April 11, 1961 H. G. FACK 2,979,551 THERMOELECTRIC GENERATOR. C E 2 -IC D e ZX4%Z44444XZZZAAXX (C-44 ZZ (Z N + 2S3 - I NSN6E6 NN

|

|

|

- Tobias Ryan

- 5 years ago

- Views:

Transcription

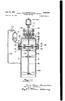

1 April 11, 1961 H. G. FACK THERMOELECTRIC GENERATOR Filed March 2, Sheets-Sheet C E 2 -IC D e ZX4%Z44444XZZZAAXX (C-44 ZZ (Z Nasir Yexas/SN N + 2S3 - I NSN6E6 NN &S II SNS SN. ". 2S y e al I (O BY In Ment dr H E R s C H E L G. Pa C / adat a T. To R n e Ys

2 April 11, 1961 Filed March 2, 1959 H. G. FACK THERMOELECTRIC GENERATOR 3. Sheets-Sheet 2 C E INVENTOR. HERs C - E L G. Pa C 3. BY a T to R n Ys

3 April 11, 1961 H. G. PACK THERMOELECTRIC GENERATOR Filed March 2, Sheets-Sheet 3 E. INVENTOR. -- H E R S C H E L G. Pack a T To R n EY s

4 United States Patent Office 1 THERMOELECTRIC GENERATOR Hersche G. Pack, 4308 Modoc Road, Santa Barbara, Calif. Filed Mar. 2, 1959, Ser. No. 796,403 8 Claims. (C ) My invention relates to improvements in thermoelec tric generators and it consists in the combinations, con structions and arrangements hereinafter described and claimed. An object of my invention is to provide a thermoelec tric generator in which the mechanical arrangement and construction is such as to provide a maximum of generat ing efficiency, while at the same time withstanding the damaging effects of heat. The device also makes any unused heat available for other use or for additional generation. The thermoelectric generator consists basi cally of a group of thermoelectric elements connected in electrical series. In certain cases the thermoelectric elements would be connected in electrical parallel for certain modes of operation. Other objects and advantages will appear as the speci fication continues and the novel features will be set forth in the appended claims. Drawings For a better understanding of my invention, reference should be had to the accompanying drawings, forming part of this specification, in which Figure 1 is a longitudinal section through one of the thermoelectric elements; Figure 2 is a transverse section taken along the line I-II of Figure 1; Figure 3 is an end view of Figure 4 and shows a num ber of the thermoelectric elements extending through openings provided in the end pieces; Figure 4 is a section taken along the line IV-V of Figure 3, and shows the thermoelectric elements sup ported by two end pieces. A heating chamber is formed between the two end pieces and a hot fluid is passed through the chamber for heating the central portions of the thermoelectric elements; Figure 5 is a top view of Figure 4 and illustrates a cooling tank connected to each end piece and enclosing the projecting ends of the thermoelectric elements; Figure 6 is an end view of Figure 5 when looking in the direction of the arrows V-VI of Figure 5; and Figures 7 to 10 inclusive are various wiring diagrams showing different uses of the thermoelectric generator. While I have shown only the preferred forms of my invention, it should be understood that various changes or modifications may be made within the scope of the annexed claims without departing from the spirit thereof. Detailed descriptions In Figure 1, I show a cross section of a unit thermo couple A, which is used in the thermoelectric gen erator Z, hereinafter described. The thermocuple com prises a thin-walled metal cylinder 1, which may be one and one half inches long and about one fourth inch in diameter. I do not wish to be confined to these meas urements, since they are merely given by way of exam ple. The thin metal cylinder is made of a heat resistant pmetal such as Inconel or better. Tungsten is preferable Patented Apr. 11, to use, but it is difficult to fabricate this metal. Between these two extremes of metal, there are numerous other metals or alloys which could be used as the material for the thin-walled cylinder. The mid portion of the cylinder, has an annular groove 2, so as to reduce the cross sectional area at this point. A thin coating. 3, of refractory ceramic material fills the groove 2, and the purpose of the coat ing is to protect the cylinder 1 from the deteriorating effects of heat. The inner surface of the metal cylinder 1 is lined with a thin layer 4, of ceramic material for the greater, part of the cylinder's length. This inner layer of ceramic affords an electrical insulation for the thre elements B, C and D, mounted within the cylinder. I mount the three rod-like elements B, C and D, within the ceramic insulating layer 4, so that they are free to slide within the cylinder. The center element B is only for electrically connecting the active or current produc ing elements C and D, and conveying heat thereto. The center heat-transferring element B may be a solid metal rod or of a special construction to attain certain effects such as a tube of quartz or ceramic with a bore 5, of small diameter in which is placed an electrically conduc tive material of a higher electrical resistance in reduced cross section than the active elements C and D. Tung sten or tungsten carbide 5a, could be placed in the bore 5. Thermoelectric element materials cover a very wide range from pure metals to semi-conductors and my inven tion seeks to provide optimum conditions for all types of metals used in forming the active elements C and D, and the center element B. Metallic elements tend to have low electrical resistance and change little with tem perature changes. Such metallic elements produce low voltage. An example would be a positive copper cur rent-producing element C and a nickel negative cur rent-producing element D, both being in contact with the center element B. Semi-conducting elements on the other hand, tend to be of a high resistance normally, and produce a rela tively high voltage. Their resistance, however, is much lower when hot and the resistance also decreases under mechanical pressure. Such semi-conducting elements do not follow Ohm's law, that is, their resistance drops with an increase in applied voltage. An example of a semi conductor thermocouple would be a positive element C of copper sulphide and a negative element D of lead sulphide. Alloy couples lie between good metal electrical con ductors and semi-conducting elements. An example of a negative alloy would be a Monel metal, of copper and nickel and a positive alloy of zinc and antimony. In addition, it is possible to have positive or negative ele ments C and D, made specifically to produce certain characteristics. This is accomplished by "doping' as in transistor materials and by various processes. "Dop ing' is a term much used in electronic literature and refers to the process of refining a material to a high purity and then adding minute amounts of a selected impurity to attain desired electrical properties. One group of thermocouple elements C and D is made of ceramic-like metallic oxides which become conductive at high temperatures. Elements of bismuth telluride are "doped' to produce couples for the "Peltier Effect which is a process of passing an electric current in the proper direction across a thermoelectric junction and thereby lower the temperature of the junction. The active elements C and D, are any two electrically conductive dissimilar materials. The elements C and D are held in electrical contact with the center element B, by adjustable screws 6 and 7, mounted in silicone rubber end plugs 8 and 9, respectively. The three elements B, C and D, are sealed in the cylinder 1, at all times to

5 3 prevent oxidation, and are under pressure to insure good electrical connection. If heat were applied to the ceramic layer 3, at the center of the cylinder, the resulting expansion would quickly loosen contact between the three elements B, C and D, creating high resistance and probably destroying contact altogether. The silicone rubber end plugs 8 and 9 could not stand the heat and would have to be cooled in some way. In all instances it is desirable to effect good electrical contacts and protect the elements B, C and O D, from the damaging effects of heat and air. I want to apply heat to the center of the cylinder 1, and I want to cool the ends of the cylinder to maintain a temperature differential between the center and the ends. In addition I want to apply pressure against the cylinder 5 ends and I want to use the screws 6 and 7, as electrical connections for wiring. I mount a plurality of the cylin ders 1, in a thermoelectric generator Z, of the type shown in Figures 3 to 6 inclusive. It is best to describe the construction of the generator Z, at the present time, 20 In the thermoelectric generator, I can have from one to an infinite number of unit thermocouples A. A gen erator would probably have one hundred such unit ther mocouples. For purpose of illustration, I have shown only nine unit thermocouples A, in the generator Z, of 25 Figures 3 to 6 inclusive. I use two stainless steel end pieces E and F and drill nine holes 10 in each. I place the nine cylinders, of the unit thermocouples A, in the nine aligned holes in the end pieces E, and F, and braze 30 or otherwise secure the cylinders in place so that their ends will project beyond the end pieces as clearly shown in Figure 4. This provides a rigid metal structure. I now place a layer of heat-resistant material on the inside wall of each end piece E and F. In Figure 4, these 35 two layers are shown at G and H. I then provide top and bottom ceramic pieces J and K, that extend between the two end pieces. E and F, and I also provide side ceramic pieces L. All of these pieces provide a heating chamber M, that lies between the end pieces E and F. 40 It is necessary to circulate hot fluid around the centers of the unit thermocouples A, so I provide the top piece with an outlet opening 11, and the bottom piece K with an inlet opening 2. Screws 13, or other suitable fas tening means may be used for securing the end pieces E and F, to the top and bottom ceramic pieces J and K. 45 The screws should not extend between the end pieces E and F. - It is further necessary to provide two cooling tanks to enclose the ends of the cylinders 11, projecting from the 50 end pieces E and F. In Figure 5, I show two cooling tanks N and P, one tank being placed at each end of the heating chamber M. The cooling tank N, consists of four walls forming a rectangle and the edges of the walls are attached to the end piece E, so as to make a liquid tight fit therewith. A cover plate 14, is secured to the other or exposed edges of the four walls by screws and a liquid-tight compartment is formed. The top wall 15, for the cooling tank N, has an electrode 6, extending there through and this electrode is insulated from the top wall. A wire 18, leads from the inner end of the electrode 16, to the screw 6, of one of the unit thermocouples A. The nine thermocouples A, are connected in series in Figure 3, and adjacent thermocouples are reversed in their positions so that only short wires 19, need be used to connect them in series with each other. The screw 7, of the last ther mocouple A, is then connected by a wire 20, to another electrode 17, which is mounted in and insulated from the top 21, for the cooling tank P. If the thermocouples A, are connected in parallel, instead of series, all of the screws 6, of the thermocouples would be arranged in one cooling tank N, and all of the screws 7, of the same thermocouples would be arranged in the other cooling tank P. All of the screws 6, would be connected to each other and to the terminal 16, while all of the screws 7, would be connected to each other and to the terminal 17. The metal end pieces E and F, are thicker than the walls of the metal cylinders 1. The tanks N and P, have pressure filler caps 22 and 23, in their tops and these caps are removed when the tanks are filled with fluid. The ends of the metal cylinders 1, project into the fluid. The openings 11 and 12, for the heating chamber M, are for the intake and exhaust of the heating fluid. The fluid would normally be combustion gases from burn ing fuel, but could be engine exhaust gases, heated air or a hot liquid. The heated fluid would enter the cham ber M, by the inlet 12, and would leave the chamber by the outlet 1. The cooling tank P, is closed by a cover plate 24, and Figure 6 shows the plate secured in place by Screws 25. The two cooling tanks N and P, have metal tubes Q and R, in them, respectively, through which water or other cooling fluid is circulated to remove heat from the cooling fluid in the tanks. The water flowing through the tubes Q and R, would be heated by the fluid in the tanks N and P, and this heated water could be used elsewhere. The fluid in the tanks N and P, would be a non-conductor of electricity such as silicone. The tanks N and P, are preferably made of stainless steel and may be heat insul lated in the same manner as boilers or hot water tanks are insulated. Gaskets may be placed-under the cover plates i4 and 24, to insure a fluid tight seal. The ends of the unit thermocouples A, that extend into the tanks N and P, are cooled by the fluid in these tanks and the ends will also be under hydrostatic pressure from the pressure of the silicone fluid in the tanks. Heat is transferred from the cylinders 1, to the active elements C and D, by the central heat transfer element B, and in addition, any electric current flowing through the active elements C and D, will generate heat in the heat transfer element B, where it will assist in thermoelectric genera tion of a current. The heat applied to the central area of the cylinders, by the hot fluid flowing through the heating chamber M, will be quickly conducted through the thin cylindrical wall to the center heat transfer ele ment B, which acts as a heat reservoir to accumulate heat and to heat the inner ends of the generating elements C and D. The elements C and D, in general, are relatively poor heat conductors. The thin cylinder walls of the unit thermocouples A, likewise offer a poor heat conductive path outward; hence the temperature tends to build up in the center section. The heat which does flow into the electrical generating elements C and D, in most cases, tends to lower their electrical resistance, a desirable fea ture as long as one end is at a much higher temperature than the other. How the special heat transfer element B, would likewise perform is evident and additional heat would be internally generated. This would, of course, be at the expense of adding some extra resistance to the generator. As already stated, the bore 5, of the center element B, is preferably filled with tungsten or tungsten carbide. Neither material has a higher specific resistance than the average thermoelectric element material, but due to the greatly reduced cross section of either of these two ele ments in the bore 5, of the quartz tube B, the resistance of this center element is greater than that of either the positive element C, or the negative thermoelectric element D. This is comparable to an ordinary electric lamp bulb where the small diameter tungsten filament heats to white heat while the supporting wires remain cool when current flows through the circuit. Therefore, the high resistance tungsten 5a will be heated. The silicon rubber end plugs 8 and 9, are fluid cooled by the fluid in the tanks N and P. The same fluid exerts an elastic pressure against the plugs to in turn cause the inner ends of the screws 6 and 7, to maintain good electrical contact between the elements C, D and

6 5 B, in the cylinders 1. The screws 6 and 7, are for at taining initial contact and for readjustment if required. The same hydraulic pressure on all of the cylinder ends by the silicon fluid in the cooling tanks, ensures uniform pressure and therefore good electrical contacts among the elements B, C and D, in each cylinder 1, at all times. The unit thermocouples A, are connected to each other in series to attain a higher voltage or they are con nected in parallel to attain a higher current. The use of a high resistant material. 5a of a reduced cross section because of the bore 5, provides a good heat transfer unit B. I have shown an arbitrary number of unit thermocouples A, and an arbitrary size of heating chamber M, in order to give one illustration of the thermo electric generator. An actual model would probably have one hundred unit thermocouples arranged in ten rows with ten units being in each row. It is desirable to have the heating chamber as narrow as practicable in order to limit the heating to the center portion of the unit thermocouple A. The metal tubes Q and R, for cooling the silicone fluid in the cooling tanks N and P, would be bent to expose more area of the tube walls to the fluid. The generator Z, will be surrounded by heat insulating material. Consideration is now given to the electric circuits shown in Figures 7 to 10, inclusive. In its simplest form, a group of thermocouples A, are connected in electrical series and when heat is applied to the heating chamber M, a voltage appears across the electrodes or terminals 16 and 17. If, instead of heating the chamber M, I connect a source of direct current to the output terminals 16 and 17, in opposite polarity to that for generating electricity, so that the negative wire would be connected to the positive terminal 16, and the positive wire would be connected to the negative terminal 17; cold will be produced in the heating chamber M, and heat will be produced in the cooling tanks N and P. My invention is particularly well adapted to operate either to generate current or to produce refrigeration. For the latter proc ess, special elements, for example doped bismuth telluride, are used. Referring to Figure 7, I have shown how my thermo electric generator can have its unit thermocouples A, heated by an alternating electric current instead of by a heated fluid flowing through the heating chamber M. A step down transformer S, has its primary coil 30, con nected to a source of alternating electric current and has its secondary coil 31, connected to the metal end pieces E and F, of the generator by wires 32 and 33. A switch 34 is placed in the secondary circuit for connect ing the metal end pieces to the alternating current. The unit thermocouples A, have their metal cylinders 1, brazed to the metal end pieces E and F, and therefore all of the metal cylinders will be connected in electrical parallel with the secondary circuit flowing through the wires 32 and 33. The unit thermocouples will have their cen tral portions heated by offering resistance to the alternat ing current and the thermocouples A, will deliver a direct current to the terminals 16 and 17, because the thermo couples are electrically connected to the terminals. The step down transformer S, is preferably of the type used in spot welding. The electrical heating of the centers of the unit thermocouples is enhanced because the metal cylinders 1, are reduced in cross sectional area by the annular grooves 2. The arrangement shown in Figure 7 can use a source of alternating current to produce heat in the unit thermocouples A, and these in turn will gen erate a direct current. Another method of using external voltage to heat th thermocouples A, and produce a direct current is shown 5 O element materials to the electric current are connected to the center terminals 34 and 35, of a double pole double throw switch T. Now, when the Switch T, is thrown to close the terminals 36 and 37, the terminals 16 and 17, are connected to the secondary 38, of a transformer U, and current flowing in the secondary cir cuit will generate heat, mostly in the heat transfer ele ments B, because they are of a higher resistance than the elements C and D. The terminals 16 and 17, could be connected to direct current if desired. The heat will be stored in the transfer elements B. Now when the switch T, is thrown to the other posi tion and connects with terminals 39 and 40, thermoelectric generation from the stored heat in the transfer elements B, will flow into the external circuit that leads to a storage battery V, or a work load W.. A switch 41, is used for connecting the work load to the storage battery. The work load W, can be connected directly to the terminals 39, aid 40, without the switch 41, if desired. It is thus seen that by alternately throwing the switch T, from one position to the other, a voltage is produced and an external current will flow. It will of course be obvious that electric heating of the unit thermocouples can be used in conjunction with other heating such as gases of combustion flowing through the heating cham ber M. - Consideration will now be given to means of feeding the output of the thermoelectric generator back through the generator to increase its efficiency. In Figure 9, when the double pole double throw switch X, connects with the terminals 42 and 43, the output of the generator Z, will flow into the storage units which may be the storage battery V, or a capacitor, not shown. When the switch X, is thrown to the other position and connects with terminals 44 and 45, the storage unit V, will be in series with the thermoelectric generator and will dis charge through the generator into the load W. In Figure 10, I show a multi-pole double throw switch Y, for connecting a plurality of storage units, such as the storage batteries V, with the thermoelectric generator Z, so that the batteries will be charged in parallel. A throwing of the switch Y, into its other position will connect the storage batteries in series with each other and in series with the work load W. The batteries V, will therefore be charged in parallel and discharged in series. I have shown how electric current fed back through the thermoelectric generator Z, can be used to produce heat to increase the output of the generator. Another advan tage of the feed back of electricity to the generator re Sults in the non-linear resistance of many thermoelectric This means that the resistance of the elements C and D, drops in proportion to the applied voltage. Therefore it is ob viously advantageous to discharge the storage devices V, in series through the generator Z. This is an advantage in addition to the general advantages of attaining as high an operating voltage as possible. It will be seen that the only moving mechanical part in the generator Z, and the associate electric circuit in Figure 10, is the multi-pole double throw switch Y. The switch Y, may be motor driven, which is preferable or be in the form of a relay. Little power is required to operate such a switch Y, and timing and cycling can be adjusted to conditions optimum for the particular opera 65 tion. in the structure of the thermoelectric generator Z, shown in Figure 5, the thermoelectric elements B, C and D, are connected in electrical series and are at all times 70 electrically insulated from the metal cylinders 1, by the insulating sleeves 4, and therefore are insulated from all in Figure 8. Assume that all of the unit thermocouples metal parts of the generator. The series circuit in each A, are loaded with generating elements C and D, sep unit thermocouple A, and the connecting of the thermo arated by the special heat conducting center element B, couples in series can be referred to as the thermoelectric and that the output terminals 16 and 17, of the generator 75 circuit. The silicone fluid in the cooling tanks N and

7 2,979,55. 7 P, is of course an electrical insulator and therefore the wires connecting the thermocouples will not be short circuited. The parallel circuits mentioned in Figures 7 and 8, is a heating circuit, and is a means of applying heat to the central portions of the metal cylinders. The principie ; cf: using electricity for heating the metal cylinders, makes use of the cylinders; themselves as resistance ele ments and therefore the cylinders will be heated. The re sistance of a group of metal cylinders, in parallel would be very low, but a heavy current at very, Iow voltage would heat them very well. Such electric heatr ing is obtainable from alternating current from a trans former. Since the centers of the metal cylinders. are thinner, the resistance will be greater and the heat will 15 tend to localize in these portions. By this ileans can use alternating current to produce heat in the generator : Z, and the generator in turn will produce direct current! electricity, by thermoelectric action. Both the input elec tric circuit into the generator Z, and the output direct; current circuit can and do function simultaneously. A short round, rod of copper or other: naeta can be used for the heat transfer element B. The special heat transfer element of quartz having the bore 5, filled with I tungsten 5a is for; the purpose of generating internal heat 25 when an electric current flows through the tungsten. There are thousands of materials; which will yield a thermoelectric voltage; when the materials are heated. Optimum operating conditions vary with the change of the elements B, C and D, and hence many variations of elements may be used in the generator Z. The wiring diagrams of Figures 9 and 1 C are more than a simple means of electrical storage; for the output of the generator. Z... These wiring diagrams might be thought of as analagous to a combustion engine where there is a compression stroke', and a "power stroke.' Here by means of the double throw cycling switches X and Y, the generator output is alternately stored; ten porarily in the storage batteries or capacitors, and then discharged through the generator Z, to produce a "power stroke' or pulse of power. I claim: 1. In a device of the type described: a unit thermo couple comprising a metal cylinder; a heat transfer ele ment at the center of the cylinder; a positive current producing element in the cylinder and contacting with the heat transfer element; a negative current-producing element in the cylinder and contacting with the heat transfer element; a current insulating sleeve separating the central heat transfer clement and the positive and negative current-producing elements from the metal cylinder; rubber plugs mounted in the ends of the cylin der and adjacent to the positive and negative current producing elements; and screws mounted in the plugs and being adjustable for contacting with the positive and negative current-producing elements for holding them in contact with the heat transfer element; said plugs sealing the cylinder ends to prevent the entrance of air into the cylinder and thereby prevent any damage to the contact ing surfaces among the elements due to oxidation caused by air. 2. The combination as in claim 1 : and in which the metal cylinder has an annular groove midway between its ends; and a layer of ceramic encircling the cylinder and being received in the groove. 3. The combination as set forth in claim 1 : and in which the heat transfer element is made of quartz and has a small bore therein extending from end to end of the element and filled with an electrical conductive ma terial of a higher resistance in reduced cross section than the resistances of the positive and negative current producing elements. 4. A thermoelectric generator comprising a heating chamber including two opposed end pieces with a plural 3 ity of openings in one end piece being aligned with a corresponding number of openings in the other end piece; a plurality of thermocouples disposed in the aligned openings and each including a metal cylinder; a central heat, transfer element mounted in each cylinder; a posi tive current-producing element housed within the cylin der, and placed at one end and a negative current-produc ing; element housed within the cylinder and placed at the other end of each central heat transfer element; said three elements constituting thermoelectric elements; the ends of the metal cylinders projecting beyond the two opposed end pieces of the heating chamber; an electrical insulat ing sleeve placed between the three thermoelectric ele ments and the metal sleeve; a cooling tank enclosing: the cylinder ends projecting from one end piece; a second Cooling tank enclosing the cylinder ends projecting from the other end piece; insulating plugs closing the ends of the metal-cylinders; screws carried by the plugs and con tacting with the adjacent ends of the current-producing elements for keeping thern in contact with the central heat-transfer elements; an electric non-conducting fluid under pressure filing the two cooling tanks and exerting a uniforin pressure against the Screws and plugs for inaintaining the three elements, in each cylinder in con tact with each other; wires connecting the screws in an electrical circuit; and means for heating the central por tions of the cylinders disposed in the heating chamber for 40. midportions of the cylinders, causing the central heat-transfer elements to be heated and in turn heat the two current-producing elements in each cylinder for; generating electricity that will flow through the wires forming the electric circuit. 5. The combination as set forth in claim 4: and in which the central portions of the cylinders have annular external grooves; and a layer of ceramic encircling the cylinders and being received in the grooves. 6. The combination as set forth in claim 4; and in which means is provided for cooling the liquid in the two tanks for maintaining the ends of the metal cylinders pro jecting into the tanks at a cooler temperature than the 7. A thermoelectric generator comprising a heating chamber including two opposed metal end pieces having openings and arranged parallel to each other so that the openings in one piece are aligned with the openings in the other; a plurality of thermocouples each including a metal cylinder that projects through aligned openings pro vided in the metal end pieces; the portions of the metal cylinders lying between the end pieces offering resistance to a current flowing from a current source through one end piece, then through the cylinder portions and then through the other end piece and back to the source; the cylinder portions through which the current flows being heated; a central heat transfer element disposed in each cylinder and being heated by the heated cylinder portion; a positive current-producing element and a negative cur. rent-producing element disposed in each cylinder, one being disposed at each end of the central element and contacting therewith; an electrical insulating sleeve for insulating the central element and the two current-pro ducing elements from the metal sleeve; said positive and negative current-producing elements when heated by contact with the central heat transfer unit, generating electricity; and wires electrically connected to the active elements for conveying the electricity generated by the active elements. 8. A thermoelectric generator comprising a pair of terminals; a plurality of unit thermocouples electrically connected to the terminals; each unit thermocouple in cluding a metal cylinder housing a central heat transfer element and a positive current-producing element and a negative current-producing element in contact with the central element; an electrical insulating sleeve for in sulating the central element and current-producing end elements from the metal sleeve; the central element being

8 heated due to resistance when electricity passes there through; and a switch and wiring for connecting the ter minals to a source of current for causing current to flow through the three elements in each thermocouple for heating the central elements; said switch being operable for disconnecting the current source from the terminals and for connecting the terminals to an external circuit for storing or using the current for work that is gener rated by the current-producing elements. 2,215,332 2,232,961 2,710,936 2,780,765 2,844,638. 2,844, References Cited in the file of this patent UNITED STATES PATENTS Milnes Sept. 17, 1940 Milnes Feb. 25, 1941 Lowry et al June 14, 1955 Chapin et al Feb. 5, 1957 Lindenblad July 22, 1958 Jordan July 22, 1958

United States Patent (19) 11) 4,324,219

United States Patent (19) 11) 4,324,219 Hayashi 45) Apr. 13, 1982 54). SPARK INTENSIFIER IN GASOLINE 56) References Cited ENGINE U.S. PATENT DOCUMENTS s 703,759 7/1902 Brown... 123/169 PH 75) Inventor:

United States Patent (19) 11) 4,324,219 Hayashi 45) Apr. 13, 1982 54). SPARK INTENSIFIER IN GASOLINE 56) References Cited ENGINE U.S. PATENT DOCUMENTS s 703,759 7/1902 Brown... 123/169 PH 75) Inventor:

(12) Patent Application Publication (10) Pub. No.: US 2015/ A1

(19) United States US 20150214458A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0214458 A1 Nandigama et al. (43) Pub. Date: Jul. 30, 2015 (54) THERMOELECTRIC GENERATORSYSTEM (52) U.S. Cl.

(19) United States US 20150214458A1 (12) Patent Application Publication (10) Pub. No.: US 2015/0214458 A1 Nandigama et al. (43) Pub. Date: Jul. 30, 2015 (54) THERMOELECTRIC GENERATORSYSTEM (52) U.S. Cl.

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

United States Patent 19

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010O231027A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0231027 A1 SU (43) Pub. Date: Sep. 16, 2010 (54) WHEEL WITH THERMOELECTRIC (30) Foreign Application Priority

(19) United States US 2010O231027A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0231027 A1 SU (43) Pub. Date: Sep. 16, 2010 (54) WHEEL WITH THERMOELECTRIC (30) Foreign Application Priority

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 01 17420A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0117420 A1 Kim et al. (43) Pub. Date: May 19, 2011 (54) BUS BAR AND BATTERY MODULE INCLUDING THE SAME (52)

US 2011 01 17420A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0117420 A1 Kim et al. (43) Pub. Date: May 19, 2011 (54) BUS BAR AND BATTERY MODULE INCLUDING THE SAME (52)

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

March 12, ,080,723. Award AAce ELECTRIC. HEATING AND/OR COOLING BLANKET. 4. Sheets-Sheet l E. FP, FPRICE INVENTOR.

March 12, 1963 E. FP, FPRICE ELECTRIC. HEATING AND/OR COOLING BLANKET 3,080,723 4. Sheets-Sheet l 3. 42 Award AAce INVENTOR. March 12, 1963 E, FP, PRICE 3,080,723 ELECTRIC HEATING AND/OR COOLING BLANKET

March 12, 1963 E. FP, FPRICE ELECTRIC. HEATING AND/OR COOLING BLANKET 3,080,723 4. Sheets-Sheet l 3. 42 Award AAce INVENTOR. March 12, 1963 E, FP, PRICE 3,080,723 ELECTRIC HEATING AND/OR COOLING BLANKET

2,376,968. May 29, F. M. JONES TWO-CYCLE GAS ENGINE. 2 Sheets-Sheet li. Filed Dec. 26, 1942 FIG, vucinto FREDERICK M. JONES.

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

March 27, 1956 T. A. DOURDEVILLE 2,739,366

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

ROLL-DRIVING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, 193 4. Sheets-Sheet l K i Fi 9. ée INVENTOR, THEODORE A DOURDEVILLE, 4-y ATTY. ROLL-DRIWING MECHANISM FOR A NAPPING MACHINE Filed Oct. 26, l93

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

& 9. Š. Aerary 4. Morazzzzzok. May 19, : 1,538,208. INVENTORS INTERNAL COMBUSTION MOTOR. atz Aazzzz c1. A1arclaezzf H. A. NORDWICK E. A.

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

(12) United States Patent

(12) United States Patent Nishiyama et al. USOO6174618B1 (10) Patent No.: (45) Date of Patent: Jan. 16, 2001 (54) BATTERY HOLDER (75) Inventors: Koichi Nishiyama; Yoshinori Tanaka; Takehito Matsubara,

(12) United States Patent Nishiyama et al. USOO6174618B1 (10) Patent No.: (45) Date of Patent: Jan. 16, 2001 (54) BATTERY HOLDER (75) Inventors: Koichi Nishiyama; Yoshinori Tanaka; Takehito Matsubara,

April 24, 1951 LE ROY S. schell, JR 2,550,500

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

US 20170 1261.50A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0126150 A1 Wang (43) Pub. Date: May 4, 2017 (54) COMBINED HYBRID THERMIONIC AND (52) U.S. Cl. THERMOELECTRIC

US 20170 1261.50A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0126150 A1 Wang (43) Pub. Date: May 4, 2017 (54) COMBINED HYBRID THERMIONIC AND (52) U.S. Cl. THERMOELECTRIC

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

I lllll llllllll

I lllll llllllll 111 1111111111111111111111111111111111111111111111111111111111 US005325666A United States Patent 1191 [ill Patent Number: 5,325,666 Rutschmann [MI Date of Patent: Jul. 5, 1994 [54] EXHAUST

I lllll llllllll 111 1111111111111111111111111111111111111111111111111111111111 US005325666A United States Patent 1191 [ill Patent Number: 5,325,666 Rutschmann [MI Date of Patent: Jul. 5, 1994 [54] EXHAUST

Az Z 1.357,665. Azzee/2Z27. Patented Nov. 2, y 24-cee?, A-6. vy

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

1.7,665. P. H. WATKNS, (UM SHEETING AND SCORING MACHINE, APPLICATION FILED MAY 28, 1920. Patented Nov. 2, 1920. 2 SHEETS-SHEET 1. Az Z B Azzee/2Z27 A 27/62//l/2éAz72s. y 24-cee?, A-6. vy-4----. P, H, WAT

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States US 20160064308A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0064308A1 YAMADA (43) Pub. Date: Mar. 3, 2016 (54) SEMICONDUCTORMODULE HOIL23/00 (2006.01) HOIL 25/8 (2006.01)

(19) United States US 20160064308A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0064308A1 YAMADA (43) Pub. Date: Mar. 3, 2016 (54) SEMICONDUCTORMODULE HOIL23/00 (2006.01) HOIL 25/8 (2006.01)

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

s /5 June 12, 1951 H. E. SPEARS ET AL 2,556,854 7 ZN NSN MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE Filed Oct 29, Saeets-Sheet 1

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0226455A1 Al-Anizi et al. US 2011 0226455A1 (43) Pub. Date: Sep. 22, 2011 (54) (75) (73) (21) (22) SLOTTED IMPINGEMENT PLATES

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0226455A1 Al-Anizi et al. US 2011 0226455A1 (43) Pub. Date: Sep. 22, 2011 (54) (75) (73) (21) (22) SLOTTED IMPINGEMENT PLATES

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1. Lee et al. (43) Pub. Date: Mar. 9, 2006

US 2006005 1222A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0051222 A1 Lee et al. (43) Pub. Date: Mar. 9, 2006 (54) MINIATURE PUMP FOR LIQUID COOLING Publication Classification

US 2006005 1222A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0051222 A1 Lee et al. (43) Pub. Date: Mar. 9, 2006 (54) MINIATURE PUMP FOR LIQUID COOLING Publication Classification

26, 5.3% gence Scott,

April 25, 1967 R. J. RADUS ETAL 3,316,514 FAIL SAFE ELECTRO-MAGNETIC LIFTING DEVICE WITH SAFETY-STOP MEANS Filed March 29, 1965 WITNESSES: F.G. 3. FG. 4. F.G. 5. NVENTORS 26, 5.3% gence Scott, 3-2%y Raymond

April 25, 1967 R. J. RADUS ETAL 3,316,514 FAIL SAFE ELECTRO-MAGNETIC LIFTING DEVICE WITH SAFETY-STOP MEANS Filed March 29, 1965 WITNESSES: F.G. 3. FG. 4. F.G. 5. NVENTORS 26, 5.3% gence Scott, 3-2%y Raymond

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

USOO582O2OOA United States Patent (19) 11 Patent Number: 5,820,200 Zubillaga et al. (45) Date of Patent: Oct. 13, 1998

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

BY 4. earea Carence A. Aroppe/ INVENTOR. Afg. 5

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0041841 A1 Huazhao et al. US 20140041841A1 (43) Pub. Date: Feb. 13, 2014 (54) (71) (72) (21) (22) (62) (30) MICRO-CHANNEL HEAT

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0041841 A1 Huazhao et al. US 20140041841A1 (43) Pub. Date: Feb. 13, 2014 (54) (71) (72) (21) (22) (62) (30) MICRO-CHANNEL HEAT

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 2014O124322A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124322 A1 Cimatti (43) Pub. Date: May 8, 2014 (54) NORMALLY CLOSED AUTOMOTIVE (52) U.S. Cl. CLUTCH WITH HYDRAULC

(19) United States US 2014O124322A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124322 A1 Cimatti (43) Pub. Date: May 8, 2014 (54) NORMALLY CLOSED AUTOMOTIVE (52) U.S. Cl. CLUTCH WITH HYDRAULC

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

March 17, 1970 H. SIGLE 3,500,75

March 17, 1970 H. SIGLE 3,500,75 WARIABLE CAPACITY FUEL NJECTION PUMP FOR FUEL COMBUSTION OPERATED PILE DRIVER Filed June 3, 1968 2. Sheets-Sheet combustion Chamber March 17, 1970 H. SIGLE 3,500,752 -

March 17, 1970 H. SIGLE 3,500,75 WARIABLE CAPACITY FUEL NJECTION PUMP FOR FUEL COMBUSTION OPERATED PILE DRIVER Filed June 3, 1968 2. Sheets-Sheet combustion Chamber March 17, 1970 H. SIGLE 3,500,752 -

(12) United States Patent (10) Patent No.: US 7,592,736 B2

US007592736 B2 (12) United States Patent (10) Patent No.: US 7,592,736 B2 Scott et al. (45) Date of Patent: Sep. 22, 2009 (54) PERMANENT MAGNET ELECTRIC (56) References Cited GENERATOR WITH ROTOR CIRCUMIFERENTIALLY

US007592736 B2 (12) United States Patent (10) Patent No.: US 7,592,736 B2 Scott et al. (45) Date of Patent: Sep. 22, 2009 (54) PERMANENT MAGNET ELECTRIC (56) References Cited GENERATOR WITH ROTOR CIRCUMIFERENTIALLY

United States Patent (19) Miller

United States Patent (19) Miller 54 LAMPHOLDER FITTING WITH THREE-WAY BRIGHTNESS SOLD-STATE FLUORESCENT LAMP BALLAST 76) Inventor: Jack V. Miller, 700 N. Auburn Ave., Sierra Madre, Calif. 91024 21 Appl.

United States Patent (19) Miller 54 LAMPHOLDER FITTING WITH THREE-WAY BRIGHTNESS SOLD-STATE FLUORESCENT LAMP BALLAST 76) Inventor: Jack V. Miller, 700 N. Auburn Ave., Sierra Madre, Calif. 91024 21 Appl.

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 2014.0034628A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0034628A1 CHEN (43) Pub. Date: Feb. 6, 2014 (54) TEMPERATURE CONTROL MODULE FOR (52) U.S. Cl. ELECTRICBLANKETS

(19) United States US 2014.0034628A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0034628A1 CHEN (43) Pub. Date: Feb. 6, 2014 (54) TEMPERATURE CONTROL MODULE FOR (52) U.S. Cl. ELECTRICBLANKETS

USOOS239155A. United States Patent (19) 11 Patent Number: 5,239,155 Olsson (45) Date of Patent: Aug. 24, 1993

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

Feb. 23, F.. rayfield 1,846,656 SINGLE STAGE COMPRESSOR. Fied Nov. 15, Sheets-Sheet. l. -1. s s. AederacA /ARa%e?ad. 27 (6.

Feb. 23, 1932. F.. rayfield 1,846,656 Fied Nov. 15, 1929 3. Sheets-Sheet. l. -1. s s AederacA /ARa%e?ad 27 (6.44% as near-sell -ress Feb. 23, 1932. F. J. RAYFIELD 1846,656 Filed Nov. 15, 1929 5. Sheets-Sheet

Feb. 23, 1932. F.. rayfield 1,846,656 Fied Nov. 15, 1929 3. Sheets-Sheet. l. -1. s s AederacA /ARa%e?ad 27 (6.44% as near-sell -ress Feb. 23, 1932. F. J. RAYFIELD 1846,656 Filed Nov. 15, 1929 5. Sheets-Sheet

United States Patent (19) Hormel et al.

United States Patent (19) Hormel et al. 54 (75) (73) 21) 22) (51) 52) (58) 56) LAMP FAILURE INDICATING CIRCUIT Inventors: Ronald F. Hormel, Mt. Clemens; Frederick O. R. Miesterfeld, Troy, both of Mich.

United States Patent (19) Hormel et al. 54 (75) (73) 21) 22) (51) 52) (58) 56) LAMP FAILURE INDICATING CIRCUIT Inventors: Ronald F. Hormel, Mt. Clemens; Frederick O. R. Miesterfeld, Troy, both of Mich.

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. Poulsen (43) Pub. Date: Oct. 25, 2012

US 20120268067A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0268067 A1 Poulsen (43) Pub. Date: (54) CHARGING STATION FOR ELECTRIC (52) U.S. Cl.... 320/109; 29/401.1 VEHICLES

US 20120268067A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0268067 A1 Poulsen (43) Pub. Date: (54) CHARGING STATION FOR ELECTRIC (52) U.S. Cl.... 320/109; 29/401.1 VEHICLES

CARBURETOR TYPE INTERNAL COMBUSTION ENGINE WITH PRECHAMBER Filed Dec. 8, a raasaara

June 4, 1963 LlEV ABRAMOVICH GoosSAK BTAL 3,092,088 CARBURETOR TYPE INTERNAL COMBUSTION ENGINE WITH PRECHAMBER Filed Dec. 8, 1959 Y S. S a raasaara s 3,092,088 3. Consequently, at the end of the suction

June 4, 1963 LlEV ABRAMOVICH GoosSAK BTAL 3,092,088 CARBURETOR TYPE INTERNAL COMBUSTION ENGINE WITH PRECHAMBER Filed Dec. 8, 1959 Y S. S a raasaara s 3,092,088 3. Consequently, at the end of the suction

United States Patent (19) Miller, Sr.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

NSN. 2%h, WD. United States Patent (19) Vranken 4,829,401. May 9, Patent Number: 45) Date of Patent: 54) ROTATING TRANSFORMER WITH FOIL

United States Patent (19) Vranken 54) ROTATING TRANSFORMER WITH FOIL WINDINGS (75) Inventor: Roger A. Vranken, Eindhoven, Netherlands (73) Assignee: U.S. Philips Corporation, New York, N.Y. (21 Appl. No.:

United States Patent (19) Vranken 54) ROTATING TRANSFORMER WITH FOIL WINDINGS (75) Inventor: Roger A. Vranken, Eindhoven, Netherlands (73) Assignee: U.S. Philips Corporation, New York, N.Y. (21 Appl. No.:

C. S. BRADLEY. ELECTRIC MOTOR. No. 439,102, Patented Oct. 28, n AA es'- Q wiza. -%%-4ge

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(12) United States Patent (10) Patent No.: US 6,975,499 B2. Takahashi et al. (45) Date of Patent: Dec. 13, 2005

USOO6975499B2 (12) United States Patent (10) Patent No.: Takahashi et al. (45) Date of Patent: Dec. 13, 2005 (54) VACUUM VARIABLE CAPACITOR WITH (56) References Cited ENERGIZATION AND HEAT SHIELDING BELLOWS

USOO6975499B2 (12) United States Patent (10) Patent No.: Takahashi et al. (45) Date of Patent: Dec. 13, 2005 (54) VACUUM VARIABLE CAPACITOR WITH (56) References Cited ENERGIZATION AND HEAT SHIELDING BELLOWS

"(2.4% May 4, 1954 C. A. GUSTAFSON 2,677,202. Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet CAR. A.

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

May 4, 1954 C. A. GUSTAFSON 2,677,202 HYDRAULIC ACTUATOR FOR OPERATING THE APRON Filed April 3, l95l AND EJECTOR OF EARTH-MOWING SCRAPERS 3. Sheets-Sheet INVENTOR, CAR. A. G2/S7AASOM/ "(2.4%. 2.-- ATTORME,

Feb. 6, R, NSSM 2,368,998

Feb. 6, 1945. R, NSSM Filed April 30, 1943 2 Sheets-Sheet 1 Feb. 6, 1945. R, NSSM Filed April 30, 1943 2. Sheets-Sheet 2 Patented Feb. 6, 1945 UNITED STATES PATENT OFFICE Raoul Nissim, London, England

Feb. 6, 1945. R, NSSM Filed April 30, 1943 2 Sheets-Sheet 1 Feb. 6, 1945. R, NSSM Filed April 30, 1943 2. Sheets-Sheet 2 Patented Feb. 6, 1945 UNITED STATES PATENT OFFICE Raoul Nissim, London, England

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

No. 801,373. PATENTED 00T, 10, J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, HEETs-SHEET. Z2562/2ZZZ Aa27/2(272, inventor

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

(12) United States Patent (10) Patent No.: US 6,205,840 B1

USOO620584OB1 (12) United States Patent (10) Patent No.: US 6,205,840 B1 Thompson (45) Date of Patent: Mar. 27, 2001 (54) TIME CLOCK BREATHALYZER 4,749,553 * 6/1988 Lopez et al.... 73/23.3 X COMBINATION

USOO620584OB1 (12) United States Patent (10) Patent No.: US 6,205,840 B1 Thompson (45) Date of Patent: Mar. 27, 2001 (54) TIME CLOCK BREATHALYZER 4,749,553 * 6/1988 Lopez et al.... 73/23.3 X COMBINATION

22-y 2 24, 7. -l- az. Z é - Jan. 26, 1971 D. F. webster 3,557,549 TURBOCHARGER SYSTEM FOR INTERNAL COMBUSTION ENGINE. is is a ST.

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 2011 0183181A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0183181 A1 M00n et al. (43) Pub. Date: Jul. 28, 2011 (54) SECONDARY BATTERY HAVING NSULATION BAG (76) Inventors:

(19) United States US 2011 0183181A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0183181 A1 M00n et al. (43) Pub. Date: Jul. 28, 2011 (54) SECONDARY BATTERY HAVING NSULATION BAG (76) Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2016/ A1

(19) United States US 2016O115854A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0115854 A1 Clever et al. (43) Pub. Date: Apr. 28, 2016 (54) ENGINE BLOCKASSEMBLY (52) U.S. Cl. CPC... F0IP3/02

(19) United States US 2016O115854A1 (12) Patent Application Publication (10) Pub. No.: US 2016/0115854 A1 Clever et al. (43) Pub. Date: Apr. 28, 2016 (54) ENGINE BLOCKASSEMBLY (52) U.S. Cl. CPC... F0IP3/02

US 8,570,835 B in a forward or aft position causing a vibratory source assembly 175 to vibrate back and forth propagating sound waves out and a

US 8,570,835 B2 21 22 in a forward or aft position causing a vibratory source assembly 175 to vibrate back and forth propagating sound waves out and around the marine vibratory source system 10. Hydraulic

US 8,570,835 B2 21 22 in a forward or aft position causing a vibratory source assembly 175 to vibrate back and forth propagating sound waves out and around the marine vibratory source system 10. Hydraulic

June 3, 1969 C. F. JACOBSON 3,448,365. RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR

June 3, 1969 C. F. JACOBSON RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR Filed Aug. 15, 1966 sheet / of 2 Area/-.' 474a2%/ June 3, 1969 - C. F. JACOBSON. RECHARGEABLE

June 3, 1969 C. F. JACOBSON RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR Filed Aug. 15, 1966 sheet / of 2 Area/-.' 474a2%/ June 3, 1969 - C. F. JACOBSON. RECHARGEABLE

Six R. Seizi. United States Patent 19 ZKK, 2.S. NSS NEG. Sayo et al. 11 4,150, Apr. 24, ELECTROMAGNETIC CLUTCH NS3NS

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

A Practical Guide to Free Energy Devices

A Practical Guide to Free Energy Devices Part PatD20: Last updated: 26th September 2006 Author: Patrick J. Kelly This patent covers a device which is claimed to have a greater output power than the input

A Practical Guide to Free Energy Devices Part PatD20: Last updated: 26th September 2006 Author: Patrick J. Kelly This patent covers a device which is claimed to have a greater output power than the input

USOO A United States Patent (19) 11 Patent Number: 6,092,999 Lilie et al. (45) Date of Patent: Jul. 25, 2000

i & RS USOO6092999A United States Patent (19) 11 Patent Number: 6,092,999 Lilie et al. (45) Date of Patent: Jul. 25, 2000 54 RECIPROCATING COMPRESSOR WITH A 4,781,546 11/1988 Curwen... 417/417 LINEAR MOTOR

i & RS USOO6092999A United States Patent (19) 11 Patent Number: 6,092,999 Lilie et al. (45) Date of Patent: Jul. 25, 2000 54 RECIPROCATING COMPRESSOR WITH A 4,781,546 11/1988 Curwen... 417/417 LINEAR MOTOR

(12) United States Patent (10) Patent No.: US 6,791,205 B2

USOO6791205B2 (12) United States Patent (10) Patent No.: Woodbridge (45) Date of Patent: Sep. 14, 2004 (54) RECIPROCATING GENERATOR WAVE 5,347,186 A 9/1994 Konotchick... 310/17 POWER BUOY 5,696,413 A 12/1997

USOO6791205B2 (12) United States Patent (10) Patent No.: Woodbridge (45) Date of Patent: Sep. 14, 2004 (54) RECIPROCATING GENERATOR WAVE 5,347,186 A 9/1994 Konotchick... 310/17 POWER BUOY 5,696,413 A 12/1997

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

United States Patent (19) Belter

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

%24- # (64%ue A7 roaways. Aé26aer 7ay Aeawaz. Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

Jan. 16, 1962 R. J. BRANDT 3,016,928 DEVICE FOR EXTRACTING FUMES FROM LIQUID FUEL STORAGE CONTAINERS Filed Jan, 19, 1959 2. Sheets-Sheet 1 t l INVENTOR. Aé26aer 7ay Aeawaz %24- # (64%ue A7 roaways. Jan.

United States Patent (19) Maloof

United States Patent (19) Maloof 11 Patent Number: 45) Date of Patent: Jul. 17, 1984 54 CART WITH SEAT AND STORAGE COMPARTMENT 76 Inventor: John J. Maloof, 20 Greenwood St., East Hartford, Conn. 06118

United States Patent (19) Maloof 11 Patent Number: 45) Date of Patent: Jul. 17, 1984 54 CART WITH SEAT AND STORAGE COMPARTMENT 76 Inventor: John J. Maloof, 20 Greenwood St., East Hartford, Conn. 06118

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080209237A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0209237 A1 KM (43) Pub. Date: (54) COMPUTER APPARATUS AND POWER SUPPLY METHOD THEREOF (75) Inventor: Dae-hyeon

(19) United States US 20080209237A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0209237 A1 KM (43) Pub. Date: (54) COMPUTER APPARATUS AND POWER SUPPLY METHOD THEREOF (75) Inventor: Dae-hyeon

3.s. isit. United States Patent (19) Momotet al. 2 Šg. 11 Patent Number: 4,709,634 (45) Date of Patent: Dec. 1, Zxx (54) (75) (73)

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

United States Patent (19) Kline et al.

United States Patent (19) Kline et al. 11 Patent Number: 45 Date of Patent: Jul. 3, 1990 54 BRAKING SYSTEMAND BREAK-AWAY BRAKNG SYSTEM 76 Inventors: Wayne K. Kline, R.D. 1, Box 340, Turbotville, Pa. 17772;

United States Patent (19) Kline et al. 11 Patent Number: 45 Date of Patent: Jul. 3, 1990 54 BRAKING SYSTEMAND BREAK-AWAY BRAKNG SYSTEM 76 Inventors: Wayne K. Kline, R.D. 1, Box 340, Turbotville, Pa. 17772;

Oct. 8, 1968 F. MELLON 3,404,927 BATTERY DISPENSER. Filed April 17, Sheets-Sheet. 2 CE. 2t c. el-n. e are. Iraverator, 7 e44 %-4-4, t/s.

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

US 7, B2. Loughrin et al. Jan. 1, (45) Date of Patent: (10) Patent No.: and/or the driven component. (12) United States Patent (54) (75)

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

(12) United States Patent

US008998577B2 (12) United States Patent Gustafson et al. (10) Patent No.: US 8,998,577 B2 (45) Date of Patent: Apr. 7, 2015 (54) (75) (73) (*) (21) (22) (65) (51) (52) TURBINE LAST STAGE FLOW PATH Inventors:

US008998577B2 (12) United States Patent Gustafson et al. (10) Patent No.: US 8,998,577 B2 (45) Date of Patent: Apr. 7, 2015 (54) (75) (73) (*) (21) (22) (65) (51) (52) TURBINE LAST STAGE FLOW PATH Inventors:

United States Patent (19) Muranishi

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

US 20080264.753A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0264753 A1 Rollion et al. (43) Pub. Date: Oct. 30, 2008 (54) FRICTIONAL CLUTCH WITH O-RING Publication Classification

US 20080264.753A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0264753 A1 Rollion et al. (43) Pub. Date: Oct. 30, 2008 (54) FRICTIONAL CLUTCH WITH O-RING Publication Classification

--- HG) F CURRENT (12) Patent Application Publication (10) Pub. No.: US 2012/ A1. f 60 HG) (19) United States MEASUREMENT

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0169284 A1 Park US 20120169284A1 (43) Pub. Date: Jul. 5, 2012 (54) (75) (73) (21) (22) (30) BATTERY CHARGING METHOD AND BATTERY

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0169284 A1 Park US 20120169284A1 (43) Pub. Date: Jul. 5, 2012 (54) (75) (73) (21) (22) (30) BATTERY CHARGING METHOD AND BATTERY

United States Patent (19) Rhodes

United States Patent (19) Rhodes 54 MODULAR RADIO CONTROL FOR USE WITH MULTIPLE TOY VEHICLES 75 73) Inventor: Assignee: Tony Rhodes, Torrance, Calif. Mattel, Inc., Hawthorne, Calif. 21 Appl. No.: 332,709

United States Patent (19) Rhodes 54 MODULAR RADIO CONTROL FOR USE WITH MULTIPLE TOY VEHICLES 75 73) Inventor: Assignee: Tony Rhodes, Torrance, Calif. Mattel, Inc., Hawthorne, Calif. 21 Appl. No.: 332,709

4 N. (12) United States Patent US 6,776,131 B2 6% 46. Aug. 17, (45) Date of Patent: (10) Patent No.: Dietz (54) INTERNAL COMBUSTION ENGINE WITH

(12) United States Patent Dietz USOO6776131B2 (10) Patent No.: (45) Date of Patent: Aug. 17, 2004 (54) INTERNAL COMBUSTION ENGINE WITH AT LEAST TWO CAMSHAFTS ARRANGED NEXT TO ONE ANOTHER AND IN EACH CASE

(12) United States Patent Dietz USOO6776131B2 (10) Patent No.: (45) Date of Patent: Aug. 17, 2004 (54) INTERNAL COMBUSTION ENGINE WITH AT LEAST TWO CAMSHAFTS ARRANGED NEXT TO ONE ANOTHER AND IN EACH CASE

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 200800301 65A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0030165 A1 Lisac (43) Pub. Date: Feb. 7, 2008 (54) METHOD AND DEVICE FOR SUPPLYING A CHARGE WITH ELECTRIC

(19) United States US 200800301 65A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0030165 A1 Lisac (43) Pub. Date: Feb. 7, 2008 (54) METHOD AND DEVICE FOR SUPPLYING A CHARGE WITH ELECTRIC

HHRH. United States Patent (19) Lissaman et al. (11) Patent Number: 5,082,079 (45) Date of Patent: Jan. 21, 1992 (51) (54) (75) (73)

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

(12) United States Patent

USOO861 8656B2 (12) United States Patent Oh et al. (54) FLEXIBLE SEMICONDUCTOR PACKAGE APPARATUS HAVING ARESPONSIVE BENDABLE CONDUCTIVE WIRE MEMBER AND A MANUFACTURING THE SAME (75) Inventors: Tac Keun.

USOO861 8656B2 (12) United States Patent Oh et al. (54) FLEXIBLE SEMICONDUCTOR PACKAGE APPARATUS HAVING ARESPONSIVE BENDABLE CONDUCTIVE WIRE MEMBER AND A MANUFACTURING THE SAME (75) Inventors: Tac Keun.

NZ 8 SS 10 INSULATED ELECTRICTERMINAL. United States Patent Iantorno et al. ' (15) 3,671,920 (45) June 20, 1972 ASSEMBLY

United States Patent Iantorno et al. (54) 72 73) 22) 21 ) 52 51 58) (56) INSULATED ELECTRICTERMINAL ASSEMBLY Inventors: James F. antorno, Mamaroneck; John Wagner, Pleasantville; Stephen J. Schu macher,

United States Patent Iantorno et al. (54) 72 73) 22) 21 ) 52 51 58) (56) INSULATED ELECTRICTERMINAL ASSEMBLY Inventors: James F. antorno, Mamaroneck; John Wagner, Pleasantville; Stephen J. Schu macher,

April 5, G, E, SWANSON 2,113,007 CYLINDER LOCK. NS: S.S.S.S.S Né EEE SS W. a. <SNSSSSSSSS/fde. is E( 4 NN. p7 NSN NNNN N&zo 76 v7 /6 2/23 / NS

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

III If 2-1. Feb. 3, 1959 % ,871, as 55 E. 2. Filed Jan. 28, 1957 JOHN E HEWS0N J. E. HEWSON INVENTOR, ATTORNEY WALWE MANIFOLD

Feb. 3, 199 Filed Jan. 8, 197 J. E. HEWSON WALWE MANIFOLD,871,881 Sheets-Sheet l E=== D E. FEF, III If -1. FE %3- - as N & INVENTOR, JOHN E HEWS0N ATTORNEY Feb. 3, 199 J. E. HEWSON,871,881 go 4 3 a is

Feb. 3, 199 Filed Jan. 8, 197 J. E. HEWSON WALWE MANIFOLD,871,881 Sheets-Sheet l E=== D E. FEF, III If -1. FE %3- - as N & INVENTOR, JOHN E HEWS0N ATTORNEY Feb. 3, 199 J. E. HEWSON,871,881 go 4 3 a is

3,114,326 12/1963 Yaindi... 62/55 3,206,110 9/1965 Waibel /567 3,260,217 7/1966 Thresher /569

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

od f 11 (12) United States Patent US 7,080,599 B2 Taylor Jul. 25, 2006 (45) Date of Patent: (10) Patent No.:

US007080599B2 (12) United States Patent Taylor (10) Patent No.: (45) Date of Patent: Jul. 25, 2006 (54) RAILROAD HOPPER CAR TRANSVERSE DOOR ACTUATING MECHANISM (76) Inventor: Fred J. Taylor, 6485 Rogers

US007080599B2 (12) United States Patent Taylor (10) Patent No.: (45) Date of Patent: Jul. 25, 2006 (54) RAILROAD HOPPER CAR TRANSVERSE DOOR ACTUATING MECHANISM (76) Inventor: Fred J. Taylor, 6485 Rogers

April 2, 1968 A. L. NASVYTIs 3,375,739 CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, Sheets-Sheet l N. N S

April 2, 1968 A. L. NASVYTIs CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, 1966 3 Sheets-Sheet l st SS N. N S A. N S INVENTOR. 167/raas Z. Maszy/7s -3% 1%-1. 72e-este, "4e 71-16tz,ORNEYS April

April 2, 1968 A. L. NASVYTIs CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, 1966 3 Sheets-Sheet l st SS N. N S A. N S INVENTOR. 167/raas Z. Maszy/7s -3% 1%-1. 72e-este, "4e 71-16tz,ORNEYS April

30 Foreign Application Priority Data Oct. 17, 1975 (CH) Switzerland /75 51 Int. C... F04B 17/00 52 U.S.C /409; 415/69; 417/360.

United States Patent 19 Curiel et al. 54 TWO-STAGE EXHAUST-GAS TURBOCHARGER (75) Inventors: Georges Curiel, Wettingen; Ulrich Linsi, Zurich, both of Switzerland 73) Assignee: BBC Brown Boveri & Company

United States Patent 19 Curiel et al. 54 TWO-STAGE EXHAUST-GAS TURBOCHARGER (75) Inventors: Georges Curiel, Wettingen; Ulrich Linsi, Zurich, both of Switzerland 73) Assignee: BBC Brown Boveri & Company

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 3-vi-ucvtot 21, 6)) 7/4-ee-d

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

NES. sis. & ASN. 27, 2 to 2 E. // United States Patent (19) Kress 4,250,658. Feb. 17, ered by a conventional model piston engine.

United States Patent (19) Kress (11) 45) 4,250,658 Feb. 17, 1981 (54) 76) (21) 22) 63) (51) (52) 58) 56 DUCTED FAN FOR MODEL AIRCRAFT Inventor: Robert W. Kress, 27 Mill Rd., Lloyd Harbor, N.Y. 11746 Appl.

United States Patent (19) Kress (11) 45) 4,250,658 Feb. 17, 1981 (54) 76) (21) 22) 63) (51) (52) 58) 56 DUCTED FAN FOR MODEL AIRCRAFT Inventor: Robert W. Kress, 27 Mill Rd., Lloyd Harbor, N.Y. 11746 Appl.

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0193696A1 Kim US 201401.93696A1 (43) Pub. Date: Jul. 10, 2014 (54) (71) (72) (73) (21) (22) (30) SECONDARY BATTERY AND SECONDARY

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2014/0193696A1 Kim US 201401.93696A1 (43) Pub. Date: Jul. 10, 2014 (54) (71) (72) (73) (21) (22) (30) SECONDARY BATTERY AND SECONDARY

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 2012O240592A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0240592 A1 Keny et al. (43) Pub. Date: Sep. 27, 2012 (54) COMBUSTOR WITH FUEL NOZZLE LINER HAVING CHEVRON