2005 (54) AUTOMOBILE PET BED CONSTRUCTION (22) Filed:

US 2005O25344-4A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2005/0253444 A1 Godshaw et al. (43) Pub. Date: Nov. 17, 2005 (54) AUTOMOBILE PET BED CONSTRUCTION (22) Filed:

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

United States Patent (19) Maloof

United States Patent (19) Maloof 11 Patent Number: 45) Date of Patent: Jul. 17, 1984 54 CART WITH SEAT AND STORAGE COMPARTMENT 76 Inventor: John J. Maloof, 20 Greenwood St., East Hartford, Conn. 06118

United States Patent (19) Maloof 11 Patent Number: 45) Date of Patent: Jul. 17, 1984 54 CART WITH SEAT AND STORAGE COMPARTMENT 76 Inventor: John J. Maloof, 20 Greenwood St., East Hartford, Conn. 06118

%24- # (64%ue A7 roaways. Aé26aer 7ay Aeawaz. Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

United States Patent (19)

United States Patent (19) Fujimoto (54) PROPELLING DRIVE TRANSMISSION STRUCTURE FORWALKING OPERATOR TYPE LAWN MOWER (75) Inventor: Satoshi Fujimoto, Sakai, Japan 73) Assignee: Kubota Ltd., Osaka, Japan

United States Patent (19) Fujimoto (54) PROPELLING DRIVE TRANSMISSION STRUCTURE FORWALKING OPERATOR TYPE LAWN MOWER (75) Inventor: Satoshi Fujimoto, Sakai, Japan 73) Assignee: Kubota Ltd., Osaka, Japan

June 19, 1962 v. P. DoNNER 3,039,212 HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS

June 19, 1962 v. P. DoNNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS Filed July ll, 1960. Sheets-Sheet l June 19, 1962 3,039,212 V. P. DONNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR

June 19, 1962 v. P. DoNNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR SCRAPERS Filed July ll, 1960. Sheets-Sheet l June 19, 1962 3,039,212 V. P. DONNER HYDRAULIC APRON AND EJECTOR GATE MECHANISM FOR

US A United States Patent (19) 11 Patent Number: 5,531,492 Raskevicius (45) Date of Patent: Jul. 2, 1996

IIIHIIII US005531492A United States Patent (19) 11 Patent Number: 5,531,492 Raskevicius (45) Date of Patent: Jul. 2, 1996 (54) RATCHETING LATCH MECHANISM FOR A 3,123,387 3/1964 Jackson et al.... 292/21

IIIHIIII US005531492A United States Patent (19) 11 Patent Number: 5,531,492 Raskevicius (45) Date of Patent: Jul. 2, 1996 (54) RATCHETING LATCH MECHANISM FOR A 3,123,387 3/1964 Jackson et al.... 292/21

March 27, 1956 T. A. DOURDEVILLE 2,739,366

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

United States Patent Moulton

United States Patent Moulton 54 THREE-WHEELEED ELECTRICALLY PROPELLIED CART 72) Inventor: H. Douglass Moulton, 234 Foxhurst Drive, Pittsburgh, Pa. 15238 22 Filed: June 8, 1970 21 Appl. No.: 44,185 52 U.S.C...

United States Patent Moulton 54 THREE-WHEELEED ELECTRICALLY PROPELLIED CART 72) Inventor: H. Douglass Moulton, 234 Foxhurst Drive, Pittsburgh, Pa. 15238 22 Filed: June 8, 1970 21 Appl. No.: 44,185 52 U.S.C...