No. 523,790. Patented July 31, if f(i) is.

|

|

|

- Susanna Cole

- 5 years ago

- Views:

Transcription

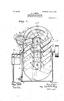

1 (No Model.) 4. Sheets-Sheet 1. ae J. B. HILL. TRACTION DITCHING MACHINE, No. 523,790. Patented July 31, if f(i) is. lifiesses 6y his Aftörpeys, piegför Jone? A. Hill. 101 sil 6%-ié. THE Norris PETERs co, PHOTo-LTHo, WASHINGTON, D. C.

2 (No Model.) 4. Sheets-Sheet 2. J. B., HILL. TRACTION DITCHING MACHINE, No. 523,790, Patented July 31, 1894, r N : s see t s Janues A. Hell.

3 (No Model.) 4. Sheets-Sheet 3. J. B. HILL. TRACTION DITCHING MACHINE, No. 523,790, Patented July 31, 1894, N -S y YS N N Ip?eplár Wiiposses & ---as-stré-i 3. s A. &zer A.A.(AZ. r ls Jöy Avis Afférpys, b the NORRIS PETERS co, PHOTO-LiTHo. washington, d. c.

4 (No Model.) 4. Sheets-Sheet 4. J. B. HILL, TRACTION DITCHING MACHINE, No. 523,790, Patented July 31, 1894, Switz III: See James A. Azzo. the NORRIS feters Co. Photo-it-yo. washington, D.c.

5 UNITED STATES PATENT OFFICE. JAMES B. HILL, OF BOWLING GREEN, OHIO. TRACTION DITCH IN G-MACHINE. SPECIFICATION forming part of Letters Patent No. 523,790, dated July 31, Application filed January 8, 1894, Serial No. 496,073, (No model.) To all, whom it may concern. Referring to the accompanying drawings, Beit known that I, JAMESB. HILL, a citizen of the United States, residing at Bowling the numerall designates the engine frame of Green, in the county of Wood and State of the herein described traction ditcher, and the 55 Ohio, have invented a new and useful Traction engine frame1 is supported for transportation Ditching-Machine, of which the following is on the front and rear axles 2 and 3 respect a specification. ively, the front axle 2, being preferably piv This invention relates to traction ditching otally connected to the front end of the frame, machines; and it has for its object to con whereby the direction of travel may be prop O struct a steam propelled ditching machine erly regulated, and said front axle carries the which shall provide efficient means for com advance wheels 4, while loosely mounted on pleting a continuous ditch with a perfect grade the opposite ends of the rear axle 3 are the line at the bottom adapted for the reception wide traction wheels 5, provided upon their of the ordinary drain tiles. peripheries with the calks 6, which secure a To this end the main and primary object o firm purchase or tread on the ground, whereby 65 the present invention is to provide a traction the entire machine may be moved forward in tile ditcher which may be conveniently pro response to the propelling engine thereof, and pelled from place to place, while at the same to provide for properly guiding the machine, time providing means for properly digging a the turning chains 7, are connected to the trench of any length or width desired, at the front axle 2, near the opposite ends thereof, and wind and unwind on the transverse ad same time the machine is being propelled for ward. justing shaft 8, journaled transversely on the With these and other objects in view which frame, and carrying at one end the worm gear will readily appear as the nature of the in wheel 9, with which meshes the worm 10 at vention is better understood, the same con the inner end of the guiding shaft 11 jour 75 sists in the novel combination, construction, maled at one side of the frame and carrying and arrangement of parts hereinafter more at its upper rear end the hand wheel 12, dis posed conveniently near to the operator's fully described, illustrated and claimed. In the drawings:-figure 1 is a perspective platform 13, which is attached to one side of the rear frame extension 14. view of a traction ditcher constructed in ac cordance with this invention. Fig.2 is a top The frame extension 14, is a continuation plan view thereof. Fig. 3 is a central vertical of the engine frame 1 directly in rear of the longitudinal sectional view. Fig. 4 is a detail rear axle 3, to provide a frame for supporting plan view of the vertically adjustable wheel the excavating devices of the machine, and frame and the laterally extended dirt carrier to also provide means whereby these exca mounted thereon. Fig. 5 is a detail elevation vating devices may start a ditch from its very of a section of the ditching or excavating beginning, which is not possible in machines wheel. Fig. 6 is a detail view showing the pawl of that character in which the excavating de vices are located intermediate of the front and ratchet device of one of the traction wheels. Fig. 7 is a detail view of the rear supporting and rear ends of the frame, and this frame wheel or runner and the manner of mounting portion or extension 4 will be more particu the same in rear of the ditching or excavating larly referred to in connection with the exca wheel. Fig. 8 is a detail sectional view on the vating devices, to be hereinafter more par ticularly described. - line c-ac of Fig. 5. Fig. 9 is a detail eleva 95 tion of the clutch mechanism for throwing the The main part of the engine frame 1, sup excavating devices in gear with the traction ported on the wheel axles 2, 3, is designed to gearing. - Fig. 10 is a detail view of the level carry the propelling devices which move the ing or grading rod used in connection with machine forward, and also to operate the ex the sighting attachment on the ditching ma cavating. devices at the same time, and at a O chine. Fig. 11 is a detail view showing the convenient point intermediate of the front adjustable connection between the wheel and rear axles of the engine frame, a suitable frame and the dirt carrier frame. intermediate bed frame 15, is built, on which is mounted an ordinary cylinder engine 16,

6 528,790 supplied with the requisite steam from the boiler 17 mounted on the front end of the frame 1, and the engine 16, is provided with a reversing lever 17, extended also conven iently rear to the platform 13, whereby the direction of travel may be conveniently con trolled by the operator, who also has control of the engine itself by means of the valve lever, connected with the throttle valve in the O steam pipe leading from the boiler. It will thus be seen that the entire movement of the machine is conveniently under control of the operator on the platform13. The engine 16 is connected with the trans verse drive shaft 19, which is mounted in suit able bearings on the frame 1, and the inter mediate bed frame 15, and the engine drive shaft 19, has attached thereto for a sliding movement thereon, at one side of the inter mediate frame 15, an adjustable pinion. 20. The adjustable pinion 20 is provided at one side with a clutch hub 21, held in any ad justed position on the shaft 19, by the set screw 22, and the clutch hub 21 of the pinion 25 20, is adapted to be adjusted into engage ment with a corresponding clutch hub 23, pro jected from one side of a small sprocket wheel 24, mounted loosely on the shaft 19, and adapted to provide a connection for commu 30 nicating motion to the ditching or excavat ing devices when the machine is ditching, but when the machine is being propelled from point to point, the pinion 20 gears with a large gear wheel 25, mounted on a short coun 35 ter-drive-shaft 26. The short counter drive shaft 26, is journaled in suitable bearings at one side of the bed frame 15, and carries upon its other end outside of the frame 1, a small chain or sprocket wheel 27, over which passes 40 one end of the drive chain 28, the other end of which passes over and gives motion to the sprocket wheel 29, mounted on one end of the axle 3. The sprocket wheel29, carries at one side the ratchet hub 30, working at one 45 side of the traction wheel 5, and adapted to be engaged by the double U-shaped ratchet dog 31. The ratchet dog 31, is pivotally at tached to the said traction wheel and is pro vided with a short arm extension 32, to which is connected one end of a coiled spring 33, the other end of which is adapted to detach ably engage either of the spring eyes 34, on adjacent spokes of the traction wheel. By connecting the spring 33 with either of said 55 spring-eyes one end or the other of the double dog 31, engages the ratchet hub 30, according as it is desired to propel the machine forward or backward, it being seen that the double dog connects the sprocket wheel 29 with the adjacent traction wheel. The devices just described, form the trac tion part of the machine and provide means for propelling it forward and backward, and also for operating the ditching or excavating 65 devices supported by the rear frame exten sion14, which Ishall now proceed to describe. Arising from the rear frame extension 14, and at one side of the same are the front and rear pairs of guide uprights 35, which ac commodate there - between for vertical ad justment the front and rear ends of the hori Zontal vertically adjustable wheel-frame 36, and the front pair of said guide uprights 35, are provided with vertical grooves or ways 37, in which slide the front guide tongues 38, projected laterally from the front end of the 75 horizontal frame 36, in any suitable manner. so as to form a strong guide for that end of said frame, while the opposite side bars of the frame 36, are extended beyond the rear cross bar of the frame to form short guide arms 39, which slide against the inner faces of the guide uprights 35, at the extreme rear end of the frame extension 14, and thereby serve to hold the rear ends of the vertically adjustable wheel frame steady in its vertical adjustment. The vertical adjustment of this horizontal wheel frame is preferably accom plished by means of the adjusting chains 40, attached at their lower ends to the front and 90 rear ends of the frame 36, and winding and unwinding at their upper ends on the ad justing shafts 41. The adjusting shafts 41, are journaled at the top of each pair of the guide uprights 35, in the bearing boxes 42, se cured to the tops of said uprights, and at one end, the adjusting shafts 41, carry the sprocket wheels 43, over which pass the operating chains 44 leading from smaller sprocket wheels 45, mounted on short operating shafts 46. The short operating shafts 46, are jour. naled in suitable bearings 47, at one side of the frame extension 14, and carry upon their outer ends the operating hand wheels 48, which are disposed conveniently near the platform 13, whereby the operator can easily raise and lower the wheel frame 36, by sim ply manipulating the said wheels 48, as will be readily understood without further de scription. The horizontal vertically adjustable wheel frame 36, is an open rectangular frame con sisting preferably of connected side and end bars, and suitably bolted to the rear end of said frame is an upright standard frame 49, consisting of the parallel spaced bars 50, which extend above the top of the frame 36 to form an attachment for the lower end of the rear adjusting chain 40, and also the braces 51, attached thereto and to the said wheel frame 36. The parallel spaced bars 50, comprising the upright standard frame 49, carried by the wheel frame, are adapted to accommodate therebetween the upper end of the detachable wheel standard 52. The detachable wheel standard 52, is pro vided at a point intermediate of its ends with the stop cleat 53, which limits its upward in Sertion in the standard frame 49, and at its lower end, the said standard is bifurcated as at 54, to accommodate the rear supporting wheel 55. This rear supporting wheel 55 is intended to be placed in position after a ditch or trench has been started, and is intended 95 IOO O II5 I 25

7 3o O to travelin the bottom of such ditch or trench and form a support for the rear end of the ditching or excavating apparatus, and this wheel attachment also carries a forwardly curved dirt shoe 56, the lower end of which travels in close proximity to the bottom of the ditch or trench. - The dirt shoe 56, is bolted at its upper end to the standard 52, and is braced in front of the wheel 56, by means of suitable braces 57, secured thereto and to the lower bifurcated end 54, of said wheel standard. The said for wardly curved rear dirt shoe 56, is substan tially semi-circular in cross section as well as being shaped in the arc of a circle, and is intended to form a dirt fender for the ditch ing or excavating wheel 58, which travels in close proximity to the rear dirt shoe, and would otherwise drop crumbs or small por tions of dirt back into the ditch or trench al ready excavated, if it were not for such shoe which directs all material, caught thereby, back again into that portion of the ditch through which the buckets of the wheel 58, pass. The ditching or excavating wheel 58, is cir cular in shape and works inside of the hori Zontal vertically adjustable wheel frame 36, between the opposite side bars thereof, and this ditching or excavating wheel principally comprises the parallel spaced wheel rims 59, which are made of a suitable thickness and width of steel to withstand the work required of the wheel. The said spaced wheel rims are separated to leave a space there-between for the proper operation of the wheel when discharging the material collected thereby, and said wheel rims are held spaced apart and are firmly connected by the intermedi ate transverse back plates 60. The trans verse back plates 60, are arranged at regul larly spaced intervals between the parallel wheel rims 59, and not only serve to space and connect the same, but also form the back walls of the U-shaped dirt buckets 61. The U-shaped dirt-buckets 61, are formed of suitable strength steel, and are fitted close at their rear edges against the upper project ing portions of the back plates 60, which pro ject beyond the outer edges of the wheel rims to complete the back of the said buckets, and the opposite edges of the buckets 61, are se cured by means of bolts, or other suitable de tachable fastening means, to the outside of the wheel rim 59. This construction provides a complete dirt bucket which spans the space between the wheel rims, and is designed to carry the dirt excavated from a ditch or trench up to the point of discharge, and directly in front of the open end of the dirt buckets 61 are arranged the U-shaped ditch cutters 62. The ditch cutters 62, are of substantially the same shape as the body of the bucket 6), but are detachably bolted at their opposite edges to the opposite wheel rims, at a point slightly in advance of the dirt buckets, whereby the entire strain of cutting the ditch is placed 528,790 3 upon the said ditch cutters, which are pro vided with outer beveled cutting portions 63, projecting beyond the top of the buckets 61 to provide means for properly digging the trench. - At a point intermediate of the advance ditch cutters 62, and the back plate of the next suc ceeding bucket are arranged opposite pairs of side cutters 64. The side cutters 64, are pro vided with angled lower ends 65, bolted to the outside of each of the wheel rims, and these angled ends 65 dispose the body or blade por tions of the cutters 64, out from the circle of movement of the wheel rims, and the buckets and advance cutters thereon, to provide means for lining up the sides of the ditch or itrench, being excavated, and thereby cutting a path sufficiently wide to permit of the body portion of the wheel passing clear through the ditchor trench without having any of its gear ing clogged with earth, and thereby interfer ing with the free operation of the wheel. By the adjusting devices described, the ditching or excavating wheel may be lowered to any depth desired to cut a ditch or trench of any depth to about four and one half feet, and by reason of the shape of the buckets and the ditch cutters, a ditch will be exca vated having a rounded bottom conveniently shaped for any of the ordinary sizes of tile, and as the said ditching or excavating wheel is put in motion, the buckets and cutters thereof will pick up the earth directly in ad Vance of the rear dirt shoe 56, and will then elevate it up to a point directly above the ver tical center or slightly at one side of the cen ter of the wheel, and while the earth is being elevated by the buckets the same is held in the buckets, and prevented from falling out, by plates means 66. of the short segmental bottom The short segmental bottom plate 66, is Supported in a stationary position between the lower edges of the wheel rims 59, at the front side of the center of the wheel, and in sufficiently close proximity to the inner edges of the back-plates 60, to form a substantial bottom for each bucket as it is carried over said bottom plate, and the latter has its up per end extend to a point substantially in a line above the center of the wheel, so that as each bucket passes beyond this upper end of the bottom plate, the contents thereof will. naturally be discharged from the space be tween the Wheel rims into the space formed inside of the upper portion of the ditching or excavating wheel, and onto the discharging devices to be more particularly referred to. The ditching, or excavating wheel 58, is provided on each side thereof with a circular rack flange 67. The rack flanges 67, consist of a series of short sections 67, bolted to the outer faces of each wheel rim at a point slightly in from the inner edges thereof to form a tragk for the combined supporting and centering wheels or rollers 68 and 63. The rollers 68, are mounted on each end of a o go 95 Ido O II5 I 25 13o

8 IO ) ,790 short roller shaft 70, journaled in the upper the lower gear shaft 85, journaled in suitable ends of suitable bearing arms or brackets 71, bearings at one side of one of the front guide secured to the opposite side bars of the wheel uprights 35, and the short bearing upright 85, frame 36, and rising above the same, and arising from one side of the engine frame. these rollers 68, are adapted to bear under The lower gear shaft 85, also carries at a point the inner edges of the circular rack flanges intermediate of its ends the large sprocket 67, and thereby form a portion of the support wheel 86, which receives one end of the for the revolving ditching or excavating sprocket chain 87, driven from the clutch wheel, while the rollers 69, are mounted on sprocket wheel 24, which is mounted loosely opposite ends of the lower adjustable roller on the shaft 19, and is turned by such shaft shafts 72, journaled at their extremities in when the clutch hub 21, is adjusted into en the V-shaped brace frames 73. gagement there with. The V-shaped brace frames 73, comprise When the machine is ready to excavate the separate diverging brace rods having at their ditch, the sprocket wheel 24, is coupled fast lower meeting ends bearings for the shafts 72, to the shaft 19, in the manner just described, while the other separated ends thereof are So that through the medium of the connec adjustably bolted as at 74, to suitable trans tions 87, 86, 85, 84, and 83, motion will be com verse supporting bars 75, extending trans municated to the ditching or excavating versely of the horizontal wheel frame 36, and wheel and cause the same to dig out a ditch suitably bolted thereto. The lower rollers 69, or trench, the depth or grade of which is prop are also supported to bear against the inner erly regulated by adjusting the wheel frame edges of the circular rack flange. 67, and not through the medium of the hand wheels 48, only serve to hold the ditching or excavating and at this point it may be well to note that wheel steady in its revolutions, but also assist a pawl and ratchet check 89, is connected in supporting the same, and by adjusting the with the shafts 46, to hold the excavating bolt ends 74, of the brace rods carrying the wheel properly in its adjusted position. lower rollers, the centering support for the The gearing just described provides means wheel may be properly adjusted to take u for turning or revolving the ditching or exca any wear of the operating parts, and thereby vating wheel when the machine is station hold the same steady in its movement. alry, but to advance a line of ditch it is nec A short attaching arm 76, is connected to the essary to propel the entire machine forward stationary bottom plate 66, and to one of the at the same time the ditching progresses, and frames 73, whereby the said bottom plate will to secure this result I employ a second upper be susceptible to a simultaneous adjustment gear shaft 90, journaled in suitable bearings with the said frames, thereby being properly directly above the lower gear shaft 85, and positioned at all times, and this stationary carrying at one end a large spur wheel 91, bottom plate is additionally braced in posi which is driven by the cog pinion 92, mounted tion at its upper end by an upper brace frame on the shaft 85, directly under the spur wheel. 77, attached thereto and to opposite sides Motion is thus communicated to the upper gear of the wheel frame 36, and said upper brace shaft 90, which further carries aloose sprocket frame 77, may support in position an upper wheel 93, provided at one side with a clutch horizoutal fender plate 78, to protect the gear hub 94, and accommodating thereon one end ing at this part of the machine from the dirt of a sprocket chain 95, the other end of which or earth which is discharged beyond the up passes over the sprocket wheel 96, made fast er terminal of the said bottom plate 66. on the short counter drive shaft 26, at one The opposite rack flanges 67, of the ditch side of the large gear wheel 25. ing or excavating wheel are engaged by the A sliding clutch sleeve 97, is feathered or opposite turning cogs 79, which are intended splined on the upper gear shaft. 90, at one to turn or revolve the ditching or excavating side of the clutch hub 94, and has connected wheel, and these turning cogs or cogwheels 79, there with an operating lever 98, mounted in are mounted inside of the frame 36, on the suitable guides on the front pair of guide up turning shaft 80, which carries on one end out rights 35, and disposed conveniently near to side of the wheel frame 36, a large sprocket the operator on the platform 13. wheel 81. The turning cogwheels 79, not only The adjustment which gears the ditching or mesh with the teeth of the rack flanges 67, to excavating wheel with the propelling engine communicate motion to the ditching or exca 16, has already been described, and to advance vating wheel, but are provided at their inner the ditching it is simply necessary to manipu sides with roller off-sets 82, which engage un late the operating lever 98 to throw the clutch der the inner edges of the rack flanges 67, so levers 97, into engagement with the hub or as to act in the capacity of supporting rollers clutch face of the sprocket wheel 93, and for the wheel in a correspondingly opposite thereby connect the upper gear shaft 90, with position to the upper supporting rollers 68. the short drive shaft 26, and thereby provide Motion is communicated to the turning means for simultaneously propelling the ma shaft 80, by means of the sprocket chain 83, chine forward and revolving the ditching or one end of which passes over the sprocket excavating wheel. This may be effected in wheel 81, while the other lower end thereof, a very short time as will be easily understood, engages the sprocket wheel 84, mounted on and by changing the size of the wheel 27, on OO Io5 II5 I 25

9 523,790 the changed shaft as 19, desired. the traction speed may be properly placed in position, and in order to The general operation of digging a ditch or accommodate the lowest possible adjustment trench and propelling the machine will now. of the carrier, as it may be lowered by the ad be apparent, and at this point it is to be noted justment of the wheel frame 36, the frame ex that after the buckets of the ditching or ex tension 14, is provided at one side with a drop cavating wheels carry the material beyond 116, of a width sufficient to accommodate the outer end of the said dirt carrier. The earth the upper end of the bottom plate 66, the same is discharged onto the inner end of the end which is discharged or delivered at one side O less dirt carrier 99. The endless dirt carrier of the machine by the laterally extending dirt 75 99, consists of an endless belt traveling around carrier is discharged against the dirt apron or the opposite end carrier rollers 100, the inner plate 117. The dirt apron 117, is swung on end of which carrier is journaled in suitable pivots 118, at its upper end, mounted in the bearing brackets or chairs 101, arising from off-standing bracket arms 119, projected from one side of the horizontal wheel frame 36, and one side of the frame extension 14, while to these opposite end carrier rollers 100, are also the lower end of the pivotally hung dirt apron held in position at the opposite ends of the is connected one end of the adjusting chains carrier frame , the other ends of which are attached to The carrier frame 102, consists of the oppo one side of the frame of the machine, to hold site frame sides 103, the inner ends of which the dirt apron at the properangle according to are provided with the off-sets 104, pivotally the position in which it is desired to line up the excavating dirt. mounted at the connection of the inner end of the carrier rollers with the brackets or The free discharge of the elevated earth, chairs 101, SO that the outer end of the car carried by the buckets up to the upper end 9o rier will be left free for adjustment, whereby of the bottom plate 66 is assisted by an auto the same may be disposed at the proper an matically operated bucket-cleaner 121. The gle, and this adjustment of the carrier frame bucket cleaner 121 is pivotally supported at may be secured by means of the short adjust 122, at the extreme upper edge of the bottom ing arms105, attached to one side of the wheel plate 66 and is provided with a cleaning arm. frame 36, and adjustably connected to the op 123, adapted to work inside of the buckets as 95 posite sides of thie carrier frame as at 106, they pass beyond the bottom plate, and at its whereby the same may be raised and lowered opposite ends is provided with a bell crank when desired. portion 124, to which is connected one end of The dirt carrier 99, is disposed at right an a spring 125, the other end of which is con OO gles to the horizontal wheel frame 36, and the nected with a suitable point of attachment to ditching or excavating wheel travels over the provide means for normally and sharply inner portion of this carrier, so as to de throwing the cleaning arm of the cleaner into posit the elevated earth onto the same, and the bucket to loosen up any dirt which might at the Outer end of the frame sides 103, of the cling therein. A series of pivotally connect fo5 carrier frame, are adjustably arranged the ing operating levers 126, are also connected bearing arms 107, which have a longitudinal to the bell crank end of the cleaner, and the adjustment on the frame sides as at 108, and outermost end of such levers is adapted to be form bearings for the outer one of the rollers struck by the back plate 60, of each bucket 100, and provide means for keeping the car as the wheel continues to revolve, so that the IO rier stretched at a proper tension. The inner cleaner will be rapidly vibrated in each one of the carrier rollers 100, has mounted on bucket as it passes to its discharging point one of the journal ends thereof the beveled directly above the discharge apron or car rier 99. gear wheel 109, meshing with a similar gear wheel110, mounted on the short motion shaft In most ditching machines no means are I I5 111, journaled in suitable bearing arms or provided for positively grading the bottom brackets 112, arising from opposite sides of line of a ditch so as to give the proper fall the wheel frame 36. A sprocket wheel 113, thereto, but in the present invention a verti is mounted on the motion shaft 111, interme cally adjustable sight rod 127, is mounted for diate of its ends, and receives one end of the vertical adjustment in the bracket 128, at tached to one side of the horizontal wheel sprocket chain. 114, the other end of which is driven from the sprocket wheel 115, mounted frame 36. This sight rod 127, is disposed in on the turning shaft 80, of the ditching or ex a line at one side of the platform 13, and is cavating wheel. This completes the gearing provided with an upper horizontal sight end whereby motion is communicated to the end 129, over which the operator takes a sight so I 25 less dirt carrier simultaneously with the move as to keep this end of the sight rod in a line ment of the ditching or excavating wheel and with a suitale leveling stake or target 130, the forward movement of the entire mauhine. such as shown in Fig. 10, of the drawings. The endless dirt carrier 99, is intended to The leveling stake or target 130, may be of deliver the dirt at one side of the ditch or any approved construction convenient for the trench being excavated, so as to line up the work, and is intended to be set up in a line excavated earthin a position convenient for with the ditch or trench to be excavated, and refilling the ditch after the tiling has been the moving part of the stake or target is ad justed at a proper height from the ground, so 3O

10 O ,790 that by adjusting the ditching or excavating ries of combined supporting and centering wheel to keep the upper sight end 129, al rollers supported in position above and be Ways in line with the adjusted part of the low the wheel frame, the lower set of rollers stake or target, a perfect grade of any desired being adjustably supported, an axleless ditch fall will be insured, and this grade will not ing or excavating wheel, mounted to turn on be affected by rocks or other obstructions in said rollers, and having an open center and a the path of the wheel owing to the fact that side delivering apron adjustably mounted on the ditching wheel is free to ride over such the wheel frame and having its fixed ends 75 obstructions and again fall back to cut or ex disposed under the discharging point of the cavate at the proper depth. ditching or excavating wheel, within the open The many advantages of the herein de center thereof substantially as set forth. Scribed traction ditcher will readily suggest 4. In a ditching machine, the combination themselves to those skilled in the art, and at with the wheeled frame; of the upright guide this point it may be well to again call atten frame, the horizontal vertically adjustable tion to the fact that by reason of mounting wheel frame mounted for vertical adjustment the ditching or excavating apparatus at the in said guide frame and carrying at one end extreme rear end of a traction engine, a ditch an upright standard frame, a bucket ditching may be started or taken up by the ditching or excavating wheel supported in the wheel 85 or excavating wheel at the very beginning, frame, a wheel standard adapted to be de thereby adapting the machine for use under tachably mounted in the lower end of said all conditions, besides many other important standard frame and carrying a rear support advantages belonging thereto, and I will have ing wheel, and a forwardly curved rear dirt it understood that changes in the form, pro shoe attached to said wheel standard and dis portion and the minor details of construc posed around the rear lower portion of the tion, may be resorted to without departing ditching or excavating wheel, substantially from the principle or sacrificing any of the as set forth. advantages of this invention. 5. In a traction ditcher, the combination of Having thus described the invention, what a traction engine having front and rear pairs 95 is claimed, and desired to be secured by Let of guide uprights extended above its frame, ters Patent, is a vertically adjustable wheel frame mounted 1. In a traction ditcher, the combination of for vertical adjustment between said guide the traction engine having a rearwardly ex uprights and carrying a series of rollers, a tended frame and guide uprights extended bucket ditching or excavating wheel mounted above said frame, an open center revolving to revolve on the rollers of the wheel frame, ditching or excavating wheel mounted for ver adjusting shafts journaled on top of said tical-adjustment between the guide uprights guide uprights and carrying at one end and geared with the engine, said wheel dis sprocket wheels, adjusting chains winding charging into its open center, a side deliv and unwinding on said shafts and attached to ering apron or carrier having itsinner endar opposite ends of said wheel frame, short op ranged in the open center of the wheel under erating shafts conveniently journaled at one the discharging point thereof, an automati side of the engine frame and carrying small cally operating cleaning device for relieving sprocket wheels at their inner ends and op the wheel from its load at the point of dis erating hand wheels at their outer ends, oper. charge, and a dirt deflecting apron arranged ating chains passing over said small sprocket at One side of the engine frame beyond the wheels and those at one end of the adjusting E. end of the carrier, substantially as set shafts, and a pawl and ratchet check device Ot. for each of said short operating shafts, sub 2. In a traction ditcher, the combination stantially as set forth. - With the traction engine, and the engine frame 6. In a ditching machine, a horizontal ver having a rear extension; of separate pairs of tically adjustable wheel frame, separate sets guide uprights extended above said frame ex of upper and lower combined supporting and tension, a wheel frame mounted for vertical centering rollers mounted above and below adjustment between said guide uprights, an the wheel frame, the lower set of rollers being axleless revolving ditching or excavating adjustable a revolving ditching or excavatirig wheel arranged to work within said wheel wheel having circular rack side flanges en frame, and a series of supporting wheels or gaged at their inner edges by said rollers, dirt rollers carried by the wheel frame and ar buckets, and cutters in advance of said buck ranged concentrically with the ditching or ex ets, and suitably operated cogwheels arranged cavating wheel to form a journal support to mesh with the teeth of said rack flanges, therefor, certain of said supporting wheels or and provided at one side with roller off-sets rollers being adjusted, substantially as set engaging under the inner edges of the rack forth. flanges to form a part of the wheel support, 3. In a traction ditcher, the combination substantially as set forth. - with the engine propelled frame; of the front 7. In a ditching machine, the combination and rear pairs of guide uprights, an open with the wheeled engine propelled frame hav horizontal wheel frame mounted for vertical ing a rear frame extension; of front and rear adjustment between said guide uprights, a se pairs of guide uprights extended from said Oo Io5 IO II5 I 25

11 O frame extension, and the front pair of which are provided with vertical guide grooves, a rectangular horizontally arranged wheel frame mounted for vertical adjustment be tween said guide uprights and provided at its front end with side guide tongues engag ing said vertical guide grooves and at its rear end with short guide arms sliding against the inner faces of the rear guide uprights, suit ably arranged supporting rollers mounted above and below the wheel frame, a bucket ditching or excavating wheel geared with the propelling engine and revolving on said sup porting rollers, and a detachable wheel at tachment connected with the rear end of the wheel frame and carrying a forwardly curved rear dirt shoe disposed around the rear lower portion of the ditching or excavating wheel, substantially as set forth. 8. In a ditching machine, the combination of the horizontal wheel frame carrying upper and lower sets of supporting rollers, a revolv ing ditching or excavating wheel having side flanges turning on said rollers and compris ing parallel spaced wheel rims, dirt buckets connecting the top edges of the rims and pro vided with back plates arranged in the space between the rims, and ditch cutters in ad vance of the buckets, and a suitably sup ported Stationary segmental bottom platear ranged in the space between the wheel rims and extending to a point above the center of the wheel, substantially as set forth. 9. In a ditching machine of the class de scribed, the combination with the partial sta tionary bottom plate; of the ditching wheel having parallel spaced wheel rims, U-shaped dirt buckets connecting the outer top edges of the rims and spanning the space between the same, said buckets having transverse back plates arranged between the rims, U shaped ditch cutters connecting the spaced rims in front of the buckets, and pairs of straight side cutters attached to the wheel rims between each ditch cutter and the next succeeding bucket, substantially as set forth. 10. In a ditching machine of the class de scribed, the combination of the vertically ad justable wheel frame carrying separate upper and lower sets of combined supporting and centering rollers, a revolving ditching wheel turning on said rollers and having a circum ferential series of bottomless dirt buckets, a segmental bottom plate attached to said wheel frame at one side of its center and extending up to a point above the center of the wheel beyond which the buckets thereof are emp tied of their contents, and a side delivery apron or carrier adjustably mounted at its inner end on the wheel frame inside of the upperportion of the revolving ditching wheel, substantially as set forth In a ditching machine of the class de scribed, the horizontal vertically adjustable wheel frame, a revolving bucket ditching wheel turning within the frame and provided at its oppositesides with circular rack flanges, 528,790 suitably arranged cog wheels geared with driving devices and meshing with the teeth of said rack flanges, an upper set of support ing rollers mounted above the wheel frame and bearing under the inner edges of said rack flanges, and W-shaped brace frames ad justably attached at their upper ends to the horizontal wheel frame and carrying at their lower ends a lower set of rollers adapted to also be held against the inner edges of said rack flanges, substantially as set forth. 12. In a ditching machine of the class de scribed, the combination of the wheeled 0 gine frame having a rear frame extension, the propelling engine mounted on the engine frame and having a main drive shaft, a short counter drive shaft geared directly with one of the traction wheels of the engine frame and adapted to be geared with the engine drive shaft when the ditching devices are inactive, the revolving ditching wheel mounted for vertical adjustment and revolution on the rear frame extension, the turning shaft for said ditching wheel, suitably arranged upper and lower gear shafts, the lower of which is con stantly geared with the turning shaft of the ditching wheel and the upper gear shaft and normally out of gear with the engine drive shaft, and means for throwing the upper One of said gear shafts into gear with the counter drive shaft when the lower one of said gear shafts is in gear with the engine drive shaft, substantially as set forth. 13. In a traction ditcher, the combination with the engine-propelled frame; of the hori zontal wheel frame mounted for vertical ad justment above the engine frame, a revolving ditching or excavating wheel supported for rotation within the wheel frame and having circular rack flanges on its opposite sides, a turning shaft mounted on the wheel frame and geared with the engine propelling de vices, said shaft carrying cogwheels meshing O with the teeth of said rack flanges and pro vided at one side with roller off-sets engaging under the inner edges of the rack flanges to form a part of the support for the wheel, a laterally extended dirt carrier or apron mounted at its inner end on the wheel frame II5 under the discharge of the ditching wheel, and gearing connected with said carrier apron and the turning shaft for the ditching wheel, substantially as set forth. 14. In a machine of the class described, the combination of the revolving ditching or ex cavating wheel having bottomless dirt buck ets, a segmental bottom plate to inclose the bottom of the buckets when loaded, and an automatically operating bucket cleaner, adapted to work into each bucket as it passes beyond said bottom plate, substantially as set forth In a ditching machine of the class de scribed, the combination of a stationary seg mental bottom plate, a suitably supported ditching wheel turning over said bottomplate and having bottomless dirt buckets inclosed 75 Od I o5

12 O ,790 at the bottom, when loaded, by said bottom endless dirt carrier mounted on said rollers, plate, a spring-lifted bent cleaning arm sup substantially as set forth. ported in position at the upper terminal of 19. In a ditching machine, the combination the segmental bottom plate and adapted to of a bucket ditching wheel discharging at the Work into each bucket as it discharges be top, a laterally extended dirt carrier arranged yond said bottom plate, and a series of trip at its inner end under the top discharging levers suitably connected to one end of said point of said wheel, suitably arranged bracket cleaning arm, the outer of which levers is arms, a dirt apron or plate having pivots at engaged by the back plate of each bucket to its upper end mounted in said bracket arms, impart a vibrating motion to the cleaning said dirt apron or plate being disposed be arm, Substantially as set forth. yond the outer end of said dirt carrier, and 16. In a traction ditcher, the combination means for adjusting the lower swinging end with a traction engine having a guide frame of said apron or plate, substantially as set at the rear end thereof; of a horizontal wheel forth. frame vertically adjustable in said guide 20. In combination with suitable leveling frame and carrying separate sets of combined Stakes or targets, of a traction ditching ma supporting and centering rollers, a bucket chine having vertically adjustable ditching ditching wheel turning on said rollers within devices, a fixed bracket arm secured at one the wheel frame and discharging at the top, side of the machine frame, and a sight rod a laterally extended dirt carrier or apron ad adjustably mounted for vertical movement justably mounted at its inner end on the in said brackets and provided with an upper wheel frame directly beneath the discharging angled sight-end adapted to be kept in line point of the buckets thereof, and a dirt de with said leveling stakes or targets to insure flecting apron suitably arranged at one side a grading of the ditch, substantially as set of the engine frame beyond the outer end of forth.... said carrier, substantially as set forth. 21. The traction ditching machine, the 17. In a machine of the class described, the wheeled frame carrying the traction and ditch combination of the engine propelled frame ing devices and the rear axle of which carries having a drop at one side, a bucket ditching loose traction wheels on its ends, a sprocket wheel mounted for adjustment and revolu wheel mounted on one end of the rear axle...tion on the frame, a laterally extended dirt adjacent to one of the traction wheels and carrier mounted within the top discharge por geared with the propelling devices, said tion of the wheel and adapted to work into Sprocket wheel having a ratchet hub at one the side drop of the frame as said ditching side, a double U-shaped ratchet dog pivotally wheel is lowered, and a dirt deflecting apron mounted at the inner side of one of the trac adjustably suspended at one side of the frame tion wheels and provided with a short arm beyond the outer end of the dirt carrier, sub extension, a coiled spring attached at one end stantially as set forth. to the short arm extension of said dog and 18. In a ditching machine, the combination adapted to have its other end connected to a with the vertically adjustable wheel frame point of attachment at either side of the pivot and the top discharging bucket ditching wheel of said dog to shift the engagement thereof Supported for rotation within said wheel with the ratchet hub, substantially as set frame; of a carrier frame pivotally mounted forth. at its inner end on said wheel frame and hav In testimony that I claim the foregoing a ing adjustable bearing arms at its outer end, my own I have hereto affixed my signature in an adjustable connection between the carrier the presence of two witnesses. frame and said wheel frame to adjust the in JAMES B, HILL. clination of the carrier frame, carrier rollers mounted at each end of the carrier frame, Witnesses: and the outer of which is journaled in said JOHN H. SIGGERS, bearing arms to be adjusted thereby, and the GEO. C. SHOEMAKER o 95

F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, , SHEETS-SHEET 2. ssna

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 3-vi-ucvtot 21, 6)) 7/4-ee-d

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

UNITED STATES PATENT OFFICE

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

"(2.4% May 4, 1954 C. A. GUSTAFSON 2,677,202. Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet CAR. A.

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

Feb. 14, 1967 R. B. WENGER 3,304,094 CLIMBING WHEEL CHAIR A/C. Z. 5 is INVENTOR. a/caezo as a 7/gate, 57 d. 2. XO aoz. 1277aatavays.

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

& 9. Š. Aerary 4. Morazzzzzok. May 19, : 1,538,208. INVENTORS INTERNAL COMBUSTION MOTOR. atz Aazzzz c1. A1arclaezzf H. A. NORDWICK E. A.

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Az Z 1.357,665. Azzee/2Z27. Patented Nov. 2, y 24-cee?, A-6. vy

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

Jan. 14, ,421,236. Filed June 22, E, U, MOYER ATTORNEYS LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH. SAW MILL, No. 434,770, Patented Aug. 19, " -% -, -% (3-C 24-44/777-C- ATTORNEY.

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH No. 434,770, Patented Aug. 19, 1890. WITNESSES: INVENTOR 32" -% -, -% (3-C 24-44/777-C- ATTORNEY. (No Model.) 3. Sheets-Sheet 2. A, A, DE LOACH, No. 434,770.

(No Model.) 3 Sheets-Sheet 1. A. A. DE LOACH No. 434,770, Patented Aug. 19, 1890. WITNESSES: INVENTOR 32" -% -, -% (3-C 24-44/777-C- ATTORNEY. (No Model.) 3. Sheets-Sheet 2. A, A, DE LOACH, No. 434,770.

10-sea /2 72/7e/ * 22%,962a. PATENTED OCT, l0, l905, No. 801,754.

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

No. 858,740, :, PATENTED JULY 2, G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I.

No. 858,740, :, PATENTED JULY 2, 1907. G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I. No, 858,740, PATENTED JULY 2, 1907. G, J, MEYER, SOAK TANK APPARATUS,

No. 858,740, :, PATENTED JULY 2, 1907. G, J, MEYER, SOAKLANKAPPARATUS APPLICATION FILED DEO, 22, 1805, 8 SHEETS-SHEET 1. 69tseviyoo: I. No, 858,740, PATENTED JULY 2, 1907. G, J, MEYER, SOAK TANK APPARATUS,

?????????? 24,??: Aug. 12, ulazca S. CoMA/asa BY) J. S. CONNER 2,425,306. Filed April 26, 1945 INVENTOR. 2 Sheets-Sheet l

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

Aug. 12, 1947. J. S. CONNER RETRACTILE WING AND ANDING GEAR Filed April 26, 1945 2 Sheets-Sheet l INVENTOR. ulazca S. CoMA/asa BY)?????????? 24,??: Aug. 12, 1947, J. S. CONNER RETRACTILE WING AND LANDING

s l N 2. S Aoaaaz A. u?acasow M-74a/oway, Alaata(7 & March 30, 1965 R. E. JACKSON 3,175,811 INVENTOR. A/Oaavaaaata

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

1, Patented Sept. 5, J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, SHEETS-S HEET 1..

1,197.534. J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, 1915. Patented Sept. 5, 1916. 4. SHEETS-S HEET 1.. - if Amiris PETERs co., PHoro-it-yo. was ico. o. c. 1,197.534. J, A, NORTON. RRGANG

1,197.534. J, A, NORTON, RRIGAING APPARATUS, APPLICATION FILED DEC. 2, 1915. Patented Sept. 5, 1916. 4. SHEETS-S HEET 1.. - if Amiris PETERs co., PHoro-it-yo. was ico. o. c. 1,197.534. J, A, NORTON. RRGANG

43.4cule?o (26-12% Dec. 28, V. HAMMAR ET AL 2,103,670 WHEELED FIREARM. Z-1 ule 772 or /eta A?at 777-r. Filed Nov. 23,

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

Dec. 28, 1937. V. HAMMAR ET AL WHEELED FIREARM Filed Nov. 23, 19 4. Sheets-Sheet 1 n Z-1 ule 772 or /eta A?at 777-r t & 4' arran well. Werts 77 42tter Ala. e 77 43.4cule?o (26-12% Dec. 28, 1937. W. HAMMAR

United States Patent (19) Cronk et al.

United States Patent (19) Cronk et al. (S4) LANDING GEAR FOR ULTRALIGHT AIRCRAFT 76) Inventors: David Cronk, 1069 Eucalyptus Ave., Vista, Calif. 92025; Lyle M. Byrum, 1471 Calle Redonda, Escondido, Calif.

United States Patent (19) Cronk et al. (S4) LANDING GEAR FOR ULTRALIGHT AIRCRAFT 76) Inventors: David Cronk, 1069 Eucalyptus Ave., Vista, Calif. 92025; Lyle M. Byrum, 1471 Calle Redonda, Escondido, Calif.

628) it -cssos so D, B, EASTMAN, CABINET CLOSET, APPLICATION FILED JULY 7, 1911, 1,050,435. Patented Jan, 14, 1913, 2 SBEETS-SHEET, SaySSSSSSSSSS

D, B, EASTMAN, CABINET CLOSET, APPLICATION FILED JULY 7, 1911, 1,050,435. Patented Jan, 14, 1913, 2 SBEETS-SHEET, -- SaySSSSSSSSSS SSNSSay 628) it -cssos so D, B, EASTMAN, CABINET CLOSET, APPLICATION FILED

D, B, EASTMAN, CABINET CLOSET, APPLICATION FILED JULY 7, 1911, 1,050,435. Patented Jan, 14, 1913, 2 SBEETS-SHEET, -- SaySSSSSSSSSS SSNSSay 628) it -cssos so D, B, EASTMAN, CABINET CLOSET, APPLICATION FILED

HHRH. United States Patent (19) Lissaman et al. (11) Patent Number: 5,082,079 (45) Date of Patent: Jan. 21, 1992 (51) (54) (75) (73)

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

C. S. BRADLEY. ELECTRIC MOTOR. No. 439,102, Patented Oct. 28, n AA es'- Q wiza. -%%-4ge

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

United States Patent (19) Smith

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

Your interest is appreciated and hope the next 37 pages offers great profit potential for your new business. Copyright 2017 Frank Seghezzi

Description and comparison of the ultimate new power source, from small engines to power stations, which should be of interest to Governments the general public and private Investors Your interest is appreciated

Description and comparison of the ultimate new power source, from small engines to power stations, which should be of interest to Governments the general public and private Investors Your interest is appreciated

June 25, 1968 ROTH 3,389,738 WINDOW SHADE APPARATUS FG. 2ASE. 4b. NVENTOR LEO ROTH. was 11- a-40, 2.11u1 2y 7. A2-2.1a-42a (arte?. ATTORNEYS.

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

United States Patent (19) Woodburn

United States Patent (19) Woodburn 54 (76) 21) 22 (51) 52 58 56 MOTOR VEHICLE AND BOAT TRALER Inventor: Clarence A. Woodburn, 43884 Pioneer Ave., Hemet, Calif. 92344 Appl. No.: 329,163 Filed: Mar. 17,

United States Patent (19) Woodburn 54 (76) 21) 22 (51) 52 58 56 MOTOR VEHICLE AND BOAT TRALER Inventor: Clarence A. Woodburn, 43884 Pioneer Ave., Hemet, Calif. 92344 Appl. No.: 329,163 Filed: Mar. 17,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(11) 4,398,742. United States Patent (19) Sanders. (45) Aug. 16, Assistant Examiner-Mitchell J. Hill

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

3,136,172. June 9, Attorneys C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS. 2 Sheets-Sheet li

June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS 3,136,172 2 Sheets-Sheet li Attorneys June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTEOARD PROPULSION UNITS 3,136,172 Filed March

June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTBOARD PROPULSION UNITS 3,136,172 2 Sheets-Sheet li Attorneys June 9, 1964 C. D. STRANG SHIFT MECHANISM FOR OUTEOARD PROPULSION UNITS 3,136,172 Filed March

%24- # (64%ue A7 roaways. Aé26aer 7ay Aeawaz. Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

1,063,364 A. O. L0MBARD. TRACTION ENGINE, APPLICATI0N FILED JUNIE 25, 1910, Patented June 3, SHEETS-SHEET,

1,063,364 A. O. L0MBARD. TRACTION ENGINE, APPLICATI0N FILED JUNIE 25, 1910, Patented June 3, 1913. 3 SHEETS-SHEET, 1?063,364? A. O. LONIBARD. TRACTION ENGINE, APPLICATION FILED JUNIE 25, 1910. Patented

1,063,364 A. O. L0MBARD. TRACTION ENGINE, APPLICATI0N FILED JUNIE 25, 1910, Patented June 3, 1913. 3 SHEETS-SHEET, 1?063,364? A. O. LONIBARD. TRACTION ENGINE, APPLICATION FILED JUNIE 25, 1910. Patented

June 6, ,987,128 W. KREG SOIL, DAMMING IMPLEMENT. Filed June ll, Sheets-Sheet. Werner Arieg INVENTOR. &&. ~~~~

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

June 6, 1961 Filed June ll, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet ~~~~ Werner Arieg INVENTOR. &&. June 6, 1961 Filed June ill, 197 W. KREG SOIL, DAMMING IMPLEMENT 2 Sheets-Sheet 2 Werner Arieg

Sept. 17, ,104,112 J. W. CRAIL STAIR CLIMBING WHEEL CHAIR. Filed July 2, 1962

Sept. 17, 1963 J. W. CRAIL STAIR CLIMBING WHEEL CHAIR Filed July 2, 1962 3,104,112 United States Patent Office Patented Sept. 17, 1963 3,4,12 STAR CLMSNG WHEEL CHAR Jesse W. Crail, 3802 Edenhurst Ave.,

Sept. 17, 1963 J. W. CRAIL STAIR CLIMBING WHEEL CHAIR Filed July 2, 1962 3,104,112 United States Patent Office Patented Sept. 17, 1963 3,4,12 STAR CLMSNG WHEEL CHAR Jesse W. Crail, 3802 Edenhurst Ave.,

809,643. June 9, le A. E. SMALL RAILWAY CAR DROP DOOR

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

v13 % {Tl/65,365 77/zeop/lilu?g7'own. ' 39% I ' 1,215,614.v T. BROWN. MANURE SPREADER. - jnvenz or _

_ T. BROWN. MANURE SPREADER. 1,2,614.v APPLCATON FLED APR. o. 911. Patented Feb. 13, 1917. 2- SHEETS-SHEET l. fill/fill: A, H "// 1111111111111 v13 % {Tl/65,365 - jnvenz or _ 77/zeop/lilu?g7own. 39% 12527163

_ T. BROWN. MANURE SPREADER. 1,2,614.v APPLCATON FLED APR. o. 911. Patented Feb. 13, 1917. 2- SHEETS-SHEET l. fill/fill: A, H "// 1111111111111 v13 % {Tl/65,365 - jnvenz or _ 77/zeop/lilu?g7own. 39% 12527163

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

BY 4. earea Carence A. Aroppe/ INVENTOR. Afg. 5

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

1,702,475. Feb. 19, , F. FAHNG COIL WINDING MACHINE Filed June 27, sed. 3. Sheets-Sheet 1 INVENTOR WITNESSES: 6%s/fcA.

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0044499 A1 Dragan et al. US 20100.044499A1 (43) Pub. Date: Feb. 25, 2010 (54) (75) (73) (21) (22) SIX ROTOR HELICOPTER Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0044499 A1 Dragan et al. US 20100.044499A1 (43) Pub. Date: Feb. 25, 2010 (54) (75) (73) (21) (22) SIX ROTOR HELICOPTER Inventors:

April 22, 1969 R. R. MYERS 3,439,368 SWIMMING POOL CLEANER. Filled Jan. 3, //V/AA/7OA. aaaaya /7 a.a5. As / Al-Aza 47.4% r-77%---a A77 oawals

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

May 19, 1964 AT TORNEY 3,133,451. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT. Filed Dec. 28, 196l. 3. Sheets-Sheet 1 R CHARD J.

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

Aug. 11, Wa/ace M. Brown. W. M. BROWN 2,648,392 DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 INVENTOR: 2 Sheets-Sheet l

Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 2 Sheets-Sheet l BY INVENTOR: Wa/ace M. Brown Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS

Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS Filed July 5, 1950 2 Sheets-Sheet l BY INVENTOR: Wa/ace M. Brown Aug. 11, 1953 W. M. BROWN DRIVEN STEERABLE BOGEY FOR MULTIAXLE TRUCKS

Oct. 8, 1968 F. MELLON 3,404,927 BATTERY DISPENSER. Filed April 17, Sheets-Sheet. 2 CE. 2t c. el-n. e are. Iraverator, 7 e44 %-4-4, t/s.

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

No. 801,373. PATENTED 00T, 10, J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, HEETs-SHEET. Z2562/2ZZZ Aa27/2(272, inventor

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

2,407,010 ADAPTER HEAD FOR WELLS. Filed Aug. 8, Sheets-Sheet. Lester C. Hudson

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

April 5, G, E, SWANSON 2,113,007 CYLINDER LOCK. NS: S.S.S.S.S Né EEE SS W. a. <SNSSSSSSSS/fde. is E( 4 NN. p7 NSN NNNN N&zo 76 v7 /6 2/23 / NS

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

United States Patent (19) Miller, Sr.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

/z. 6. (No Model.) No. 628,161. INVENTOR. W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) AT TORNEY WNESSES:

No. 628,161. (No Model.) W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) /z. 6. WNESSES: INVENTOR BY AT TORNEY % ENORRS PETERs co, PHoro-Litho, washington, d. c. No. 628, 16. W. F. HOMMAN. SEAL

No. 628,161. (No Model.) W. F. HOMENAN. SEA, LOCK Application files Apr. 30, 1898.) /z. 6. WNESSES: INVENTOR BY AT TORNEY % ENORRS PETERs co, PHoro-Litho, washington, d. c. No. 628, 16. W. F. HOMMAN. SEAL

United States Patent (11) 3,552,663

United States Patent (11) 3,552,663 72 Inventor John Royals 21 E. Seminary Ave., Lutherville, Md. 21093 2 Appl. No. 781,550 (22 Filed Dec. 5, 1968 45) Patented Jan. 5, 1971 54 ICE SHAVING MACHINE 9 Claims,

United States Patent (11) 3,552,663 72 Inventor John Royals 21 E. Seminary Ave., Lutherville, Md. 21093 2 Appl. No. 781,550 (22 Filed Dec. 5, 1968 45) Patented Jan. 5, 1971 54 ICE SHAVING MACHINE 9 Claims,

United States Patent (19)

United States Patent (19) Hodgetts (54) (75) 73 (1) ) (51) (5) (58) (56) NTERNALLY MUNTED DRIVE MECHANISM FR A BELT-WINDING DRUM Inventor: Assignee: Appl. No.: Filed: Graham L. Hodgetts, Mars, Pa. Rolflor

United States Patent (19) Hodgetts (54) (75) 73 (1) ) (51) (5) (58) (56) NTERNALLY MUNTED DRIVE MECHANISM FR A BELT-WINDING DRUM Inventor: Assignee: Appl. No.: Filed: Graham L. Hodgetts, Mars, Pa. Rolflor

United States Patent (19) Muranishi

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

DAYMAN & FLORENCE W, PARPART, BY MARRIAGE Now For

No. 762,241. PATENTED JUNE 7, 1904. DAYMAN & FLORENCE W, PARPART, BY MARRIAGE Now For STREET SWEEPING MACHINE. APPLICATION FILED JULY 17, 1901, NO MODEL, 6 SHEETS-SHEET 1. y III s a IIIllinai : 28 by-losses:

No. 762,241. PATENTED JUNE 7, 1904. DAYMAN & FLORENCE W, PARPART, BY MARRIAGE Now For STREET SWEEPING MACHINE. APPLICATION FILED JULY 17, 1901, NO MODEL, 6 SHEETS-SHEET 1. y III s a IIIllinai : 28 by-losses:

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

USOOS239155A. United States Patent (19) 11 Patent Number: 5,239,155 Olsson (45) Date of Patent: Aug. 24, 1993

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

Nov. 19, 1963 W. J. LEE 3,111,246 SHIRT FOLDING MACHINE Filed May ll, Sheets-Sheet 1 INVENTOR. by A-4,5- anzawy &Arafat

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

"--/ July 14, ,140,708. Filed May 31, l962 J. J. PETAK ETA ROBERT RECHHELM SNOW AND ICE MELTER JOSEPH. J.

July 14, 1964 Filed May 31, l962 J. J. PETAK ETA 3. Sheets-Sheet INVENTORS JOSEPH. J. PETAK & ROBERT RECHHELM "--/.444.7 ATTORNEY July 14, 1964 J. J. PETLAK ETAL Filed May 31, 1962 5 Sheets-Sheet 2 INVENTORS

July 14, 1964 Filed May 31, l962 J. J. PETAK ETA 3. Sheets-Sheet INVENTORS JOSEPH. J. PETAK & ROBERT RECHHELM "--/.444.7 ATTORNEY July 14, 1964 J. J. PETLAK ETAL Filed May 31, 1962 5 Sheets-Sheet 2 INVENTORS

USOO582O2OOA United States Patent (19) 11 Patent Number: 5,820,200 Zubillaga et al. (45) Date of Patent: Oct. 13, 1998

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

US 20150292.498A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0292498A1 Williams (43) Pub. Date: Oct. 15, 2015 (54) OIL PUMPINGAPPARATUS INCLUDING A (52) U.S. Cl. CYCLOIDAL

US 20150292.498A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2015/0292498A1 Williams (43) Pub. Date: Oct. 15, 2015 (54) OIL PUMPINGAPPARATUS INCLUDING A (52) U.S. Cl. CYCLOIDAL

3 23S Sé. -Né 33% (12) United States Patent US 6,742,409 B2. Jun. 1, (45) Date of Patent: (10) Patent No.: 6B M 2 O. (51) Int. Cl...

(12) United States Patent Blanchard USOO6742409B2 (10) Patent No.: (45) Date of Patent: Jun. 1, 2004 (54) DEVICE FORTRANSMISSION BETWEEN A PRIMARY MOTOR SHAFT AND AN OUTPUT SHAFT AND LAWN MOWER PROVIDED