26, 5.3% gence Scott,

|

|

|

- Esther Randall

- 5 years ago

- Views:

Transcription

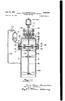

1 April 25, 1967 R. J. RADUS ETAL 3,316,514 FAIL SAFE ELECTRO-MAGNETIC LIFTING DEVICE WITH SAFETY-STOP MEANS Filed March 29, 1965 WITNESSES: F.G. 3. FG. 4. F.G. 5. NVENTORS 26, 5.3% gence Scott, 3-2%y Raymond J. Radus and Lowrence R. Scott 6-cCOll ATTORNEY

2 United States Patent Office 3,316,514 Patented Apr. 25, ,316,514 FAIL SAFE ELECTRO.MAGNETIC LIFTNG DE VCE WITH SAFETY-STOP MEANS Raymond J. Radus, Monroeville, and Lawrence R. Scott, Pittsburgh, Pa., assignors to Westinghouse Electric Cor poration, Pittsburgh, Pa., a corporation of Pennsylvania Filed Mar. 29, 1965, Ser. No. 443,331 4 Claims. (C ) The present invention relates to lifting apparatus, and more particularly to lifting apparatus of the permanent magnet type. Lifting or hoist apparatus utilizing electro-magnets have been in operation for many years. The electro magnet type of lifting apparatus has two severe dis advantages: (1) a large amount of energy must be supplied to the electro-magnet in order to generate a sufficient magnetic field to provide reasonable lifting weight capacity, and (2) the load will fall if the electro magnet is deemergized due to a power failure or other interruption of electrical power to a coil of the electro magnet. The latter disadvantage makes such apparatus dangerous or requires additional safety features to insure the load will not accidentally be dropped. The use of a permanent magnet for the lifting apparatus would be particularly advantageous from an energy standpoint. However, the difficulty of disengaging the load from the permanent magnet must be overcome. Also, safety must be considered if the permanent magnet is to be made fail safe. In copending applications, Ser. No. 167,360, filed Jan. 19, 1962, entitled, Magnetic Memory Device, and Ser. No. 283,035, filed May 24, 1963, entitled, Permanent Magnet Memory Device. Using Pulse Control, both by Raymond J. Radus and assigned to the same assignee as the present application, permanent magnet devices are shown in which the attractive magnetic force of a perma nent magnet may be bistably switched between different magnetic circuits of the device. The switching between the high and low attractive force circuits of the memory device is accomplished by the application of a low energy electrical signal to an electro-magnetic coil disposed in one or more of the magnetic circuits. The device will remain in one of its bistable states until a control signal is applied to switch another of the magnetic circuits to a higher or lower reluctance than the reference magnetic circuit. Lifting apparatus which could incorporate such a device would be highly advantageous in that the device requires only the momentary use of a very low energy source which is used only for switching. Moreover, if a hoist using permanent magnet devices can be made fail safe such lifting apparatus would overcome both of the serious problems encountered in the electro-magnetic type of lifting apparatus. It is, therefore, an object of the present invention to provide new and improved lifting apparatus utilizing permanent magnet devices. It is a further object of the present invention to provide new and improved lifting apparatus utilizing permanent magnet memory devices in which the engaging or dis engaging of a load may be accomplished by a low level energy source. It is a still further object of the present invention to provide new and improved lifting apparatus utilizing permanent magnet memory devices and which incor porates therein a fail safe feature prohibiting the acci dental dropping of a load once engaged. Broadly, the present invention provides lifting apparatus in which a permanent magnet device is provided wherein a high attractive force may be switched from one mag netic circuit of the device to another magnetic circuit of the device through the use of a control winding. When lifting is desired, the high attractive magnetic force is Switched to the end of the device adjacent the load to be lifted. Safety means are provided to prevent the acci dental dropping of the load during the moving operation. These and other objects and advantages of the present invention will become more apparent when considered in view of the following specification and drawings, in which: FIGURE 1 is a pictorial diagram of the lifting ap paratus of the present invention; and FIGS. 2, 3, 4 and 5 are front elevation views of the present lifting apparatus and are used in the explanation of the operation thereof. Referring to FIG. 1, lifting apparatus is shown in cluding magnetic memory devices. Only two magnetic memory devices are shown although it should be noted that a larger or smaller number of such devices could be employed. One device comprises a permanent magnet 10 disposed between a pair of substantially planar pole pieces 12 and 14 adjacent respectively the North and the South poles of the permanent magnet 10. The other permanent magnet device is similar and includes a perma nent magnet 16 sandwiched between a pole piece 18 dis posed adjacent the South pole of the permanent magnet 16 and a pole piece 20 disposed adjacent the North pole. A control winding 22 having input terminals 24 and 26 is disposed about the center pole members 14 and 18. Additional control windings could be added of course if desired at different positions if convenient for design purposes. The permanent magnets 10 and 16 may, for example, be the well known ceramic type. The pole piece members 12, 14, 18 and 20 may comprise a soft magnetic material. The magnetic device has two ends at which magnetically attractive forces will develop. These ends will be termed a load end 28 and a keeper end 30. At the load end 28, the pole members 12, 4, 18 and 20 are shown tapered to concentrate the magnetic force. The permanent magnets and pole members are secured to gether by any convenient means. A load 32 which may comprise any magnetically attrac tive material such as iron or steel is shown disposed adjacent the load end 28 of the magnetic devices. A keeper member 34 is disposed adjacent the keeper end 30 of the magnetic devices. The keeper member 34 may comprise a soft magnetic material similar to those of the pole members. A lifting loop. 36 is secured to the keeper member 34, for example, by welding. A lifting hook may thus be inserted in the lifting loop 36 and be utilized in conjunction with an external hoist to move and position the lifting apparatus. - A pair of safety members 38 and 40 having an L-shape are secured to the pole pieces 12 and 20 at their external surfaces. The safety members 38 and 40 may be secured to the pole members 2 and 20 respectively by welding, boiting or other convenient methods. The safety mem bers comprise a non-magnetic material, for example, brass or non-magnetic stainless steel. A stop portion 42 and 44 which extends over a portion of the keeper member 34 is provided in the safety members 38 and 49. Thus, when the keeper member 34 is lifted vertically it will move a distance away from the keeper end 30 of the mag netic devices and then will engage the stop portions 42 and 44 of the safety members 38 and 40. Other means of securing the safety members to the permanent magnet devices could of course be employed. In the condition shown in FIG. 1, the lifting apparatus is being positioned over the load 32 and is at the instant pictured a distance G1 away from the load end 28. The distance G will be termed the load air gap which will have a minimum value when the load end 28 abuts against the surface of the load 32. The keeper member 34 is shown abutting against the top surface 30 so that

3 3,316, an air gap G exists therebetween. When the keeper fer back and forth between the keeper and load mag member 34 and the end portion 30 are abutting, a mini netic circuits. mum keeper air gap exists. When the keeper 34 is When a mechanically lifting force is applied to the separated from the end 30 and abuts against the stop por lifting loop 36 to move the keeper member 34 vertically, tions 42 and 44, a maximum keeper air gap will exist. the keeper member 34 will move until its top portion A load magnetic circuit is established from the North engages the stop portions 42 and 44 of the safety mem poles of the permanent magnets 10 and 16, through the bers 38 and 40. At this point, the air gap G is at a pole members 12 and 20, the air gap G1, the load 32, the maximum. Several advantages result from having maxi air gap G, the center pole members 14 and 18, to the mum and minimum air gap positions for the keeper 34 South pole of the permanent magnets. A magnetic flux 10 with respect to the end 30 of the permanent magnet de B will flow through the load magnetic circuit. vices. One of the advantages of the variable air gap is A keeper magnetic circuit is established with a mag that when maximum keeper air gap exists, that is, when netic flux B flowing from the North poles of the per the load is being lifted, a high magnitude lifting force manent magnets 10 and 16, through the outer pole mem will appear at the lifting end 28 of the permanent mag bers 12 and 20 in the opposite direction to the magnetic 5 net devices since the load magnetic circuit is of a very flux B, through the air gap G, the keeper member 34, low reluctance in comparison to the keeper magnetic cir the air gap B, and back to the South poles of the cuit having the maximum keeper air gaps G. Thus, a permanent magnets 10 and 16 through the center pole larger attractive force is developed to attract the load 32 members 14 and 18 in the opposite direction to the mag than otherwise would be provided if the keeper air gap netic flux B. The magnitude of the attractive force ap 20 were constant which has the obvious advantage of per plied to the load 32 or the keeper 34 will depend upon mitting larger loads to be moved. Also, as shown in the amount of magnetic flux B1 or B passing through FIG. 1, the permanent magnets 10 and 16 may be posi their respective magnetic circuits. tioned closer to the load end than the keeper end in Assume initially that the keeper member 34 is placed order to increase the attractive force at the load end. adjacent the end 30 of the magnetic device so that there Another advantage of having a variable keeper air gap is a minimum keeper air gap G, and that the load 32 Gk is that minimum control power is only required to is separated from the end 28. The majority of the mag Switch the high attractive forces between the load and netic flux provided by the permanent magnets will align the keeper and vice versa when the air gap G is at a itself into the keeper circuit so that the keeper 34 will minimum. This may be seen since when the keeper 34 be held by a relatively strong magnetic force to the end 30 is adjacent the end 30 a relatively low reluctance path is 30. With the lifting apparatus in the state shown, the provided, and, therefore, a relatively low intensity input apparatus may be positioned over the load 32 and may signal applied to the coil 22 will have a greater effect in be lowered to abut against the top surface of the load. either aiding or opposing the permanent magnet flux B. Since the majority of the magnetic flux had previously in the keeper circuit. Thus, during the positioning opera been aligned in the keeper circuit including the keeper tion when the keeper magnetic circuit is in its low re member 34, the keeper member will be held against the luctance state and adjacent the end 30, when the per end 30 of the device still with a relatively high attractive manent magnet devices are disposed over the load 32, force while the load 32 will only be held to the end 28 a low intensity control signal applied to the control wind with a relatively small attractive force as determined by ing 22 in a direction to oppose the keeper flux B will the amount of flux B which will pass therethrough. The 40 readily switch the low reluctance path to that including mechanism by which the flux alignment takes place is the load 32 so that the load may be lifted. Alternately, discussed in full detail in the above copending applica when the moving operation is over and it is desired to tions which are incorporated by reference herein. disengage the load, with the keeper 34 having been In order to switch the high attractive force from the lowered to be adjacent the keeper end 30 at minimum keeper 34 to the load 32 so that the load may be lifted, 45 keeper air gap Gk, a low intensity control signal in the it is necessary that a majority of the flux supplied by opposite direction to the previous signal in a direction to the permanent magnets 10 and 16 be realigned to pass induce a flux which will aid the keeper flux B will through the load 32 rather than the keeper 34. This may readily permit the flux supplied by the permanent mag be accomplished by applying a control signal momentarily nets 10 and 16 to switch from the load 32 to the keeper to the control winding 22 through the terminals 24 and ; 34 and thereby permit the load to be disengaged from 26. The control signal may be a unidirectional low in the lifting apparatus. The lifting apparatus may then be tensity signal applied in such a direction as to oppose moved to other areas with the keeper 34 being held the flux B flowing in the pole pieces 14 and 18. The against the end 36 by a relatively strong attractive force. induced flux caused by the coil 22 in bucking the flux from Still another advantage of the variable keeper air gap the permanent magnet will thereby increase the reluctance is that when the keeper air gap is at a maximum value of the keeper magnetic circuit. The keeper magnetic cir during the lifting operation with the keeper member 34 cuit having an increased reluctance will cause a large adjacent the stop portions 42 and 44, the accidental application of switching signals to the coil 22 will not percentage of the flux from the permanent magnets 10 drop the load. Normally, if keeper 34 were abutting and 16 to be transferred from the keeper magnetic cir 60 the end 30, the load would drop since the high attractive cuit to the load magnetic circuit. This flux transferral force would be transferred from the load to the keeper. will thereby switch the high attractive force to the load However, with a maximum air gap G existing during end 28 of the permanent magnet device so that the load the lifting operation when the load is carried above sur member 32 will be held thereto with a high attractive face level, the normal low intensity switching signal force. The load 32 will now be held by a high attractive 65 will not be of sufficient strength to effect the transfer force while the keeper member 34 is free to move ver of flux from the load circuit to the keeper circuit. The tically if a mechanical force is applied thereto. It should maximum keeper air gap G can be so designed to set be noted that all that was required to switch the lifting in a safety factor to insure that even an accidental sig apparatus from a no lift to lift state was the application nal applied to the control winding 22 of several times of a low energy D.C. signal to the control signal which 70 the normal necessary switching magnitude at minimum may be supplied by a low voltage battery. It should also air gap G will not be effective to transfer the strong be observed that the control pulse need only be momen attractive force from the load to the keeper and thereby tarily applied to the control windings and then may be drop the load. It can thus be seen that a fail safe type disconnected therefrom. The momentary application of of lifting apparatus is provided by the apparatus shown the control signal is effective to accomplish the flux trans 75 in FIG. 1.

4 5 In FIGS. 2, 3, 4 and 5, a sequence of the lifting and disengaging operations are shown. In FIG. 2, the lift ing apparatus is being lowered over a load 32 resting on a surface. The keeper member 34 is held by a rela tively strong attractive force, that is, one at least suffi ciently strong to permit the keeper 34 to remain ad jacent the keeper end 30 of the permanent magnet de vices while the lifting apparatus is being positioned over a load. Under these conditions, a majority of the flux from the permanent magnets 10 and 16 pass through the keeper magnetic circuit. The lifting apparatus is shown disposed over the load 32 in FIG. 3. By the applica tion of a D.C. control signal, for example, from a bat tery to the winding 22, a majority of the flux from the permanent magnets is transferred from the keeper mag netic circuit to the load magnetic circuit. Such a trans fer of flux may be effected by the application of a low intensive voltage of a polarity as shown on the diagram which will oppose the flux in the keeper magnetic circuit and therefore increase the reluctance thereof so that a majority of the flux may realign itself to pass through the load 32. A high attractive force having the ca pability of lifting the load 32 will thus be applied at the end 28 adjacent the load 32. In FIG. 4, the lifting apparatus is shown lifting the load 32 above the surface level. At this point, the keeper member 34 has moved away from the keeper end 30 of the magnetic devices since only a relatively small at tractive force is applied at that end. By the applica tion of mechanical force through the lifting loop 36 on 30 the keeper member 34, the keeper will move away from the end 30 until it engages the stop portions 42 and 44 of the non-magnetic safety members 38 and 40. When the keeper member 34 abuts against stop members 42 and 44, a maximum attractive force is developed at the end of the permanent magnet devices to strongly hold the load by a strong attractive force thereto. Also at this maximum air gap position, the accidental applica tion of a control signal that would normally switch the flux back to the keeper member will not be effective 40 because of the maximum air gap. Therefore, the load cannot be dropped by the application of a control sig nal accidentally to the coil 22. Hence, the device is fail safe. The load 32 is shown having been moved and ready for disengagement in FIG. 5 after the load 32 has been brought to surface level. The keeper member 34 then drops from its maximum air gap position to its minimum air gap position abutting against the end 30 of the per manent magnet devices. At the minimum keeper air gap position G, the application of a low intensity con trol signal of the polarity as shown in FIG. 5 will in duce a flux to aid the flux through the keeper magnetic circuit and thereby reduce its reluctance to a level lower than that of the load 32. A majority of the flux from the permanent magnets 10 and 16 will align themselves to pass through the keeper circuit now causing a rela tively high attractive force to be transferred from the load 32 to the keeper 34. In this condition, the lifting apparatus may be disengaged from the load and moved to other load positions, with the pickup and dropping operations being repeated. Although the present invention has been described with a certain degree of particularity, it should be understood that the present disclosure has been made only by way of example and that numerous changes in details of con struction and combination and arrangement of parts and elements may be resorted to without departing from the scope and spirit of the present invention. We claim as our invention: 1. In magnetic lifting apparatus for moving magnetic loads and being operative with control signals, the com bination of: a permanent magnet device including a permanent magnet for supplying magnetic flux, a pair of pole members, said permanent magnet being dis 3,316, O 5 6 posed between said pair of pole members for providing first and a second magnetic circuit respectively through a load and a keeper end of said device, and a control winding disposed in at least one of said magnetic cir cuits for controlling the attractive force at said load and keeper ends of said device in response to control signals being applied thereto; a non-magnetic safety mem ber connected to said pole pieces and having a stop por tion thereon; a keeper member disposed at said keeper end of said magnetic device between said device and the stop portion of said safety member in said first magnetic circuit, said load being movable by disposing said keeper member adjacent said keeper end of said device and dis posing said load adjacent said load end thereof in said second magnetic circuit and by applying a control sig nal to said control winding to transfer a strong at tractive force to said second magnetic circuit so that said load is held to said magnet device at said load end thereof by a strong attractive force, said keeper mem ber moving away from said keeper end of said magnetic device until engaging the stop portion of said safety member so that the inadvertent application of a control signal to said control winding will not drop said load. 2. In lifting apparatus for moving loads the combina tion of: a permanent magnet device including a perma nent magnet for supplying magnetic flux, a pair of pole members, said permanent magnet being disposed between said pair of pole members for providing at least two magnetic circuits respectively through a load and a keeper end of said device, and a control winding disposed in at least one of said magnetic circuits for controlling the attractive force at said load and keeper ends of said device in response to control signals being applied there to; a safety member secured to said magnet device and having a stop portion thereon; said load disposed for moving at said load end of said magnet device in one of said magnetic circuits; a keeper member disposed at said keeper end of said magnetic device, said load being movable by applying a control signal to said con trol winding to transfer a strong attractive force to the magnetic circuit including said load, said keeper mem ber moving away from said keeper end of said mag net device until engaging the stop portion of said safety member so that the inadvertent application of a control signal to said control winding will not transfer the strong attractive force away from said load. 3. In magnetic lifting apparatus for moving magnetic loads and being operative with a source of control sig nais, the combination of: a permanent magnetic flux transfer device including a permanent magnet for supply ing magnetic flux, a pair of pole members, said per manent magnet being disposed between said pair of pole members for providing a first and a second magnetic circuit respectively through a load and a keeper end of said device, with the magnetic flux dividing between said magnetic circuits according to their relative reluctance, and a control winding disposed in at least one of said magnetic circuits for controlling the reluctance thereof in response to control signals being applied thereto; said load disposed for moving at said load end of said mag netic device in said first magnetic circuit with a load air gap being formed between said load and said pole pieces at said load end of said device; a keeper member movably disposed at said keeper end of said magnetic device, with a keeper air gap being formed between said keeper member and the pole pieces at said keeper end of said device; and safety means connected to said de vice to prevent the inadvertent dropping of said load; said apparatus operative for moving said load by disposing said load and said keeper members adjacent said load and keeper ends of said device respectively so that said load and keeper air gaps are a minimum and by apply ing a control signal to said control winding to transfer a majority of the magnetic flux to said first magnetic circuit with said load being held to said magnet device

5 3,316, the stop portion of said lifting member with a keeper by a strong attractive force, said load being movable by the application of mechanical force to said keeper air gap being formed between said keeper member and the pole pieces at said keeper end of said magnetic de member so that said keeper member moves away from said keeper end of said magnetic device until being re vice; said apparatus operative for moving said load by stricted by said safety means, said keeper air gap being disposing said load and said keeper member adjacent said load and keeper ends respectively of said device so a maximum when said keeper member is restricted by said safety means so that the inadvertent application of that said load and keeper air gaps are a minimum and a control signal to said control winding will not transfer by applying a control signal to said control winding to sufficient flux to said keeper member to drop said load. transfer a majority of the magnetic flux to said first mag 4. In magnetic lifting apparatus for moving magnetic IO netic circuit with said load being held to said load end loads and being operative with control signals, the com of said magnet device by a strong attractive force, said load bination of: a permanent magnetic flux transfer device being movable by the application of mechanical force including a permanent magnet for supplying magnetic to said keeper member so that said keeper member moves flux, a pair of pole members, said permanent magnet away from said keeper end of said magnetic device until disposed between a pair of pole members for providing a 15 engaging the stop portion of said safety member, said first and a second magnetic circuit through a load and a keeper end of said device, with the magnetic flux dividing between said magnetic circuits according to their relative reluctance, and a control winding disposed in at least one of said magnetic circuits for controlling the reluctance thereof in response to control signals being applied thereto; a non-magnetic safety member secured to said pair of pole pieces of said magnetic device and having a stop portion thereon; said load disposed for moving at said load end of said magnetic device in said first magnetic circuit with a load air gap being formed between said load and said pole pieces at said load end of said device; a keeper member disposed at said keeper end of said magnetic device between said device and keeper air gap being a maximum when said keeper mem ber engages said stop portion so that the inadvertent application of a control signal to said control winding will not transfer sufficient flux to said keeper member to drop said load. References Cited by the Examiner UNITED STATES PATENTS 5/1963 Cotton de Bennetot X 8/1964 Moreau X 3,089,064 3,146,381 BERNARDA. GILHEANY, Primary Examiner. H. A. LEWITTER, Assistant Examiner.

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

A Practical Guide to Free Energy Devices

A Practical Guide to Free Energy Devices Part PatD20: Last updated: 26th September 2006 Author: Patrick J. Kelly This patent covers a device which is claimed to have a greater output power than the input

A Practical Guide to Free Energy Devices Part PatD20: Last updated: 26th September 2006 Author: Patrick J. Kelly This patent covers a device which is claimed to have a greater output power than the input

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1

(19) United States US 2010O225192A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0225192 A1 Jeung (43) Pub. Date: Sep. 9, 2010 (54) PRINTED CIRCUIT BOARD AND METHOD Publication Classification

(19) United States US 2010O225192A1 (12) Patent Application Publication (10) Pub. No.: US 2010/0225192 A1 Jeung (43) Pub. Date: Sep. 9, 2010 (54) PRINTED CIRCUIT BOARD AND METHOD Publication Classification

Oct. 8, 1968 F. MELLON 3,404,927 BATTERY DISPENSER. Filed April 17, Sheets-Sheet. 2 CE. 2t c. el-n. e are. Iraverator, 7 e44 %-4-4, t/s.

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

22-y 2 24, 7. -l- az. Z é - Jan. 26, 1971 D. F. webster 3,557,549 TURBOCHARGER SYSTEM FOR INTERNAL COMBUSTION ENGINE. is is a ST.

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

s /5 June 12, 1951 H. E. SPEARS ET AL 2,556,854 7 ZN NSN MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE Filed Oct 29, Saeets-Sheet 1

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

April 24, 1951 LE ROY S. schell, JR 2,550,500

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

(12) United States Patent

(12) United States Patent US009277323B2 (10) Patent No.: L0cke et al. (45) Date of Patent: Mar. 1, 2016 (54) COMPACT AUDIO SPEAKER (56) References Cited (71) Applicant: Apple Inc., Cupertino, CA (US) U.S.

(12) United States Patent US009277323B2 (10) Patent No.: L0cke et al. (45) Date of Patent: Mar. 1, 2016 (54) COMPACT AUDIO SPEAKER (56) References Cited (71) Applicant: Apple Inc., Cupertino, CA (US) U.S.

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

Feb. 25, 1958 B. CAMETTI ET AL 2,824,983 ELECTRIC MOTOR COOLING Filed Nov. 2, 1954 2 Sheets-Sheet l Fig. 3. NVENTOR Benjamin Cametti 8 William M. Wepfer. -1,3-al ATTORNEY Feb. 25, 1958 B. CAMETTI ETAL

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1. Lee et al. (43) Pub. Date: Mar. 9, 2006

US 2006005 1222A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0051222 A1 Lee et al. (43) Pub. Date: Mar. 9, 2006 (54) MINIATURE PUMP FOR LIQUID COOLING Publication Classification

US 2006005 1222A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0051222 A1 Lee et al. (43) Pub. Date: Mar. 9, 2006 (54) MINIATURE PUMP FOR LIQUID COOLING Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

April 2, 1968 A. L. NASVYTIs 3,375,739 CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, Sheets-Sheet l N. N S

April 2, 1968 A. L. NASVYTIs CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, 1966 3 Sheets-Sheet l st SS N. N S A. N S INVENTOR. 167/raas Z. Maszy/7s -3% 1%-1. 72e-este, "4e 71-16tz,ORNEYS April

April 2, 1968 A. L. NASVYTIs CONICAL, PLANETARY FRICTION GEAR DRIVE Filed Feb. 17, 1966 3 Sheets-Sheet l st SS N. N S A. N S INVENTOR. 167/raas Z. Maszy/7s -3% 1%-1. 72e-este, "4e 71-16tz,ORNEYS April

III IIII. United States Patent (19) Spencer et al. DISPLAY. Appl. No.: 493,622. Primary Examiner-Richard Chilcot

United States Patent (19) Spencer et al. (54) (75) (73) 21) 22 (51) 52 (58) 56 ELECTROMAGNETC FLOW METER Inventors: Jordan L. Spencer; David C. Rodgers, both of Tenafly, N.J. Assignee: The Trustees of

United States Patent (19) Spencer et al. (54) (75) (73) 21) 22 (51) 52 (58) 56 ELECTROMAGNETC FLOW METER Inventors: Jordan L. Spencer; David C. Rodgers, both of Tenafly, N.J. Assignee: The Trustees of

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

(12) United States Patent (10) Patent No.: US 6,205,840 B1

USOO620584OB1 (12) United States Patent (10) Patent No.: US 6,205,840 B1 Thompson (45) Date of Patent: Mar. 27, 2001 (54) TIME CLOCK BREATHALYZER 4,749,553 * 6/1988 Lopez et al.... 73/23.3 X COMBINATION

USOO620584OB1 (12) United States Patent (10) Patent No.: US 6,205,840 B1 Thompson (45) Date of Patent: Mar. 27, 2001 (54) TIME CLOCK BREATHALYZER 4,749,553 * 6/1988 Lopez et al.... 73/23.3 X COMBINATION

Jan. 14, ,421,236. Filed June 22, E, U, MOYER ATTORNEYS LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

(19) United States US 2011 0121100A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0121100 A1 Feenstra (43) Pub. Date: May 26, 2011 (54) COVER FOR PROTECTINGA FUSIBLE Publication Classification

(19) United States US 2011 0121100A1 (12) Patent Application Publication (10) Pub. No.: US 2011/0121100 A1 Feenstra (43) Pub. Date: May 26, 2011 (54) COVER FOR PROTECTINGA FUSIBLE Publication Classification

(12) United States Patent (10) Patent No.: US 7,592,736 B2

US007592736 B2 (12) United States Patent (10) Patent No.: US 7,592,736 B2 Scott et al. (45) Date of Patent: Sep. 22, 2009 (54) PERMANENT MAGNET ELECTRIC (56) References Cited GENERATOR WITH ROTOR CIRCUMIFERENTIALLY

US007592736 B2 (12) United States Patent (10) Patent No.: US 7,592,736 B2 Scott et al. (45) Date of Patent: Sep. 22, 2009 (54) PERMANENT MAGNET ELECTRIC (56) References Cited GENERATOR WITH ROTOR CIRCUMIFERENTIALLY

(12) United States Patent (10) Patent No.: US B1

USOO7628442B1 (12) United States Patent (10) Patent No.: Spencer et al. (45) Date of Patent: Dec. 8, 2009 (54) QUICK RELEASE CLAMP FOR TONNEAU (58) Field of Classification Search... 296/100.04, COVER 296/100.07,

USOO7628442B1 (12) United States Patent (10) Patent No.: Spencer et al. (45) Date of Patent: Dec. 8, 2009 (54) QUICK RELEASE CLAMP FOR TONNEAU (58) Field of Classification Search... 296/100.04, COVER 296/100.07,

310/227, 228 Attorney, Agent, or Firm-Head, Johnson & Kachigian

US005742111A United States Patent (19) 11 Patent Number: Reed 45 Date of Patent: Apr. 21, 1998 54 D.C. ELECTRIC MOTOR 4,930,210 6/1990 Wang... 29/597 5,001,375 3/1991 Jones... 310/68 75) Inventor: Troy

US005742111A United States Patent (19) 11 Patent Number: Reed 45 Date of Patent: Apr. 21, 1998 54 D.C. ELECTRIC MOTOR 4,930,210 6/1990 Wang... 29/597 5,001,375 3/1991 Jones... 310/68 75) Inventor: Troy

United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989

![United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989](/thumbs/80/81257393.jpg) United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 54 MAGNETICFORCE GENERATING 56 References Cited METHOD AND APPARATUS U.S. PATENT DOCUMENTS 4,074,153 2/1978

United States Patent 19 [11] Patent Number: 4,877,983 Johnson (45) Date of Patent: Oct 31, 1989 54 MAGNETICFORCE GENERATING 56 References Cited METHOD AND APPARATUS U.S. PATENT DOCUMENTS 4,074,153 2/1978

No. 476,983. Patented June 14 l892. 7/71

(No Model.) T. A. EDISON, PYROMAGNETIC GENERATOR, No.. Patented June 14 l892. 7/71 HIH 7W H. 2III, listin III. It UNITED STATES PATENT OFFICE. THOMAS A. EDISON, OF LLEWELLYN PARK, NEW JERSEY. PYRO MAGNET

(No Model.) T. A. EDISON, PYROMAGNETIC GENERATOR, No.. Patented June 14 l892. 7/71 HIH 7W H. 2III, listin III. It UNITED STATES PATENT OFFICE. THOMAS A. EDISON, OF LLEWELLYN PARK, NEW JERSEY. PYRO MAGNET

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

United States Patent (19) 11 Patent Number: 4924,123. Hamajima et al. 45 Date of Patent: May 8, 1990

United States Patent (19) 11 Patent Number: 4924,123 Hamajima et al. 45 Date of Patent: May 8, 1990 54) LINEAR GENERATOR 4,454,426 6/1984 Benson... 290/1 R s 8 8 4,500,827 2/1985 Merritt et al.... 322/3

United States Patent (19) 11 Patent Number: 4924,123 Hamajima et al. 45 Date of Patent: May 8, 1990 54) LINEAR GENERATOR 4,454,426 6/1984 Benson... 290/1 R s 8 8 4,500,827 2/1985 Merritt et al.... 322/3

United States Patent 19

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

III IIII. United States Patent (19) Berdut 5,452,663. Sep. 26, Patent Number: 45) Date of Patent:

United States Patent (19) Berdut 54) LEVITATION AND PROPULSION SYSTEM USING PERMANENT MAGNETS AND INTERLEAVED RON OR STEEL 76 Inventor: Elberto Berdut, Orquidea No. 98, Santa Maria, Santa Mario, Guaynabo,

United States Patent (19) Berdut 54) LEVITATION AND PROPULSION SYSTEM USING PERMANENT MAGNETS AND INTERLEAVED RON OR STEEL 76 Inventor: Elberto Berdut, Orquidea No. 98, Santa Maria, Santa Mario, Guaynabo,

NOTICE. The above identified patent application is available for licensing. Requests for information should be addressed to:

Serial No.. Filing Date July Inventor Richard Bonin NOTICE The above identified patent application is available for licensing. Requests for information should be addressed to: OFFICE OF NAVAL RESEARCH

Serial No.. Filing Date July Inventor Richard Bonin NOTICE The above identified patent application is available for licensing. Requests for information should be addressed to: OFFICE OF NAVAL RESEARCH

United States Patent (19) Smith

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

United States Patent (19) Muranishi

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

United States Patent (19) Muranishi (54) DEVICE OF PREVENTING REVERSE TRANSMISSION OF MOTION IN A GEAR TRAIN 75) Inventor: Kenichi Muranishi, Ena, Japan 73) Assignee: Ricoh Watch Co., Ltd., Nagoya, Japan

A Practical Guide to Free Energy Devices

A Practical Guide to Free Energy Devices Part PatD11: Last updated: 3rd February 2006 Author: Patrick J. Kelly Electrical power is frequently generated by spinning the shaft of a generator which has some

A Practical Guide to Free Energy Devices Part PatD11: Last updated: 3rd February 2006 Author: Patrick J. Kelly Electrical power is frequently generated by spinning the shaft of a generator which has some

2,407,010 ADAPTER HEAD FOR WELLS. Filed Aug. 8, Sheets-Sheet. Lester C. Hudson

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

(12) United States Patent (10) Patent No.: US 6,429,647 B1

USOO6429647B1 (12) United States Patent (10) Patent No.: US 6,429,647 B1 Nicholson (45) Date of Patent: Aug. 6, 2002 (54) ANGULAR POSITION SENSOR AND 5,444,369 A 8/1995 Luetzow... 324/207.2 METHOD OF MAKING

USOO6429647B1 (12) United States Patent (10) Patent No.: US 6,429,647 B1 Nicholson (45) Date of Patent: Aug. 6, 2002 (54) ANGULAR POSITION SENSOR AND 5,444,369 A 8/1995 Luetzow... 324/207.2 METHOD OF MAKING

BY 4. earea Carence A. Aroppe/ INVENTOR. Afg. 5

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

July 5, 1966 C. L. ROPPEL 3,259,343 CONTROL APPARATUS FOR WERTICAL TAKE-OFF AIRCRAFT Filed Sept. 23, l964 2. Sheets-Sheet l Afg. 5 S MX Year aa. 2 s E 2 s 1. w se s XX Se N W S. Carence A. Aroppe/ INVENTOR

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070011840A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0011840 A1 Gilli (43) Pub. Date: Jan. 18, 2007 (54) WINDSCREEN WIPER ARM (75) Inventor: Marco Gilli, Chieri

(19) United States US 20070011840A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0011840 A1 Gilli (43) Pub. Date: Jan. 18, 2007 (54) WINDSCREEN WIPER ARM (75) Inventor: Marco Gilli, Chieri

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

Six R. Seizi. United States Patent 19 ZKK, 2.S. NSS NEG. Sayo et al. 11 4,150, Apr. 24, ELECTROMAGNETIC CLUTCH NS3NS

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

(12) Patent Application Publication (10) Pub. No.: US 2005/ A1

(19) United States US 2005OO64994A1 (12) Patent Application Publication (10) Pub. No.: Matsumoto (43) Pub. Date: Mar. 24, 2005 (54) STATIONARY BIKE (52) U.S. Cl.... 482/8 (76) Inventor: Masaaki Matsumoto,

(19) United States US 2005OO64994A1 (12) Patent Application Publication (10) Pub. No.: Matsumoto (43) Pub. Date: Mar. 24, 2005 (54) STATIONARY BIKE (52) U.S. Cl.... 482/8 (76) Inventor: Masaaki Matsumoto,

(12) United States Patent

(12) United States Patent US007850483B2 (10) Patent No.: Siglock et al. (45) Date of Patent: Dec. 14, 2010 (54) POWER METER SOCKET TO CIRCUIT (56) References Cited BREAKER CONNECTION U.S. PATENT DOCUMENTS

(12) United States Patent US007850483B2 (10) Patent No.: Siglock et al. (45) Date of Patent: Dec. 14, 2010 (54) POWER METER SOCKET TO CIRCUIT (56) References Cited BREAKER CONNECTION U.S. PATENT DOCUMENTS

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19)

United States Patent (19) McKay 54 (75) 73 21 22 51 (52) 58 56 PNEUMATIC EMPTY/LOAD PROPORTIONING FOR ELECTRO PNEUMATIC BRAKE Inventor: Albert A. McKay, Stoney Creek, Canada Assignee: Westinghouse Air

United States Patent (19) McKay 54 (75) 73 21 22 51 (52) 58 56 PNEUMATIC EMPTY/LOAD PROPORTIONING FOR ELECTRO PNEUMATIC BRAKE Inventor: Albert A. McKay, Stoney Creek, Canada Assignee: Westinghouse Air

USOO582O2OOA United States Patent (19) 11 Patent Number: 5,820,200 Zubillaga et al. (45) Date of Patent: Oct. 13, 1998

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

USOO582O2OOA United States Patent (19) 11 Patent Number: Zubillaga et al. (45) Date of Patent: Oct. 13, 1998 54 RETRACTABLE MOTORCYCLE COVERING 4,171,145 10/1979 Pearson, Sr.... 296/78.1 SYSTEM 5,052,738

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

US A United States Patent (19) 11 Patent Number: 5,477,434 Reed 45) Date of Patent: Dec. 19, 1995

III IIHIIII US005477434A United States Patent (19) 11 Patent Number: Reed 45) Date of Patent: Dec. 19, 1995 54) EXTENSION BAR WITH BUILT-IN LIGHT 4,999,750 3/1991 Gammache... 362/203 USED IN CONJUCTION

III IIHIIII US005477434A United States Patent (19) 11 Patent Number: Reed 45) Date of Patent: Dec. 19, 1995 54) EXTENSION BAR WITH BUILT-IN LIGHT 4,999,750 3/1991 Gammache... 362/203 USED IN CONJUCTION

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 201200 13216A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0013216 A1 Liu et al. (43) Pub. Date: Jan. 19, 2012 (54) CORELESS PERMANENT MAGNET MOTOR (76) Inventors:

(19) United States US 201200 13216A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0013216 A1 Liu et al. (43) Pub. Date: Jan. 19, 2012 (54) CORELESS PERMANENT MAGNET MOTOR (76) Inventors:

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

United States Patent (19) Kubik

United States Patent (19) Kubik 11 Patent Number: ) Date of Patent: May, 1989 54 SELF-REGULATED HYDRAULIC CONTROL SYSTEM 76 Inventor: Philip A. Kubik, 27 Lochridge, Bloomfield Hills, Mich. 48013 21 Appl.

United States Patent (19) Kubik 11 Patent Number: ) Date of Patent: May, 1989 54 SELF-REGULATED HYDRAULIC CONTROL SYSTEM 76 Inventor: Philip A. Kubik, 27 Lochridge, Bloomfield Hills, Mich. 48013 21 Appl.

od f 11 (12) United States Patent US 7,080,599 B2 Taylor Jul. 25, 2006 (45) Date of Patent: (10) Patent No.:

US007080599B2 (12) United States Patent Taylor (10) Patent No.: (45) Date of Patent: Jul. 25, 2006 (54) RAILROAD HOPPER CAR TRANSVERSE DOOR ACTUATING MECHANISM (76) Inventor: Fred J. Taylor, 6485 Rogers

US007080599B2 (12) United States Patent Taylor (10) Patent No.: (45) Date of Patent: Jul. 25, 2006 (54) RAILROAD HOPPER CAR TRANSVERSE DOOR ACTUATING MECHANISM (76) Inventor: Fred J. Taylor, 6485 Rogers

(12) United States Patent (10) Patent No.: US 7,557,473 B2

US007557473B2 (12) United States Patent (10) Patent No.: US 7,557,473 B2 Butler (45) Date of Patent: Jul. 7, 2009 (54) ELECTROMAGNETIC RECIPROCATING 5,457,349 A * 10/1995 Gifford... 310,24 ENGINE 6,552.450

US007557473B2 (12) United States Patent (10) Patent No.: US 7,557,473 B2 Butler (45) Date of Patent: Jul. 7, 2009 (54) ELECTROMAGNETIC RECIPROCATING 5,457,349 A * 10/1995 Gifford... 310,24 ENGINE 6,552.450

(12) Patent Application Publication (10) Pub. No.: US 2011/ A1

US 2011 01 17420A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0117420 A1 Kim et al. (43) Pub. Date: May 19, 2011 (54) BUS BAR AND BATTERY MODULE INCLUDING THE SAME (52)

US 2011 01 17420A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2011/0117420 A1 Kim et al. (43) Pub. Date: May 19, 2011 (54) BUS BAR AND BATTERY MODULE INCLUDING THE SAME (52)

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1. YAMAGISH et al. (43) Pub. Date: Jun. 7, 2012

US 2012O139382A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0139382 A1 YAMAGISH et al. (43) Pub. Date: Jun. 7, 2012 (54) END PLATE, AND ROTOR FOR ROTARY Publication Classification

US 2012O139382A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0139382 A1 YAMAGISH et al. (43) Pub. Date: Jun. 7, 2012 (54) END PLATE, AND ROTOR FOR ROTARY Publication Classification

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

C. S. BRADLEY. ELECTRIC MOTOR. No. 439,102, Patented Oct. 28, n AA es'- Q wiza. -%%-4ge

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(No Model,) C. S. BRADLEY. 3. Sheets-Sheet 1, No. 439,102, Patented Oct. 28, 1890. ly W st 2. n AA 772279 es'- Q62-6- 27 22. wiza. -%%-4ge (No Mode.) - C. S., BR, ADLEY, 3. Sheets-Sheet 2. No. 439,102,

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

US 2004.00431 O2A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2004/0043102 A1 H0 et al. (43) Pub. Date: Mar. 4, 2004 (54) ALIGNMENT COLLAR FOR A NOZZLE (52) U.S. Cl.... 425/567

Sept. 20, 1971 L, A, CHESHER 3,606,112 RETRACTABLE BEVERAGE HOLDER FOR MOTOR WEHICLES. "Ne ) h \ 23. es/fs-s. Fig. 2 E3 2 (2S, Si. N.

Sept. 20, 1971 L, A, CHESHER Filed Jan. 28, 1970 3 Sheets-Sheet Hi (1. s A. 2 Wrze "Ne ) h \ 23 3f he W \, SC-3/ es/fs-s 32 33 Fig. 7 3? Y62 - - a 2 E3 2 (2S, Si Y N. aa 24 - - - - - -9 1-- //W/EW7OA Leonord

Sept. 20, 1971 L, A, CHESHER Filed Jan. 28, 1970 3 Sheets-Sheet Hi (1. s A. 2 Wrze "Ne ) h \ 23 3f he W \, SC-3/ es/fs-s 32 33 Fig. 7 3? Y62 - - a 2 E3 2 (2S, Si Y N. aa 24 - - - - - -9 1-- //W/EW7OA Leonord

(12) Patent Application Publication (10) Pub. No.: US 2004/ A1

(19) United States US 2004O104636A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0104636A1 Ortt et al. (43) Pub. Date: (54) STATOR ASSEMBLY WITH AN (52) U.S. Cl.... 310/154.08; 310/89; 310/154.12;

(19) United States US 2004O104636A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0104636A1 Ortt et al. (43) Pub. Date: (54) STATOR ASSEMBLY WITH AN (52) U.S. Cl.... 310/154.08; 310/89; 310/154.12;

(12) United States Patent

(12) United States Patent USO0955 0398B2 () Patent No.: Kraai (45) Date of Patent: Jan. 24, 2017 (54) FIFTH WHEEL LATCHING ASSEMBLY 5,7,796 * 11/1993 Thorwall et al.... 280,434 5,641,174 A 6/1997 Terry

(12) United States Patent USO0955 0398B2 () Patent No.: Kraai (45) Date of Patent: Jan. 24, 2017 (54) FIFTH WHEEL LATCHING ASSEMBLY 5,7,796 * 11/1993 Thorwall et al.... 280,434 5,641,174 A 6/1997 Terry

United States Patent (19) Shibata

United States Patent (19) Shibata 54 COOLANT CIRCULATING SYSTEM FOR MOTORCYCLE (75) Inventor: 73) Assignee: Hirotaka Shibata, Hamamatsu, Japan Yamaha Hatsudoki Kabushiki Kaisha, Iwata, Japan (21) Appl.

United States Patent (19) Shibata 54 COOLANT CIRCULATING SYSTEM FOR MOTORCYCLE (75) Inventor: 73) Assignee: Hirotaka Shibata, Hamamatsu, Japan Yamaha Hatsudoki Kabushiki Kaisha, Iwata, Japan (21) Appl.

United States Patent (19) Yamauchi et al.

United States Patent (19) Yamauchi et al. 54). GAS INSULATED SWITCHGEAR APPARATUS 75 Inventors: Takao Yamauchi; Masazumi Yamamoto; Kiyokazu Torimi; Hiroki Sanuki, all of Tokyo, Japan 73 Assignee: Mitsubishi

United States Patent (19) Yamauchi et al. 54). GAS INSULATED SWITCHGEAR APPARATUS 75 Inventors: Takao Yamauchi; Masazumi Yamamoto; Kiyokazu Torimi; Hiroki Sanuki, all of Tokyo, Japan 73 Assignee: Mitsubishi

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

s is 2. /7 1./ United States Patent (19) Nakatani et al. 5,069,266 Dec. 3, 1991 N N A-N W 2 Patent Number: (45)

United States Patent (19) akatani et al. 11 (45) Patent umber: Date of Patent: 5,069,266 Dec. 3, 1991 (54) CYLIDER BLOCKMAKIG METHOD AD DEVICE (75) Inventors: Shigeki akatani; Takahiro Idemoto, both of

United States Patent (19) akatani et al. 11 (45) Patent umber: Date of Patent: 5,069,266 Dec. 3, 1991 (54) CYLIDER BLOCKMAKIG METHOD AD DEVICE (75) Inventors: Shigeki akatani; Takahiro Idemoto, both of

(12) United States Patent (10) Patent No.: US 6,791,205 B2

USOO6791205B2 (12) United States Patent (10) Patent No.: Woodbridge (45) Date of Patent: Sep. 14, 2004 (54) RECIPROCATING GENERATOR WAVE 5,347,186 A 9/1994 Konotchick... 310/17 POWER BUOY 5,696,413 A 12/1997

USOO6791205B2 (12) United States Patent (10) Patent No.: Woodbridge (45) Date of Patent: Sep. 14, 2004 (54) RECIPROCATING GENERATOR WAVE 5,347,186 A 9/1994 Konotchick... 310/17 POWER BUOY 5,696,413 A 12/1997

April 22, 1969 R. R. MYERS 3,439,368 SWIMMING POOL CLEANER. Filled Jan. 3, //V/AA/7OA. aaaaya /7 a.a5. As / Al-Aza 47.4% r-77%---a A77 oawals

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

April 22, 1969 R. R. MYERS 3,439,368 Filled Jan. 3, SWIMMING POOL CLEANER //V/AA/7OA aaaaya /7 a.a5 As / Al-Aza 47.4% r-77%---a A77 oawals April 22, 1969 R. R. MYERS 3,439,368 SWIMMING FOOL CLEANER '-

US 7, B2. Loughrin et al. Jan. 1, (45) Date of Patent: (10) Patent No.: and/or the driven component. (12) United States Patent (54) (75)

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

United States Patent (19) Hsu

United States Patent (19) Hsu 54 STRUCTURE OF PERMANENT MAGNETIC WORK HOLDER 76 Inventor: P. J. Hsu, No. 5, Alley 1, Lane 250, Min Chuan East Road, Taipei, Taiwan 21 Appl. No.: 658,618 22 Filed: Feb. 21,

United States Patent (19) Hsu 54 STRUCTURE OF PERMANENT MAGNETIC WORK HOLDER 76 Inventor: P. J. Hsu, No. 5, Alley 1, Lane 250, Min Chuan East Road, Taipei, Taiwan 21 Appl. No.: 658,618 22 Filed: Feb. 21,

(12) United States Patent (10) Patent No.: US 7,687,950 B2. Kuckes (45) Date of Patent: Mar. 30, 2010

USOO768795OB2 (12) United States Patent (10) Patent No.: US 7,687,950 B2 Kuckes (45) Date of Patent: Mar. 30, 2010 (54) DRILLSTRING ALTERNATOR FOREIGN PATENT DOCUMENTS (75) Inventor: Arthur F. Kuckes,

USOO768795OB2 (12) United States Patent (10) Patent No.: US 7,687,950 B2 Kuckes (45) Date of Patent: Mar. 30, 2010 (54) DRILLSTRING ALTERNATOR FOREIGN PATENT DOCUMENTS (75) Inventor: Arthur F. Kuckes,

F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, , SHEETS-SHEET 2. ssna

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

(12) United States Patent

USOO7324657B2 (12) United States Patent Kobayashi et al. (10) Patent No.: (45) Date of Patent: US 7,324,657 B2 Jan. 29, 2008 (54) (75) (73) (*) (21) (22) (65) (30) Foreign Application Priority Data Mar.

USOO7324657B2 (12) United States Patent Kobayashi et al. (10) Patent No.: (45) Date of Patent: US 7,324,657 B2 Jan. 29, 2008 (54) (75) (73) (*) (21) (22) (65) (30) Foreign Application Priority Data Mar.

May 7, ,199,501. J. MacBLANE SAFETY DEVICE FOR PUNCH PRESSES. Filed May 24, Sheets-Sheet INVENTOR. utarres?eat

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2. Sheets-Sheet INVENTR utarres?eat May 7, 1940. J. MacBLANE SAFETY DEVICE FR PUNCH PRESSES Filed May 24, 1938 2 Sheets-Sheet

June 25, 1968 ROTH 3,389,738 WINDOW SHADE APPARATUS FG. 2ASE. 4b. NVENTOR LEO ROTH. was 11- a-40, 2.11u1 2y 7. A2-2.1a-42a (arte?. ATTORNEYS.

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

3.s. isit. United States Patent (19) Momotet al. 2 Šg. 11 Patent Number: 4,709,634 (45) Date of Patent: Dec. 1, Zxx (54) (75) (73)

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

(12) United States Patent

(12) United States Patent USOO698.1746B2 (10) Patent No.: US 6,981,746 B2 Chung et al. (45) Date of Patent: Jan. 3, 2006 (54) ROTATING CAR SEAT MECHANISM 4,844,543 A 7/1989 Ochiai... 297/344.26 4,925,227

(12) United States Patent USOO698.1746B2 (10) Patent No.: US 6,981,746 B2 Chung et al. (45) Date of Patent: Jan. 3, 2006 (54) ROTATING CAR SEAT MECHANISM 4,844,543 A 7/1989 Ochiai... 297/344.26 4,925,227

United States Patent (19) Hormel et al.

United States Patent (19) Hormel et al. 54 (75) (73) 21) 22) (51) 52) (58) 56) LAMP FAILURE INDICATING CIRCUIT Inventors: Ronald F. Hormel, Mt. Clemens; Frederick O. R. Miesterfeld, Troy, both of Mich.

United States Patent (19) Hormel et al. 54 (75) (73) 21) 22) (51) 52) (58) 56) LAMP FAILURE INDICATING CIRCUIT Inventors: Ronald F. Hormel, Mt. Clemens; Frederick O. R. Miesterfeld, Troy, both of Mich.

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

O E. (12) United States Patent US 7,187,087 B sa. Mar. 6, (45) Date of Patent: (10) Patent No.:

US007 187087B2 (12) United States Patent Khalizadeh (10) Patent No.: (45) Date of Patent: Mar. 6, 2007 (54) FLYWHEEL SYSTEM WITH SYNCHRONOUS RELUCTANCE AND PERMANIENT MAGNET GENERATORS (75) Inventor: Claude

US007 187087B2 (12) United States Patent Khalizadeh (10) Patent No.: (45) Date of Patent: Mar. 6, 2007 (54) FLYWHEEL SYSTEM WITH SYNCHRONOUS RELUCTANCE AND PERMANIENT MAGNET GENERATORS (75) Inventor: Claude

(12) United States Patent

(12) United States Patent A USOO6208061B1 (10) Patent No.: US 6,208,061 B1 (45) Date of Patent: Mar. 27, 2001 (54) NO-LOAD GENERATOR (75) Inventor: Jong-Sok An, Chunchen (KR) (73) Assignee: Kyung-Soo Kim,

(12) United States Patent A USOO6208061B1 (10) Patent No.: US 6,208,061 B1 (45) Date of Patent: Mar. 27, 2001 (54) NO-LOAD GENERATOR (75) Inventor: Jong-Sok An, Chunchen (KR) (73) Assignee: Kyung-Soo Kim,

ADJUSTABLE PEDAL ASSEMBLY WITH ELECTRONIC THROTTLE CONTROL RELATED APPLICATION. filed Jan. 26, 1999, U.S. Pat. No. 6,109,241.

ADJUSTABLE PEDAL ASSEMBLY WITH ELECTRONIC THROTTLE CONTROL RELATED APPLICATION [0001] This application is a continuation of application Ser. No. 09/236,975, filed Jan. 26, 1999, U.S. Pat. No. 6,109,241.

ADJUSTABLE PEDAL ASSEMBLY WITH ELECTRONIC THROTTLE CONTROL RELATED APPLICATION [0001] This application is a continuation of application Ser. No. 09/236,975, filed Jan. 26, 1999, U.S. Pat. No. 6,109,241.

(12) United States Patent (10) Patent No.: US 6,603,232 B2. Van Dine et al. (45) Date of Patent: Aug. 5, 2003

USOO6603232B2 (12) United States Patent (10) Patent No.: Van Dine et al. (45) Date of Patent: Aug. 5, 2003 (54) PERMANENT MAGNET RETAINING 4,745,319 A * 5/1988 Tomite et al.... 310/154.26 ARRANGEMENT FOR

USOO6603232B2 (12) United States Patent (10) Patent No.: Van Dine et al. (45) Date of Patent: Aug. 5, 2003 (54) PERMANENT MAGNET RETAINING 4,745,319 A * 5/1988 Tomite et al.... 310/154.26 ARRANGEMENT FOR

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

United States Statutory Invention Registration (19)

United States Statutory Invention Registration (19) P00rman 54 ELECTRO-HYDRAULIC STEERING SYSTEM FOR AN ARTICULATED VEHICLE 75 Inventor: Bryan G. Poorman, Princeton, Ill. 73 Assignee: Caterpillar Inc.,

United States Statutory Invention Registration (19) P00rman 54 ELECTRO-HYDRAULIC STEERING SYSTEM FOR AN ARTICULATED VEHICLE 75 Inventor: Bryan G. Poorman, Princeton, Ill. 73 Assignee: Caterpillar Inc.,

United States Patent (19) Miller, Sr.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

United States Patent (19)

United States Patent (19) Ogasawara et al. (54) 75 RDING LAWN MOWER Inventors: Hiroyuki Ogasawara; Nobuyuki Yamashita; Akira Minoura, all of Osaka, Japan Assignee: Kubota Corporation, Osaka, Japan Appl.

United States Patent (19) Ogasawara et al. (54) 75 RDING LAWN MOWER Inventors: Hiroyuki Ogasawara; Nobuyuki Yamashita; Akira Minoura, all of Osaka, Japan Assignee: Kubota Corporation, Osaka, Japan Appl.

United States Patent (19) Falcone

United States Patent (19) Falcone 54). DETACHABLE DOOR LOCK MEMBER FOR HINGE SIDE OF DOOR (76 Inventor: Gregory Falcone, 11 Orchard Rd., Fleetwood, Pa. 19522 (21) Appl. No.: 779,674 (22 Filed: Oct. 21,

United States Patent (19) Falcone 54). DETACHABLE DOOR LOCK MEMBER FOR HINGE SIDE OF DOOR (76 Inventor: Gregory Falcone, 11 Orchard Rd., Fleetwood, Pa. 19522 (21) Appl. No.: 779,674 (22 Filed: Oct. 21,

--- HG) F CURRENT (12) Patent Application Publication (10) Pub. No.: US 2012/ A1. f 60 HG) (19) United States MEASUREMENT

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0169284 A1 Park US 20120169284A1 (43) Pub. Date: Jul. 5, 2012 (54) (75) (73) (21) (22) (30) BATTERY CHARGING METHOD AND BATTERY

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0169284 A1 Park US 20120169284A1 (43) Pub. Date: Jul. 5, 2012 (54) (75) (73) (21) (22) (30) BATTERY CHARGING METHOD AND BATTERY

Bernick (45) Date of Patent: May 29, (54) MOVING MAGNETIC/CATHODE 4,631,106 A * 12/1986 Nakazato et al ,345.46

(12) United States Patent US007223322B2 (10) Patent No.: US 7,223,322 B2 Bernick (45) Date of Patent: May 29, 2007 (54) MOVING MAGNETIC/CATHODE 4,631,106 A * 12/1986 Nakazato et al.... 156,345.46 ARRANGEMENT

(12) United States Patent US007223322B2 (10) Patent No.: US 7,223,322 B2 Bernick (45) Date of Patent: May 29, 2007 (54) MOVING MAGNETIC/CATHODE 4,631,106 A * 12/1986 Nakazato et al.... 156,345.46 ARRANGEMENT

April 15, ,438,641. B. M., BRADEY STAIR CLIMBING WHEELCHAIR. / of 5. Filed March 3, Sheet INVENTOR. 4227%% / aezaze %2-4- ATTORNEY

April 15, 1969 Filed March 3, 1966 B. M., BRADEY STAIR CLIMBING WHEELCHAIR Sheet. / of 5 5. BY 2 4227%% / aezaze 2 %2-4- ATTORNEY April 15, 1969 Filed March 31, 1966 B, M, BRADLEY STAIR CLIMBING WHEELCHAIR

April 15, 1969 Filed March 3, 1966 B. M., BRADEY STAIR CLIMBING WHEELCHAIR Sheet. / of 5 5. BY 2 4227%% / aezaze 2 %2-4- ATTORNEY April 15, 1969 Filed March 31, 1966 B, M, BRADLEY STAIR CLIMBING WHEELCHAIR

HHRH. United States Patent (19) Lissaman et al. (11) Patent Number: 5,082,079 (45) Date of Patent: Jan. 21, 1992 (51) (54) (75) (73)

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

United States Patent (19) Lissaman et al. HHRH US00082079A (11) Patent Number:,082,079 (4) Date of Patent: Jan. 21, 1992 (4) (7) (73) 21) 22 (1) (2) (8) PASSIVELY STABLE HOVERNG SYSTEM Inventors: Assignee:

United States Patent (19) 11) 4,324,219

United States Patent (19) 11) 4,324,219 Hayashi 45) Apr. 13, 1982 54). SPARK INTENSIFIER IN GASOLINE 56) References Cited ENGINE U.S. PATENT DOCUMENTS s 703,759 7/1902 Brown... 123/169 PH 75) Inventor:

United States Patent (19) 11) 4,324,219 Hayashi 45) Apr. 13, 1982 54). SPARK INTENSIFIER IN GASOLINE 56) References Cited ENGINE U.S. PATENT DOCUMENTS s 703,759 7/1902 Brown... 123/169 PH 75) Inventor:

III If 2-1. Feb. 3, 1959 % ,871, as 55 E. 2. Filed Jan. 28, 1957 JOHN E HEWS0N J. E. HEWSON INVENTOR, ATTORNEY WALWE MANIFOLD

Feb. 3, 199 Filed Jan. 8, 197 J. E. HEWSON WALWE MANIFOLD,871,881 Sheets-Sheet l E=== D E. FEF, III If -1. FE %3- - as N & INVENTOR, JOHN E HEWS0N ATTORNEY Feb. 3, 199 J. E. HEWSON,871,881 go 4 3 a is

Feb. 3, 199 Filed Jan. 8, 197 J. E. HEWSON WALWE MANIFOLD,871,881 Sheets-Sheet l E=== D E. FEF, III If -1. FE %3- - as N & INVENTOR, JOHN E HEWS0N ATTORNEY Feb. 3, 199 J. E. HEWSON,871,881 go 4 3 a is

NSN. 2%h, WD. United States Patent (19) Vranken 4,829,401. May 9, Patent Number: 45) Date of Patent: 54) ROTATING TRANSFORMER WITH FOIL

United States Patent (19) Vranken 54) ROTATING TRANSFORMER WITH FOIL WINDINGS (75) Inventor: Roger A. Vranken, Eindhoven, Netherlands (73) Assignee: U.S. Philips Corporation, New York, N.Y. (21 Appl. No.:

United States Patent (19) Vranken 54) ROTATING TRANSFORMER WITH FOIL WINDINGS (75) Inventor: Roger A. Vranken, Eindhoven, Netherlands (73) Assignee: U.S. Philips Corporation, New York, N.Y. (21 Appl. No.:

1,702,475. Feb. 19, , F. FAHNG COIL WINDING MACHINE Filed June 27, sed. 3. Sheets-Sheet 1 INVENTOR WITNESSES: 6%s/fcA.

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

Feb. 19, 1929. - sed, F. FAHNG COIL WINDING MACHINE Filed June 27, 19 3. Sheets-Sheet 1 WITNESSES: INVENTOR 2. 6%s/fcA BY ATToRNEY s (e. 9, 1929. C. F. Air N: COIL WINDING IACHINE Fied June 27, 19 s al.)

June 3, 1969 C. F. JACOBSON 3,448,365. RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR

June 3, 1969 C. F. JACOBSON RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR Filed Aug. 15, 1966 sheet / of 2 Area/-.' 474a2%/ June 3, 1969 - C. F. JACOBSON. RECHARGEABLE

June 3, 1969 C. F. JACOBSON RECHARGEABLE BATTERY OFERATED crgarette LIGHTER AND RECHARGING AND STORAGE DEVICE THEREFOR Filed Aug. 15, 1966 sheet / of 2 Area/-.' 474a2%/ June 3, 1969 - C. F. JACOBSON. RECHARGEABLE

United States Patent (19) Latta, Jr.

United States Patent (19) Latta, Jr. 54 SCHOOL BUS STOP SIGN AND CROSSING ARM APPARATUS 75) Inventor: Joseph E. Latta, Jr., Hillsborough, N.C. 73 Assignee: Specialty Manufacturing Co., Charlotte, N.C.

United States Patent (19) Latta, Jr. 54 SCHOOL BUS STOP SIGN AND CROSSING ARM APPARATUS 75) Inventor: Joseph E. Latta, Jr., Hillsborough, N.C. 73 Assignee: Specialty Manufacturing Co., Charlotte, N.C.

(12) United States Patent (10) Patent No.: US 6,643,958 B1

USOO6643958B1 (12) United States Patent (10) Patent No.: Krejci (45) Date of Patent: Nov. 11, 2003 (54) SNOW THROWING SHOVEL DEVICE 3,435,545. A 4/1969 Anderson... 37/223 3,512,279 A 5/1970 Benson... 37/244

USOO6643958B1 (12) United States Patent (10) Patent No.: Krejci (45) Date of Patent: Nov. 11, 2003 (54) SNOW THROWING SHOVEL DEVICE 3,435,545. A 4/1969 Anderson... 37/223 3,512,279 A 5/1970 Benson... 37/244

Benson. 13 Claims, 3 Drawing Figs. (52) U.S. Cl /84, 336/212,336/ int. Cl... H01f 15/04

United States Patent (11) 3,577,109 (72) Inventors Samuel L. Foster Eagle, Wis.; Reed H. Johnston, Wellesley, Mass. 21 Appl. o. 7,4 (22 Filed Sept. 18, 1968 (45) Patented May 4, 1971 73 Assignee Allis-Chalmers

United States Patent (11) 3,577,109 (72) Inventors Samuel L. Foster Eagle, Wis.; Reed H. Johnston, Wellesley, Mass. 21 Appl. o. 7,4 (22 Filed Sept. 18, 1968 (45) Patented May 4, 1971 73 Assignee Allis-Chalmers