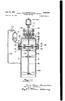

2,191,494. Feb. 27, E. F. NELSON STUD WELDER. 2 Sheets-Sheet. Filed July 5, l938 3 SSNNN. <22zz ZZZZZ 477OARAVA

|

|

|

- Sydney Watson

- 5 years ago

- Views:

Transcription

1 Feb. 27, 19. E. F. NELSN STUD WELDER Filed July, l938 2 Sheet-Sheet?Y 3 SSNNN 2 <22zz ZZZZZ 477ARAVA

2 Feb. 27, 19 E. F. NELSN STUD WELDER Filed July, Sheet-Sheet 2

3 Patented Feb. 27, 19 2 S UNITED STATES STUD WELDER 11 Claim. Thi invention relate to mechanim for elec tric welding. It i an object of the invention to provide in proved portable apparatu for electrically butt Welding Stud or other rod-like member to the Surface of metallic object. Another object of the invention i to provide, in apparatu of the cla decribed, mean for elec trically timing the preheating of the part to be joined o that all weld will be uniformly alike. A further object of the invention i to provide, in apparatu of the above-mentioned type, mean for Variably lengthening or hortening the opera tive cycle of the apparatu. The invention poee other object and fea ture of advantage ome of which, together with the foregoing, Will be pecifically et forth in the detailed decription of the invention hereunto annexed. It i to be undertood that the inven tion i not to be limited to the pecific form there f herein hown and decribed a variou other embodiment thereof may be employed within the Scope of the appended claim. 8 Referring to the drawing: Figure 1 i a vertical ectional view taken in a plane paing medially and longitudinally through one form f my tudi Welder. Figure 2 i a tranvere vertical ectional view of the tructure illutrated in Figure 1, the plane of ection being indicated by the line 2-2 of the latter figure. Figure 3 i an end elevational view of the ap paratu hown in Figure 1. A portion of the view i mitted to conerve Space in the drawing. Figure 4 i a longitudinal vertical Sectional view of a tudi welder embodying the preferred form of ny invention. The part of the mecha nim are hown in the poition that they occupy jut prior to the actual welding of a tud to the Surface of a metallic object. Figure i a tranvere vertical Sectional view of the tructure hown in Figure 4. The plane of Section i illutrated by the line - of the latter figure. Electric butt-welding of tud, or other rod-like member, to the Surface of metallic object ha long been practiced in indutry. Thi procedure ha generally been accomplihed by hand; the tud uually being held in a uitable holder which form one terminal of the welding circuit, and the other object to which the tud i to be bonded forming the other terminal. The Welder, graping the holder in hi hand, contact the charged tud and the object urface drawing the tud away from the urface o a to create an arc. PATENT FFICE Edward F. Nelon, Wallejo, Calif. Application July, 1938, Serial No. 217,34 (C ) In a hort time the metal of the object in the arc Crater and the end of the tud will have increaed in temperature to the melting point whereupon the welder quickly plunge the tud end into the arc crater, the current i turned off, and the molten metal i allowed to cool and olidify. The Stud, which i now bonded to the urface of the object, may then be eparated from the holder. There are everal undeirable feature con nected with thi hand method of welding. Firt, it i left entirely to the dicretion of the operator to determine when the repective metal of the Stud and the object to which the tud i to be bonded, have reached the proper welding tem perature. In a great many intance the metal are joined before they are in a molten tate, thereby reulting in a faulty and eaily broken Weld. Secondly, even though the metal happen to be brought to the correct temperature, the tudi may be plunged againt the object urface lightly to ne ide of the arc crater thereby alo reulting in a weld which doe not form a proper homoge neou bond between the tud and the object. In the third intance, the length of the arc gap may vary with each weld which caue the metal to heat up fater or lower a the cae may be, there by producing Weld of non-uniform trength; and, finally, but few of the tud Will be found to be truly perpendicular to the urface of the object. Thu, unle exceive clearance i al lowed in pre-drilled hole in planking or other article to be attached by the tud, coniderable difficulty will be experienced in readily fitting thee part together. Workmen encountering an inclined tud uually bring it into perpendicular poition with the aid of everal blow from a heavy hammer. Thi i a dangerou procedure ince it i likely to fracture and eriouly Weaken the weld. I have provided apparatu by mean of which all of thee defect are remedied, which will permit the placing of Stud or the like a rapidly a they have heretofore been placed by hand, and which will inure that each weld i poeed of a maximum of Strength. In detail, and referring to Figure 4 of the draw ing, the preferred form of my invention con prie a cat iron casing 6 having a plurality, preferably three, of radially extending ear each being bored to lidably receive a tubular leg 8. Each of the leg 8, at it dital end, i inter nally threaded to receive the threaded hank of a foot 9 whoe pointed end f i adapted to bear againt the urface of a metallic member 2 to which the tud 3 i to be welded. Nut 4, which clamp the lotted end of the leg 8 about the i

4 feet 9, Serve to lock the latter once they have been adjuted to a deired poition; and et crew 6 in each ear 7 erve to clamp the leg in the ear and provide for extenion and retraction of the leg a deired o that the pacing between the caing 6 and the urface of the member 2 may be varied. Mean i provided for upporting the tud 3 to be welded to the member 2 for movement per pendicularly toward and from the urface of the member. Dipoed centrally between the three paced leg 8 i a tubular chuck f, one end of which i provided with tranvere lot 8 to form a plurality of finger 9 which frictionally engage the tud 3, and the other end of which i pro vided with a threaded bore 2 for receiving the threaded Shank 22 of a cap 23. Thi connection i provided, primarily, o a to permit the mount ing of chuck adapted to Support tud of dif ferent diameter. The cap 23 i provided with a flange 24 having therein a plurality of aperture in which are inerted inulating buhing 26 through which crew 27 pa o a to attach the cap to a flange 28 formed at one end of a tubular ran 29 which i lidably mounted for axial nove ment in the end of a non-ferrou tube 3. An inulating - waher 32, interpoed between the flange 24 and 28, erve, in conjunction with the buhing 26, to electrically inulate the tud 3 from the ram. 29. Since the ran i lidable axially of the tube, the tud f3, during Such nove ment of the ram, will be moved away from and into paced relation wtih the urface of the mem ber 2. To limit thi movement of the tud o that the gap between the end thereof and the urface of the member 2 will be held at approxi mately one-fourth of an inch, a collar 33 i pro vided on the ram which impinge againt the end of the tube 3. Electro-magnetic mean i provided for effect ing movement of the ram in the tube 3. Secured in the oppoite end of the tube in any Suitable manner, uch a by mean of the pin 34, i an iron pole-piece 36 which i centrally bored to lidably journal a rod 37, the latter extending concentrically along the tube. The Irod 37, adja cent the pole-piece, i houldered and againt thi houlder abut one end of an iron armature 38 which i lidable, with the rod, in the tube 3. The oppoite end of the armature i reduced in diameter to provide an abutment 39 which may trike againt the end of a crew 4 threaded through the caing 6 and projecting into the bore of the tube 3, o a to limit movement of the armature in one direction. A waher 42, which lie againt the end of the armature, i provided on the rod, a i alo a ferrule 43 which, at one end contact the waher 42, and at the other end terminate adjacent the end of the rod, and pae lidably through an aperture formed in the end wall 44 of the ram. 29. A nut 46, threaded on the end of the rod 37, Serve to clamp the armature 38, the waher 42 and the ferrule 43 together a a unit on the rod o that all may move together with the latter. A coil pring 47 urround the ferrule and i inter poed between the end wall 44 of the ram and a flange 48 formed at the end of the ferrule adja cent the nut 46. Surrounding the end of the tube 3, in which the polepiece 36 i poitioned, i an actuating coil 49 encloed by a ferrou hell and end plate 2 and 3; and a ferrou houing 4, threaded onto the end of the tube 3f, and con tacting the pole-piece 36, erve to clamp the end plate againt the hell and the end plate 3 againt a Suitable houlder therefor provided n the caing 6. A magnetic circuit i thu pro vided, through which flux may flow when the coil 49 i excited, compriing the pole-piece 36, the houing 4, the end plate 2, the hell, the end plate 3, the caing 6, and the armature. 38. Surrounding the houing 4 i a plit leeve 6 having a pair of apertured ear 7 riing there from through which pae a bolt 8 by mean of which the leeve may be clamped, immovably, to the houing. Formed integrally with and ex tending radially from the leeve 6 i a hollow handle 9 provided with an aperture 6 in which i inerted a puhbutton witch 62, and with a tubular Spout-like projection 63. A pair of cable 64 and 66 enter the extreme end of the handle, through Suitable aperture provided therein, the former of which contain three conductor 67, a pair of which are connected with the repective terminal of the puh-button witch 62 and an other of which i connected with one end of the actuating coil 49. An additional conductor 68 connect the other end of the coil 49 with one of the terminal of the witch 62. The conductor 66 i brought out of the handle through the tubu lar projection 63, i provided with a loop 69 o a to inure ready flexing of the conductor and is Connected to a connector lug 7 which i e Cured on the Shank 22 by preure of the chuck body. The end of the handle 9 i provided With a SaW lot paing tranverely through the entrance aperture of the cable 64 and 66, and a bolt 72, which pae through apertured ear 73 formed at the end of the handle, erve to clamp the cable immovably in the handle. The normal poition of the ram 29 and the tud 3, jut prior to the welding of the tud to the Surface of the member 2, i a hown in Figure 1 wherein the end of the tud ret on the Surface of the member and the collar 33 of the ram, in Figure 4, i paced about one-fourth of an inch to the right of the end of the tube 3. After poitioning the apparatu, o that the Stud i located over the pot om the member 2 to which it i to be welded and all of the feet are reting againt the urface of the member So a to inure perpendicularity of the tud, the operator depree the puhbutton witch 62. Thi caue a flow of current through the actu ating coil 49 and imultaneouly cloe a control relay or circuit breaker on the welding current generator, not hown, which intitute a flow of current in the cable 66. Thi heavy welding current pae through the tud 3, the member 2, and back to the generator by mean of a cable, not hown, which connect the member 2 and the generator. A oon a the actuating coil 49 become energized, the flux created in the magnetic circuit thereof will attract the armature 38 toward the pole-piece 36. Thi will, through the connection between the rod 37 and the ram 29, move the ram and the tud away from the Surface of the member 2. A oon a the con tact between the end of the tud and the urface of the member 2 i broken, an arc will be truck therebetween which will rapidly raie the ten perature of the end of the tud and that area of the member in the arc crater T4 to the melting point. The ram and the Stud will, under the pull of the moving armature 38, continue to move away from the member 2 until the collar 33 of the ram impinge againt the end of the tube. 60

5 4 SS 76 3 whereupon further movement of the ram and tud will ceae. Mean i provided, operative after the arc between the tud and the member 2 ha been etablihed for an interval of time, for quickly plunging the molten end of the tud into the arc crater created in the urface of the member. Formed in the caing 6 i a rece 76 in which, and lidable along the tube 3, i a plunger 77 having thereon a flange 18 and between the flange and the bottom of the rece i interpoed a relatively heavy coil pring 79. The pring 79 tend to project the plunger outwardly from the rece toward the end of the tube 3f. Hinged, by a pivot pin 8 upported by lug 82 provided on the exterior of the caing 6, i a latch trigger 83, the pawl 84 of which engage a urface of the plunger fange 78. The latch trigger ha connected thereto, by a pivot pin 86, one end of a connecting rod 87, the other end of the latter being pivotally joined by mean of a pivot pin 88 with an end of a lever 89 which i mounted, by a pivot pin 9, on the end plate 3. A torion pring 92, engaging at it repective end the end plate 3 and the lever 89, tend to flex the articulated member, formed by the lever and the connecting rod 87, upwardly to ward the axi of the plunger. A trip lever 93, which i pivotally mounted on the caing 6 by mean of a pivot pin 94, i provided with an arm 96, which extend into the bore of the tube 3 through allined aperture 97 formed in the tube and the caing 6, and with a relatively horter arm 98 which ret on the upper ide edge of the lever 89. The arrangement of the part i Such that when one ide of the arm 96 of the trip lever 93 i in it normal poition, engaging the top therefor provided by one ide of the aperture 97, the articulated link formed by the lever 89 and the connecting rod 87 will be retrained, due to being in engagement with the end of the trip lever arm 98, from fiexing upwardly beyond a traight line paing through each of the pivot pin 86, 88 and 9. Thu the latch trigger 83 may not wing about it pivot pin 8 while the link i on dead center and conequently the trigger pawl 84, ince it engage the plunger flange 78, will maintain the plunger retracted and the pring 79 under con preion. After the arc between the tud 3 and the mem ber 2 ha been truck, a wa explained above, the ram 29 move until it contact the end of the tube 3 whereupon it top. The armature 38, however, continue to move toward the pole-piece 36, compreing the pring 47 in o doing, and advancing the waher 42 along the tube 3 toward the projecting end of the trip lever arm 96. When the waher contact the end of the arm, continued movement of the armature will caue the trip lever to wing about the axi of it pivot pin 94 thereby cauing the end of the arm, 98 to flex the articulated link downwardly. A oon a the axi of the intermediate pivot pin 88 pae ut of planar a linement with the axe of the pivot pin 86 and 9, the force exerted on the latch lever 83 by the compreed pring 79 will caue the latter lever, ince it i no longer re trained from movement by the articulated link, to wing downwardly thereby releaing the plunger and allowing the pring 79 to uddenly project the plunger and the ram 29, which i connected to the plunger by mean of a tubular extenion 99 of the plunger, toward the member 2 thereby plunging the molten end of the tud into the molten metal of arc crater 74. The perator now releae the puhbutton 62 to hut of the welding current and the current flowing in the actuating coil 49 and pull the apparatu utwardly away from the member 2 o a to trip the chuck 7 from the tud. Mean i provided for variably regulating the extent of the interval of time between etablih ment of the welding arc and the releae of the mechanim to plunge the tud into the arc crater So that the latter tep may be made to ocur exactly at the intant that the two metal to be joined have reached the correct temperature. In the houing 4 are provided a pair of parallel bore of and fo2, the former of which i ron centric with the houing axi, and a portion of the houing i hollowed out to provide a chamber 03. Aperture 4 provide communication be tween the chamber and the bore l. The bore 0 act a a dahpot cylinder and the end of the rod 3 extend thereinto to erve a a piton, while the bore 2 i provided with a piton 6 normally preed by a coil pring 7 toward one end of the bore, and i vented to the atmophere on the pring ide of the piton, by mean of a paage 08 opening into the hollow handle 9. A cap 09 i threadedly engaged with and cloe the open end of the houing 4 and a hub formed thereon ha an extenion which overlie and cloe the end of the cylinder bore f. The hub f l i axially bored and provided, within the chamber 103, with an interecting paage 2 which divide the hub bore into a pair of indi vidual portion one of which provide a bleeder opening 3 at the end of the cylinder bore of and the other of which i threaded to receive the threaded tem 4 of a needle valve 6 whoe conical point may be made, by rotating the threaded tem f4, to advance toward or recede from the pening 13. A locknut T i provided on the valve tem if 4 o that the latter may be locked in any poition to which it i adjuted. The chamber of i entirely filled with fluid, pref erably a light oil, through a uitable filler opening cloed by a crew 8, and a cover 9 i thread 4 edly engaged with the cap f 09 o a to protect the valve tem 4 againt being diturbed or damaged by accidental blow. The crew 8, which act a the filler opening plug, i extended inwardly to erve a a top for the piton o a to prevent the latter from iuing too far out of the bore 02. When the actuating coil 49 i deemergized, prior to welding a tud 13 to the member 2, the arnature 38 will ret at a remote poition with repect to the pole-piece 36 and the end of the rod 37 within the cylinder bore of will be pot tioned approximately one-fourth of an inch to the right of the left-hand ide of the opening 04 a viewed in Figure 4. Thi will allow fluid from the chamber fo3 to enter and fill the cylin der bore to through the aperture 4. A oon a the coil 49 i energized, the rod 37 will move to the left acro the opening 4. Thi will force fluid contained in the cylinder bore back 6 through the opening fo4 into the chamber 103 and, ince the travel of the end of the rod re quired to travere and cloe the opening 4 i ne-fourth of an inch, the eparation of the tud 3 and the member 2 will occur practically in tantaneouly ince no reitance to thi primary movement i offered by the fluid in the cylinder bore. From thi point on, however, con tinued movement of the rod 3 axially of the cylinder bore i reited ince the only avenue

6 of ecape for the fluid i through the retricted bleeder opening 3. The valve 6 may be et to render the area of the bleeder opening a Small or a large a deired o that the rate of pro greion of the rod or piton along the cylinder bore will be correpondingly affected. Thi gov erning of movenient of the rod 3 will, of coure, alo govern the rate of peed at which the waher 42 approache the projecting end 96 of the trip lever and a a reult the time elaping between etablihment of the welding arc and the releae of the tud to return it into the arc crater in the member f2 may be adjutably and preciely var ied. Thi time for all practical purpoe doe not exceed more than a few econd. The mov able piton 06, in the bore 02, provide for re ilient enlargement of the volume of the cham ber 03 to accommodate the fluid that i forced from the cylinder bore during advancement of the rod 37 and alo create, through the me dium of the pring?o, preure on the fluid in the chamber which ait in returning the rod 37, and the part of the apparatu connected for movement therewith to their normal poition When the actuating coil 49 i deenergized. In Figure 1, I have illutrated a modified form of apparatu, the latter being hown with the part in operative relation jut prior to making a weld. While the majority of part are func tionally identical with thoe of the preferred form of Figure 4, and bear the ame reference numeral, there are everal important difference of contruction. In the apparatu of Figure 4, a eparate ource of preferably direct current i neceary in the welding generator to excite the actuating coil 49. There are, however, everal type of welding machine which afford no cur rent other than the heavy welding current. It i to accommodate thee latter machine that I replace the actuating coil 49 with a coil con tructed of helically arranged convolution of heavy copper bar 2, one end of the coil being connected by a bu bar 22 with the welding current input lead 66 and the other end of the coil being connected by a bu bar 23 with an end of a heavy jumper lead 24, the other end of the latter being connected, a uual, with the connector lug 7 l. Thu the actuating coil i in erie with the welding circuit through the tud 3 and the member 2 and carrie the full welding current. A the time required to make a weld i very hort and a a longer interval of time i required to load another tud into the chuck and reet the mechanim, and in which the part may cool off, the heavy current paing through the coil will not caue the adjacent metallic part to become uncomfortably hot. The coil i encloed in a ferrou houing 2 formed integrally with the handle 9. The Second contructional difference i in the trip mechanim. The armature 38 i here ex tended and provided with a peripheral groove 26 having an inclined ide 27 which, a the armature move toward the left, contact and de pree a pin 28 entering the bore of the tube 3 radially through the caing 6, which pin caue flexing of the articulated link to releae the latch 83. The link i provided with the uual connecting rod 87, but the lever 89 i extended beyond the pivot pin 88 and provided with an overhanging lug 29 which ret againt the ide edge of the connecting rod 87 when the link i fully depreed to provide a top. Intead of the torion pring 92, hown in Figure 4, a coil ten ion pring 3 i provided, attached to anchor pin 32 on the lever 89 and connecting rod 8 repectively. The arrangement of the articu lated link i uch that, When in either, et or re leaed poition, the lever 89 and the connecting rod 8 will lie in angular relationhip and the axi of the pring 3 will lie in a poition offet with relation to the axi of the pivot pin 88. Thi arrangement of the pring will caue the link to Snap from one operative poition to the other. The third contructional difference i in the plunger 77. In Figure 1, the outer periphery of the plunger i provided with crew thread 33 which receive a nut 34. Thi nut may be ro tated to advance it axially of the plunger o a to compre the pring 79 and thereby provide for more forcible movement of the tud. 3 into the arc crater 4. While the greater part of the operation of the tud welder of my invention i entirely auto matic, there i one tep, other than loading addi tional tud into the chuck, and depreing the perating puhbutton, that mut be performed manually. The mechanim require "cocking' between each weld; that i, the plunger TT, after being releaed by the latch 83, mut be returned to be held by the latch before the next welding operation may be uccefully performed. Thi 'cocking' may be accomplihed, before or after an additional tud ha been inerted in the chuck, by placing the end of the chuck or tud againt a projecting object and preing the body of the Stud welder toward the object. Thi will caue the ram 29 to be moved axially whereupon it Will contact the plunger and carry the latter along with it until the flange 18 coincide with the latch 83. When thi occur, the latch pawl 84 will Snap upwardly to contact the ide of the flange, the plunger being thereafter held in thi poition until it i releaed by operation of the trip lever. claim: 1. Apparatu for welding a member forming ne electrode of an electric welding circuit to another member forming another electrode thereof, compriing mean for movably upport ing and releaably engaging one of aid elec trode, mean for moving aid one of the elec trode away from the other of aid electrode to etablih an arc gap between aid electrode, and mean perative a predetermined interval of time after etablihment of aid arc gap for re leaing aid one of the electrode from aid mov. able Supporting mean to uddenly bring aid electrode together. 2. Apparatu for welding a member forming one electrode of an electric welding circuit to another member forming another electrode there of, compriing mean for movably upporting one of aid electrode, electromagnetic mean for moving aid one of the electrode in one direction away from the other of aid electrode o a to etablih an arc gap between aid electrode, and mean operative during movement of aid one of the electrode in aid one direction and independ ent of Said electromagnetic moving mean for moving aid movable electrode in an oppoite di rection. 3. Apparatu for Welding a member forming ne electrode of an electric welding circuit to an other member forming another electrode there of, compriing axially extenible mean for mov ably upporting one of aid electrode, electro magnetic mean for moving aid one of the elec trode and it upport in one direction away from

7 3 7 the other of aid electrode to etablih an arc gap between aid electrode, and pring-preed m3an operative a preet interval of time after etablihment of aid arc gap and during con tinued movement of aid electrode upport for returning aid eparated electrode into mutual contact. 4. Apparatu for welding a member forming ne electrode of an electric welding circuit to an other member forming another electrode thereof, compriing a upport removably engaging one of aid electrode, mean on aid upport for hold ing the other of Said electrode, primary mean for moving aid electrode holding mean and the electrode held thereby away from aid firt-men tioned electrode whereby an electric arc i etab lihed between the Separated electrode, normal ly retrained econdary mean, for bringing aid electrode together after eparation thereof, and mean operative during movement of aid pri mary electrode moving mean for releaing aid retrained econdary mean for bringing Said electrode together.. Apparatu for welding a member forming one electrode of an electric welding circuit to an other member forming another electrode thereof, compriing a Support removably engaging one of Said electrode, mean on aid upport for hold ing the other of aid electrode, primary mean for moving aid electrode holding mean and the electrode held thereby away from aid firt-men tioned electrode whereby. an electric arc i e tablihed between the eparated electrode, nor mally retrained econdary mean relatively. axially movable with repect to aid primary electrode-moving mean for bringing aid elec trode together after eparation thereof, mean operative during movement of aid primary elec trode noving mean for releaing aid retrained Secondary mean for bringing aid electrode to gether, and mean for yieldably retraining move ment of Said primary moving mean. 6. Apparatu for Welding a member forming one electrode of an electric Welding circuit to an other member forming another electrode thereof, compriing a upport removably engaging one of aid electrode, mean on aid Support for hold ing the other of aid electrode, primary mean for moving aid electrode holding mean and the electrode held thereby away from aid firt-men tioned electrode whereby an electric arc i e tablihed between the Separated electrode, nor mally retrained econdary mean relatively axially movable with repect to aid primary electrode-noving mean for bringing aid elec trode together after eparation thereof, mean operative during movement of aid primary elec trode moving mean for releaing aid retrained Secondary mean for bringing aid electrode to gether, and adjutable mean for variably yield ably retraining movement of aid primary nov ing mean. 7. Apparatu for Welding a member forming one electrode of an electric welding circuit to an other member forming another electrode there of, compriing a caing, mean for removably Supporting Said caing adjacent and in paced relation to a firt of aid electrode, a ram mounted for movement in aid caing. in a direc tion away from aid firt electrode, mean on aid ran for holding a econd electrode to be moved, * upon movement of aid ram, from a poition con tacting Said firt electrode to a poition Spaced therefrom whereby an electric arc i etablihed between aid electrode, mean in aid caing Z for moving aid ram, retrained preure mean in aid caing and engaging aid ram for mov ing aid econd electrode into engagement with Said firt electrode after the etablihment of aid electric arc therebetween, and mean connected to be actuated by aid ram moving mean for releaing aid retrained preure mean. 8. Apparatu for welding a member forming ne electrode of an electric welding circuit to another member forming another electrode there of, compriing a caing, mean for removably up porting aid caing adjacent and in paced rela tion to a firt of aid electrode, a ran mounted for movement in aid caing in a direction away from Said firt electrode, mean on aid ram for holding a econd electrode to be moved, upon movement of Said ram, from a poition contact ing aid firt electrode to a poition paced there from whereby an electric arc i etablihed be tween aid electrode, element providing a mag netic circuit including an armature connected and movable with aid ram, mean for creating magnetic flux in aid magnetic circuit to move Said armature and ram, a plunger adjacent aid ran and movable in a direction counter to the direction of movement of aid ram, aid plunger being operatively connected to aid ram to impart Counter movement to the latter, preure mean for moving aid plunger, releaable mean for holding Said plunger againt movement, and mean engageable by and during movement of Said armature for releaing aid plunger holding e.s. 9. Apparatu for welding a member forming one electrode of an electric welding circuit to another member forming another electrode there of, compriing a caing, mean for removably Supporting aid caing adjacent and in paced relation to a firt of aid electrode, a ram mounted for movement in aid caing in a direc tion away from Said firt electrode, mean on aid ram for holding a econd electrode to be moved, upon movement of aid ram, from a poition con tacting aid firt electrode to a poition paced therefrom whereby an electric arc i etablihed between aid electrode, element providing a magnetic circuit including an armature connected and movable with aid ram, mean for creating magnetic flux in aid magnetic circuit to move aid armature and ram, a plunger adjacent aid ram and movable in a direction counter to the direction of movement of Said ram, aid plunger being operatively connected to Said ram to im part counter movement to the latter, a com preible pring interpoed between aid caing and aid plunger for moving the latter, a relea able latch on aid caing and engaging aid plunger for maintaining aid pring in compre ion, and mechanim including a trip lever opera tively connected with aid latch, aid trip lever being dipoed in the path of movement of aid arnature whereby the movement of aid arma ture may releae aid latch. ka 10. apparatu for welding a member forming one electrode of an electric Welding circuit to an other member forming another electrode thereof, compriing a caing, mean for removably up porting aid caing adjacent and in paced rela tion to a firt of aid electrode, a ram mounted for movement in aid caing in a direction away from aid firt electrode, mean on aid ram for holding a econd electrode to be moved, upon movement of aid ram, from a poition contact ing aid firt electrode to a poition paced there from - whereby an electric arc i etablihed be

8 6 tween aid electrode, element providing a mag netic circuit including an armature Connected and movable with aid ram, mean for creating magnetic flux in aid magnetic circuit to move aid armature and ram, a plunger adjacent aid ram and movable in a direction counter to the direction of movement of aid ram, Said plunger being operatively connected to Said ram to im part counter movement to the latter, preure mean for moving aid plunger, releaable mean for holding aid plunger againt movement, mean engageable by and during movement of aid armature for releaing aid plunger holding mean, a houing fixed to aid caing, aid hou ing having a bore therein provided with a vent aperture, a rod Secured to Said armature and lidably entering aid houing bore, mean for admitting fluid into aid houing bore to be forced through aid vent aperture upon move ment of aid rod in aid bore by aid armature, and mean for variably obtructing paage of aid fluid through aid. Vent aperture. 11. Apparatu for Welding a member forming ne electrode of an electric welding circuit to another member forming another electrode thereof, compriing a caing, mean for remova bly Supporting Said caing adjacent and in paced relation to a firt of aid electrode, a ram mounted for movement in Said caing in a direc tion away from aid firt electrode, mean on aid ram for holding a econd electrode to be moved, upon movement of Said ram, from a poition contacting aid firt electrode to a poition paced therefrom whereby an electric arc i etablihed between aid electrode, element providing a magnetic circuit including an armature connected and movable with aid ram, mean for creating magnetic flux in aid magnetic circuit to move aid armature and ram, a plunger adjacent aid ram and movable in a direction counter to the direction of movement of aid ram, aid plunger being peratively connected to Said ram to im part counter movement to the latter, preure mean for moving aid plunger, releaable mean for holding aid plunger againt movement, mean engageable by and during movement of aid armature for releaing aid plunger hold ing mean, a houing fixed to aid caing, aid houing having firt and econd bore therein, a chamber for containing fluid and port provid ing communication between aid chamber and Said firt bore, a cover on aid houing having an extended portion cloing aid firt bore and hav ing therein an opening to provide a vent for aid firt bore, a rod, Secured to and movable with aid armature, lidably entering aid firt bore, the end of aid rod having it normal poition of ret beyond aid port and aid vent opening of aid firt bore whereby aid port are uncov ered to admit fluid from aid chamber into aid firt bore, aid rod upon being moved along aid firt bore, by Said armature, forcing fluid con tained in aid latter bore through aid vent open ing into Said chamber, a valve in aid houing cover for variably obtructing aid vent opening, and a pring reited piton in and movable axial ly of Said econd bore a fluid i forced into aid chamber from aid firt bore. EDWARDF.NELSN

fore, United States Patent to GS ES (45) Apr. 26, Mr V (11) 4,019,360 shaft and the rolling stand drive shafts are equal in their

United State Patent to Biernot et al. 4 WIRE ROD ROLLING MILL 76) Inventor: Okar Biermot, Enheimer Str. 48; Albert Bier, Am Kloterhang 1, both of St. Ingbert, Germany, 6670 22 Filed: Sept. 22, 197 (21)

United State Patent to Biernot et al. 4 WIRE ROD ROLLING MILL 76) Inventor: Okar Biermot, Enheimer Str. 48; Albert Bier, Am Kloterhang 1, both of St. Ingbert, Germany, 6670 22 Filed: Sept. 22, 197 (21)

April 2, N. R. POST ET AL 2,195,631 PLOW . M26%/W 2 A A3 a. A257 INVENTOR5. x7-rás ATTORNEYS.

April 2, 1940. N. R. POST ET AL 2,19,631 Filed July 31, 1937 3. Sheet-Sheet l Sl K. t K. M26%/W 2 A.267 262A3 a. A27 INVENTOR S. BY x7-rá 7 ATTORNEYS. April 2, 1940. N. R. POST ET AL 2,19,631 Fillied July

April 2, 1940. N. R. POST ET AL 2,19,631 Filed July 31, 1937 3. Sheet-Sheet l Sl K. t K. M26%/W 2 A.267 262A3 a. A27 INVENTOR S. BY x7-rá 7 ATTORNEYS. April 2, 1940. N. R. POST ET AL 2,19,631 Fillied July

USOOS239155A. United States Patent (19) 11 Patent Number: 5,239,155 Olsson (45) Date of Patent: Aug. 24, 1993

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United State US 2011 0005694A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0005694 A1 NG (43) Pub. Date: Jan. 13, 2011 (54) ADJUSTABLE SPRING ASSIST FOR WINDOW (52) U.S. Cl.... 160/311;

(19) United State US 2011 0005694A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0005694 A1 NG (43) Pub. Date: Jan. 13, 2011 (54) ADJUSTABLE SPRING ASSIST FOR WINDOW (52) U.S. Cl.... 160/311;

(12) United States Patent (10) Patent No.: US 6,418,722 B1. Arnold (45) Date of Patent: Jul. 16, 2002

USOO6418722B1 (12) United State Patent (10) Patent o.: Arnold (45) Date of Patent: Jul. 16, 2002 (54) TURBOCHARGER BEARIG SYSTEM 4.322,949 A * 4/1982 Byrne et al.... 60/606 4,420,160 A 12/1983 Laham...

USOO6418722B1 (12) United State Patent (10) Patent o.: Arnold (45) Date of Patent: Jul. 16, 2002 (54) TURBOCHARGER BEARIG SYSTEM 4.322,949 A * 4/1982 Byrne et al.... 60/606 4,420,160 A 12/1983 Laham...

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

UNITED STATES PATENT OFFICE

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Nov. 19, 1963 W. J. LEE 3,111,246 SHIRT FOLDING MACHINE Filed May ll, Sheets-Sheet 1 INVENTOR. by A-4,5- anzawy &Arafat

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

TVZ. SfR is. i XX. s \S3 SN. A7.3-4 Zzzez27, /z V7 724e-sezz-. 22:28. Dec. 10, 1968 B. H. PETERSEN 3,415,562 N22>SX2XXX HH C) XXXXXXX

Dec. 10, 1968 B. H. PETERSEN 3,415,56 MAGNETIC HOLD-OPEN DEVICE Filed March 15, 1967 Sheets-Sheet l Chacew 7 AMEd A We A supply C so N St KX& XXXXXXX S:X & N N>SXXXX s \S3 SN i XX HH C) :8 SfR is Narsarrin

Dec. 10, 1968 B. H. PETERSEN 3,415,56 MAGNETIC HOLD-OPEN DEVICE Filed March 15, 1967 Sheets-Sheet l Chacew 7 AMEd A We A supply C so N St KX& XXXXXXX S:X & N N>SXXXX s \S3 SN i XX HH C) :8 SfR is Narsarrin

April 5, G, E, SWANSON 2,113,007 CYLINDER LOCK. NS: S.S.S.S.S Né EEE SS W. a. <SNSSSSSSSS/fde. is E( 4 NN. p7 NSN NNNN N&zo 76 v7 /6 2/23 / NS

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 8, 1950 C. TREE 2,517,738 TAPER BORING HEAD Z72O H-2 4% Eazy 8XXX SSNESNS N NS 3. 2 S. V2 A. SE% AS/ N NVENTOR CHARLES TREE

Aug. 8, 1950 C. TREE 2,517,738 TAPER BORIG HEAD Filed May 26, 1947 2 Sheet-Sheet 127.7 Z72O.2 42. 29. H-2 4% Eazy 3 XY) w. XXXX zzz!ii-ii a/ 'w R 8XXX SSESS 43 8XXX SSXXXXXX ) S 32 % S é 3. 2 S. V2 A..

Aug. 8, 1950 C. TREE 2,517,738 TAPER BORIG HEAD Filed May 26, 1947 2 Sheet-Sheet 127.7 Z72O.2 42. 29. H-2 4% Eazy 3 XY) w. XXXX zzz!ii-ii a/ 'w R 8XXX SSESS 43 8XXX SSXXXXXX ) S 32 % S é 3. 2 S. V2 A..

"(2.4% May 4, 1954 C. A. GUSTAFSON 2,677,202. Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet CAR. A.

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

Six R. Seizi. United States Patent 19 ZKK, 2.S. NSS NEG. Sayo et al. 11 4,150, Apr. 24, ELECTROMAGNETIC CLUTCH NS3NS

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

1,856, f6%zz/6/6474.2% Z7.Z274/z ZA/2Zays/2a2272. Patented Oct. 26, SHITLE veza vo z. STEERING MECHANISM FOR TRACTORS, III

1,856,680. E, E, WCKERSHAM, STEERING MECHANISM FOR TRACTORS, APPLICATION FILED OCT, 17, 1918, Patented Oct. 6, 190. SHEETS-S HEET 1. 1 $. S a H. 3. t. EIIR. I. SHITLE % It fi i Semafi 77 veza vo z. Z7.Z74/z

1,856,680. E, E, WCKERSHAM, STEERING MECHANISM FOR TRACTORS, APPLICATION FILED OCT, 17, 1918, Patented Oct. 6, 190. SHEETS-S HEET 1. 1 $. S a H. 3. t. EIIR. I. SHITLE % It fi i Semafi 77 veza vo z. Z7.Z74/z

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

United States Patent (19) shioka et al.

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 14, 1967 R. B. WENGER 3,304,094 CLIMBING WHEEL CHAIR A/C. Z. 5 is INVENTOR. a/caezo as a 7/gate, 57 d. 2. XO aoz. 1277aatavays.

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

June 25, D. HEYER 2,205,975 VENTILATED WARIABLE. SPEED POWER UNIT. rose asses es 2 2 %2N S62 23 NSN. e %&rar s. is ed.

June 2, 19. D. HEYER 2,,97 VENTILATED WARIABLE. SPEED PWER UNIT Filed Feb. 19, 1934 Sheet-Sheet Z2 roe ae e 2 2 %2N S62 23 EE 2 YS33. E II Sy - E-43 AY 2 al NSNS 2 X Yw e %&rar EI, g3 er NSN S243.%; 2126

June 2, 19. D. HEYER 2,,97 VENTILATED WARIABLE. SPEED PWER UNIT Filed Feb. 19, 1934 Sheet-Sheet Z2 roe ae e 2 2 %2N S62 23 EE 2 YS33. E II Sy - E-43 AY 2 al NSNS 2 X Yw e %&rar EI, g3 er NSN S243.%; 2126

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

uranayasa NNN (226er? Z /zcz-az77a 7-z Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING ZZZZZZZZA SSXSSSSSSSSSSS 50 \... "...

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United tates (12) Patent Application Publication (10) Pub. No.: U 2010/00593.05 A1 Osorn et al. U 201000593 05A1 (43) Pub. Date: Mar. 11, 2010 (54) (75) (73) (21) (22) PLT CHANCAE WITH FIXED AXLE

(19) United tates (12) Patent Application Publication (10) Pub. No.: U 2010/00593.05 A1 Osorn et al. U 201000593 05A1 (43) Pub. Date: Mar. 11, 2010 (54) (75) (73) (21) (22) PLT CHANCAE WITH FIXED AXLE

Q/% fajwzl/y/f. a. a; %M f. Patented Get. 23, SHEETS SHEET I. awvwalto'a. W. S. Tall/WEE.v CIRCUIT BREAKER. Zé ~~

W. S. Tall/WEE.v CIRCUIT BREAKER. APPLICATION FILED sumac, x915. Patented Get. 23, 1917. 2 SHEETS SHEET I. Zé ~~ w'kmeobeo v Q/% fajwzl/y/f. a. a; %M f awvwalto'a W. S. MAYER. CIRCUIT BREAKER. APPLICATION

W. S. Tall/WEE.v CIRCUIT BREAKER. APPLICATION FILED sumac, x915. Patented Get. 23, 1917. 2 SHEETS SHEET I. Zé ~~ w'kmeobeo v Q/% fajwzl/y/f. a. a; %M f awvwalto'a W. S. MAYER. CIRCUIT BREAKER. APPLICATION

United States Patent (19) Belter

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

TC-200 Series. Application. Features. Applicable Literature. Single Bulb Thermostats General Instructions

T-200 Serie Single ulb Thermotat General Intruction Application Thee unit are ued for on-off control of media temperature in duct, tank, etc. Feature Mechanim encloed in rugged die cat cae with metal cover.

T-200 Serie Single ulb Thermotat General Intruction Application Thee unit are ued for on-off control of media temperature in duct, tank, etc. Feature Mechanim encloed in rugged die cat cae with metal cover.

June 6, ,987,128 W. KREG SOIL, DAMMING IMPLEMENT. Filed June ll, Sheets-Sheet. Werner Arieg INVENTOR. &&. ~~~~

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

Az Z 1.357,665. Azzee/2Z27. Patented Nov. 2, y 24-cee?, A-6. vy

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

May 19, 1964 AT TORNEY 3,133,451. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT. Filed Dec. 28, 196l. 3. Sheets-Sheet 1 R CHARD J.

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

(12) Patent Application Publication (10) Pub. No.: US 2013/ A1

(19) United State (12) Patent Application Publication (10) Pub. No.: US 2013/0134109 A1 TWeit et al. US 2013 0134109A1 (43) Pub. Date: (54) (75) (73) (21) (22) SETTLING VESSEL AND METHOD OF USE Inventor:

(19) United State (12) Patent Application Publication (10) Pub. No.: US 2013/0134109 A1 TWeit et al. US 2013 0134109A1 (43) Pub. Date: (54) (75) (73) (21) (22) SETTLING VESSEL AND METHOD OF USE Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140299792A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0299792 A1 Yee et al. (43) Pub. Date: Oct. 9, 2014 (54) SEALING ABOUT A QUARTZ TUBE (52) U.S. Cl. CPC... F2IV31/005

(19) United States US 20140299792A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0299792 A1 Yee et al. (43) Pub. Date: Oct. 9, 2014 (54) SEALING ABOUT A QUARTZ TUBE (52) U.S. Cl. CPC... F2IV31/005

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

Aug. 18, H. C. H. WASH ET AL 2,051,116 POWER PRESS DRIVING MECHANISM. Zezezézy. 6.2%zz & WZ

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

Aug. 18, 1936. H. C. H. WASH ET AL 2,051,116 Filed Jan. 22, 1934 2. Sheets-Sheet l Zezezézy. % 6.2%zz & WZ Aug. 18, 1936. H. C. H. WALSH ET AL Filed Jan. 22, 1934 2,051,116 2 Sheets-Sheet 2 62/64% WZ 64%,

2 121,002. June 21, R. C. BAKER CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet l ATTORNEY

June 21, 1938. 2 121,002 R. C. BAKER CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet l BY ATTORNEY June 21, 1938. R. C. EBAKER 2,121,002 CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS

June 21, 1938. 2 121,002 R. C. BAKER CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet l BY ATTORNEY June 21, 1938. R. C. EBAKER 2,121,002 CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS

2,835,125 LATCHING MECHANISM. 3. Sheets-Sheet 2 NII N bel2. gy:jip 72UL. ali?i. 2%. s: 2. t. NU 2z, Z z? Azózzee/

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

s /5 June 12, 1951 H. E. SPEARS ET AL 2,556,854 7 ZN NSN MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE Filed Oct 29, Saeets-Sheet 1

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

5:52, yz/ 2S o. (12) Patent Application Publication (10) Pub. No.: US 2004/ A1. (19) United States

(19) United States US 20040204282A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0204282 A1 Green et al. (43) Pub. Date: Oct. 14, 2004 (54) INTER-AXLE DIFFERENTIAL LOCK SHIFT MECHANISM (76)

(19) United States US 20040204282A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0204282 A1 Green et al. (43) Pub. Date: Oct. 14, 2004 (54) INTER-AXLE DIFFERENTIAL LOCK SHIFT MECHANISM (76)

McDonald (45) Date of Patent: Oct. 7, (54) LITHIUM ION BATTERY COOLING SYSTEM (56) References Cited

(12) United tate Patent U008852772B2 (10) Patent No.: U 8,852,772 B2 McDonald (45) Date of Patent: Oct. 7, 2014 (54) LITHIUM ION BATTERY COOLING YTEM (56) Reference Cited COMPRIING DELECTRICFLUID U.. PATENT

(12) United tate Patent U008852772B2 (10) Patent No.: U 8,852,772 B2 McDonald (45) Date of Patent: Oct. 7, 2014 (54) LITHIUM ION BATTERY COOLING YTEM (56) Reference Cited COMPRIING DELECTRICFLUID U.. PATENT

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

Jan. 23, O. A. KEHE 2,367,682 LANDING GEAR BY-PASS WALVE. a N SS SS N NS SS M6 SS M9 O NSN y I 2 N 6. DESV at. at 2.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

United States Patent (19) Kline et al.

United States Patent (19) Kline et al. 11 Patent Number: 45 Date of Patent: Jul. 3, 1990 54 BRAKING SYSTEMAND BREAK-AWAY BRAKNG SYSTEM 76 Inventors: Wayne K. Kline, R.D. 1, Box 340, Turbotville, Pa. 17772;

United States Patent (19) Kline et al. 11 Patent Number: 45 Date of Patent: Jul. 3, 1990 54 BRAKING SYSTEMAND BREAK-AWAY BRAKNG SYSTEM 76 Inventors: Wayne K. Kline, R.D. 1, Box 340, Turbotville, Pa. 17772;

EWSAN. United States Patent (19) 4,696,524. Cloyd. Sep. 29, ROBOT ARM COUPLING APPARATUS Inventor: Assignees:

United States Patent (19) Cloyd (54) (75) (73) 21) 22 51) (52) (58) (56) ROBOT ARM COUPLING APPARATUS Inventor: Assignees: William C. Cloyd, Lexington, Ky. Custom Tool & Mfg. Co.; Automation Development

United States Patent (19) Cloyd (54) (75) (73) 21) 22 51) (52) (58) (56) ROBOT ARM COUPLING APPARATUS Inventor: Assignees: William C. Cloyd, Lexington, Ky. Custom Tool & Mfg. Co.; Automation Development

2,376,968. May 29, F. M. JONES TWO-CYCLE GAS ENGINE. 2 Sheets-Sheet li. Filed Dec. 26, 1942 FIG, vucinto FREDERICK M. JONES.

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

Jan. 19, P. E. Johnson 1,842,100

Jan. 19, 1932. P. E. Johnson THERAPEUTIC LAMP Filed Aug. 19, 1927 3 Sheets-Sheet l 2 reefs seen ES Jan. 19, 1932. P. E. JOHNSON THERAPEUTIC AMP Filed Aug. 19, 1927 3. Sheets-Sheet 2 Jan. 19, 1932. P. e.

Jan. 19, 1932. P. E. Johnson THERAPEUTIC LAMP Filed Aug. 19, 1927 3 Sheets-Sheet l 2 reefs seen ES Jan. 19, 1932. P. E. JOHNSON THERAPEUTIC AMP Filed Aug. 19, 1927 3. Sheets-Sheet 2 Jan. 19, 1932. P. e.

WAMI ENSI eae, EsNetII E A2. 2.Er. a ( A2 HEAE M - 15 / a7. Ells.S. 7 a M8 7 Ž22/ A. A. MEDDOCK 27 BY SWAZZZZ

Nov. 24, 1953 A. A. MEDDOCK AUTOMATIC QUICK DISCONNECT COUPLING Filed Dec. 28, 1948 m 2 Sheets-Sheet M - 15 /7 #3 2.Er. HEAE SWAZZZZ Fiil, WAMI FM if EsNetII 44 MA v 26 387 a7 a 26-47 (72.247 A2 7 a ENSI

Nov. 24, 1953 A. A. MEDDOCK AUTOMATIC QUICK DISCONNECT COUPLING Filed Dec. 28, 1948 m 2 Sheets-Sheet M - 15 /7 #3 2.Er. HEAE SWAZZZZ Fiil, WAMI FM if EsNetII 44 MA v 26 387 a7 a 26-47 (72.247 A2 7 a ENSI

1,702,475. Feb. 19, , F. FAHNG COIL WINDING MACHINE Filed June 27, sed. 3. Sheets-Sheet 1 INVENTOR WITNESSES: 6%s/fcA.

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

No.sse,*****<<<<<<<<<<<<

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

Sept. 20, 1971 L, A, CHESHER 3,606,112 RETRACTABLE BEVERAGE HOLDER FOR MOTOR WEHICLES. "Ne ) h \ 23. es/fs-s. Fig. 2 E3 2 (2S, Si. N.

Sept. 20, 1971 L, A, CHESHER Filed Jan. 28, 1970 3 Sheets-Sheet Hi (1. s A. 2 Wrze "Ne ) h \ 23 3f he W \, SC-3/ es/fs-s 32 33 Fig. 7 3? Y62 - - a 2 E3 2 (2S, Si Y N. aa 24 - - - - - -9 1-- //W/EW7OA Leonord

Sept. 20, 1971 L, A, CHESHER Filed Jan. 28, 1970 3 Sheets-Sheet Hi (1. s A. 2 Wrze "Ne ) h \ 23 3f he W \, SC-3/ es/fs-s 32 33 Fig. 7 3? Y62 - - a 2 E3 2 (2S, Si Y N. aa 24 - - - - - -9 1-- //W/EW7OA Leonord

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 2012O181130A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0181130 A1 Fukunaga (43) Pub. Date: Jul.19, 2012 (54) TORQUE CONVERTER Publication Classification 51) Int.

(19) United States US 2012O181130A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0181130 A1 Fukunaga (43) Pub. Date: Jul.19, 2012 (54) TORQUE CONVERTER Publication Classification 51) Int.

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

22-y 2 24, 7. -l- az. Z é - Jan. 26, 1971 D. F. webster 3,557,549 TURBOCHARGER SYSTEM FOR INTERNAL COMBUSTION ENGINE. is is a ST.

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

IIII. United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998

IIII USOO5775234A United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998 54) HEIGHT ADJUSTABLE OVERBED TABLE FOREIGN PATENT DOCUMENTS AND LOCKING DEVICE THEREFOR

IIII USOO5775234A United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998 54) HEIGHT ADJUSTABLE OVERBED TABLE FOREIGN PATENT DOCUMENTS AND LOCKING DEVICE THEREFOR

26, 5.3% gence Scott,

April 25, 1967 R. J. RADUS ETAL 3,316,514 FAIL SAFE ELECTRO-MAGNETIC LIFTING DEVICE WITH SAFETY-STOP MEANS Filed March 29, 1965 WITNESSES: F.G. 3. FG. 4. F.G. 5. NVENTORS 26, 5.3% gence Scott, 3-2%y Raymond

April 25, 1967 R. J. RADUS ETAL 3,316,514 FAIL SAFE ELECTRO-MAGNETIC LIFTING DEVICE WITH SAFETY-STOP MEANS Filed March 29, 1965 WITNESSES: F.G. 3. FG. 4. F.G. 5. NVENTORS 26, 5.3% gence Scott, 3-2%y Raymond

United States Patent (19) Priede

United States Patent (19) Priede 11 Patent Number: Date of Patent: Feb. 2, 1988 54 CLOCKSPRING INTERCONNECTOR 75 Inventor: Lorenz H. Priede, Valparaiso, Ind. 73 Assignee: Method Electronics, Inc., Chicago,

United States Patent (19) Priede 11 Patent Number: Date of Patent: Feb. 2, 1988 54 CLOCKSPRING INTERCONNECTOR 75 Inventor: Lorenz H. Priede, Valparaiso, Ind. 73 Assignee: Method Electronics, Inc., Chicago,

Zy <a (6- S32 %24 rx 2 -- EE N7 EEa WEF ase2/zes 4. Zafayer & WA 2-6-, &B 467. ZO s e \\\ Ec

June, 1933. S. A. DAAGER POWER TAKE-OFF Filed Dec. 31, 1931 2 Sheets-Sheet l ZO 7. 227 6. & WA 2-6-, Z S32 %24 rx 2 -- EE N7 EEa 26. - s e \\\ Ec M N EA ty. title WEF - 27.47 2. ase2/zes 4. Zafayer Zy

June, 1933. S. A. DAAGER POWER TAKE-OFF Filed Dec. 31, 1931 2 Sheets-Sheet l ZO 7. 227 6. & WA 2-6-, Z S32 %24 rx 2 -- EE N7 EEa 26. - s e \\\ Ec M N EA ty. title WEF - 27.47 2. ase2/zes 4. Zafayer Zy

-10 III. United States Patent to. 39a. 39b. 21 Claims, 3 Drawing Sheets. Appl. No.: 643,492 Fied: May 6, 1996 Int. Cla.m.

United States Patent to Lutzker III US005683166A 11 Patent Number: 5,683,166 45 Date of Patent: Nov. 4, 1997 54 (76 21 22) 51 52 (58) ELECTROLUMNESCENT WALLPLATE Inventor: Robert S. Lutzker, Woodstone

United States Patent to Lutzker III US005683166A 11 Patent Number: 5,683,166 45 Date of Patent: Nov. 4, 1997 54 (76 21 22) 51 52 (58) ELECTROLUMNESCENT WALLPLATE Inventor: Robert S. Lutzker, Woodstone

(11) 4,398,742. United States Patent (19) Sanders. (45) Aug. 16, Assistant Examiner-Mitchell J. Hill

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

United States Patent (19) 11 Patent Number: 5,295,304

O H USOO5295304A United States Patent (19) 11 Patent Number: 5,295,304 Ashley, Jr. 45) Date of Patent: Mar. 22, 1994 (54) METHOD FOR PRODUCING A FULL FACE Primary Examiner-P. W. Echols FABRICATED WHEEL

O H USOO5295304A United States Patent (19) 11 Patent Number: 5,295,304 Ashley, Jr. 45) Date of Patent: Mar. 22, 1994 (54) METHOD FOR PRODUCING A FULL FACE Primary Examiner-P. W. Echols FABRICATED WHEEL

United States Patent (19) Cronk et al.

United States Patent (19) Cronk et al. (S4) LANDING GEAR FOR ULTRALIGHT AIRCRAFT 76) Inventors: David Cronk, 1069 Eucalyptus Ave., Vista, Calif. 92025; Lyle M. Byrum, 1471 Calle Redonda, Escondido, Calif.

United States Patent (19) Cronk et al. (S4) LANDING GEAR FOR ULTRALIGHT AIRCRAFT 76) Inventors: David Cronk, 1069 Eucalyptus Ave., Vista, Calif. 92025; Lyle M. Byrum, 1471 Calle Redonda, Escondido, Calif.

(12) United States Patent (10) Patent No.: US 6,706,990 B1

USOO6706990B1 (12) United States Patent (10) Patent No.: Olsson () Date of Patent: Mar. 16, 2004 (54) RESISTANCE WELDER MULTI-PURPOSE 2,130,657 A * 9/1938 Watkin... 219/86. ATTACHMENT 2,2,009 A * 10/1948

USOO6706990B1 (12) United States Patent (10) Patent No.: Olsson () Date of Patent: Mar. 16, 2004 (54) RESISTANCE WELDER MULTI-PURPOSE 2,130,657 A * 9/1938 Watkin... 219/86. ATTACHMENT 2,2,009 A * 10/1948

Dec. 5, L. M., TAYLOR - 2,364,109. 8% Né C. INVENTOR. A Zo Yao /7, 74Yao e ATTORNEY.

Dec. 5, 1944. L. M., TAYLOR - Filed May 5, 1941 2 Sheets-Sheet NZ % 8% Né C INVENTOR. A Zo Yao /7, 74Yao e ATTORNEY. m Dec. 5, 1944. L. M. TAYLOR CRANKSHAFT AND METHOD FOR MAKING THE SAME Filed May 5,

Dec. 5, 1944. L. M., TAYLOR - Filed May 5, 1941 2 Sheets-Sheet NZ % 8% Né C INVENTOR. A Zo Yao /7, 74Yao e ATTORNEY. m Dec. 5, 1944. L. M. TAYLOR CRANKSHAFT AND METHOD FOR MAKING THE SAME Filed May 5,

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

May 7, ,199,501. J. MacBLANE SAFETY DEVICE FOR PUNCH PRESSES. Filed May 24, Sheets-Sheet INVENTOR. utarres?eat

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

April 2, 1968 O. BE TRAM 3,375,595 SINGLE BUCKET EXCAVATOR 12 INVENTOR. OS M A NO BE L T R A N. "I'llur awl ov. 4-wa

April 2, 1968 O. BE TRAM SINGLE BUCKET EXCAVATOR Filed April 27, 1965 2. Sheets-Sheet 12 INVENTOR. OS M A NO BE L T R A N "I'llur awl ov 4-wa April 2, 1968 O. BELTRAM SINGLE EUCKET EXCAVATOR Filed April

April 2, 1968 O. BE TRAM SINGLE BUCKET EXCAVATOR Filed April 27, 1965 2. Sheets-Sheet 12 INVENTOR. OS M A NO BE L T R A N "I'llur awl ov 4-wa April 2, 1968 O. BELTRAM SINGLE EUCKET EXCAVATOR Filed April

issue? - $4.4% Vils/lor (Zigsten July 9, 1957 Nils-Olof OLESTEN 2,798,743 FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED

July 9, 1957 Nils-Olof OLESTEN FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED AIRCRAFT TO GROUND MOUNTED SILENCERS Filed March 23, 1955 3 Sheets-Sheet l $4.4% Vils/lor (Zigsten issue? - : July

July 9, 1957 Nils-Olof OLESTEN FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED AIRCRAFT TO GROUND MOUNTED SILENCERS Filed March 23, 1955 3 Sheets-Sheet l $4.4% Vils/lor (Zigsten issue? - : July

ELECTROMAGNETIC SINGLE-DISC CLUTCHES

ELECTROMAGNETIC SINGLE-DISC CLUTCHES Type EBA & EBK EBA EBK Catalogue No. : V/C/14/01 Optional On Requet 01 02 03 04 05 06 07 Part No Decription 01 Rivet 02 Spring plate 03 Armature plate 04 Friction plate

ELECTROMAGNETIC SINGLE-DISC CLUTCHES Type EBA & EBK EBA EBK Catalogue No. : V/C/14/01 Optional On Requet 01 02 03 04 05 06 07 Part No Decription 01 Rivet 02 Spring plate 03 Armature plate 04 Friction plate

a his far WSW WaW Z-Nu 4 sizet/ Patented Apr. 11, I APPLICATION FILED JULY 14, 1921, 22/ 33 G, J, BAUMSTARK, 0CK, Best SSSSSS47

1,412,600. G, J, BAUMSTARK, 0CK, APPLICATION FILED JULY 14, 1921, Patented Apr. 11, 1922. 2 SHEETS-S HEET, - I - - - a his far WSW WaW Z-Nu 4 Sira, Best SSSSSS47 2 22/ 33 sizet/ 4.42. 1,412,600. G, J,

1,412,600. G, J, BAUMSTARK, 0CK, APPLICATION FILED JULY 14, 1921, Patented Apr. 11, 1922. 2 SHEETS-S HEET, - I - - - a his far WSW WaW Z-Nu 4 Sira, Best SSSSSS47 2 22/ 33 sizet/ 4.42. 1,412,600. G, J,

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

United States Patent (19) Latta, Jr.

United States Patent (19) Latta, Jr. 54 SCHOOL BUS STOP SIGN AND CROSSING ARM APPARATUS 75) Inventor: Joseph E. Latta, Jr., Hillsborough, N.C. 73 Assignee: Specialty Manufacturing Co., Charlotte, N.C.

United States Patent (19) Latta, Jr. 54 SCHOOL BUS STOP SIGN AND CROSSING ARM APPARATUS 75) Inventor: Joseph E. Latta, Jr., Hillsborough, N.C. 73 Assignee: Specialty Manufacturing Co., Charlotte, N.C.

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989

![United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989](/thumbs/80/81257393.jpg) United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 54 MAGNETICFORCE GENERATING 56 References Cited METHOD AND APPARATUS U.S. PATENT DOCUMENTS 4,074,153 2/1978

United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 54 MAGNETICFORCE GENERATING 56 References Cited METHOD AND APPARATUS U.S. PATENT DOCUMENTS 4,074,153 2/1978

809,643. June 9, le A. E. SMALL RAILWAY CAR DROP DOOR

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

3,114,326 12/1963 Yaindi... 62/55 3,206,110 9/1965 Waibel /567 3,260,217 7/1966 Thresher /569

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 11 Patent Number: 45 Date of Patent: Nov. 25, 1986 (54) ELECTROMAGNETIC CLUTCH 75) Inventor: Takatoshi Koitabashi, Annaka, Japan 73 Assignee: Sanden Corporation, Gunma,

United States Patent (19) Koitabashi 11 Patent Number: 45 Date of Patent: Nov. 25, 1986 (54) ELECTROMAGNETIC CLUTCH 75) Inventor: Takatoshi Koitabashi, Annaka, Japan 73 Assignee: Sanden Corporation, Gunma,

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

Jan. 15, 1957 W. C. MESSICK 2,777,416 FIRE ALARM DEWECE AN35 QSS A. INVENTOR WARD C MESSECK. 6.1%a-4 2. sy/2c. a 77 o Aem at Ys

Jan. 1, 197 W. C. MESSICK FIRE ALARM DEWECE Filed Nov., 13, l93 2. Sheets-Sheet l 27 AN3 N QSS NS S. S A. INVENTOR WARD C MESSECK BY sy/2c 6.1%a-4 2 a 77 o Aem at Ys Jan. 1, 197 W. C. MESSECK FIRE ALARM

Jan. 1, 197 W. C. MESSICK FIRE ALARM DEWECE Filed Nov., 13, l93 2. Sheets-Sheet l 27 AN3 N QSS NS S. S A. INVENTOR WARD C MESSECK BY sy/2c 6.1%a-4 2 a 77 o Aem at Ys Jan. 1, 197 W. C. MESSECK FIRE ALARM

United States Patent (19) Tolleson et al.

United States Patent (19) Tolleson et al. 11 Patent Number: Date of Patent: Sep. 26, 1989 54 (75) 73 21 (22) (51) (52) 58) 56 FLEXBLE BACKREST ASSEMBLY FOR A CHAIR Inventors: Thomas H. Toleson, Morristown;

United States Patent (19) Tolleson et al. 11 Patent Number: Date of Patent: Sep. 26, 1989 54 (75) 73 21 (22) (51) (52) 58) 56 FLEXBLE BACKREST ASSEMBLY FOR A CHAIR Inventors: Thomas H. Toleson, Morristown;

43.4cule?o (26-12% Dec. 28, V. HAMMAR ET AL 2,103,670 WHEELED FIREARM. Z-1 ule 772 or /eta A?at 777-r. Filed Nov. 23,

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

PATENTED JULY 17, No , I. N. MOORE, DUPLEX STEAM ENGINE, A PLICATION FILED APR, 7, 1904, 3 SHEETS-SHEET 1. SY SY.

No. 825 924, I. N. MOORE, DUPLEX STEAM ENGINE, A PLICATION FILED APR, 7, 1904, PATENTED JULY 17, a 1906. 3 SHEETS-SHEET 1. 4 Witnesses: SY SY -? ZA No. 825,924, PATENTED JULY 17, 1906.? I, N, MOORE, DUPLEX