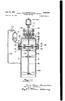

2 121,002. June 21, R. C. BAKER CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet l ATTORNEY

|

|

|

- Brendan Townsend

- 6 years ago

- Views:

Transcription

1 June 21, ,002 R. C. BAKER CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet l BY ATTORNEY

2 June 21, R. C. EBAKER 2,121,002 CEMENT RETAINER AND BRIDGE PLUG FOR WELL CASINGS 2 Sheets-Sheet 2 Filed Oct. 10, l936 N INVENTOR. BY ATTORNEYS.

3 Fferntec Jurie 2 93& 2 "2 UNITED STATES PATENT OFFICE 2, 02 CEMENTRETANER AND BRIDGE PLUG FOR. WWELL CASINGS Reuben C. Baker, Coalinga, Calif., assignor to Baker Oil Tools, Inc, untington Park, Calif., a corporation of California Application October 10, 1936, Serial No. 10, Claims. (C ) This invention relates to devices commonly centric circulating port 2 surrounded by a valve termed "cement retainers' and "bridge plugs' seat 4. which are utilized in packing off, cementing and Cooperating with this valve seat to control the other analogous operations in deep oil Wells. flow of fluid upwardly into the body from below It is the principal object of my present invenir the same is a downwardly opening back pressure is tion to provide an improved and simplified ap valve of the poppet type. This valve is fitted paratus of the character referred to which may With a valve stem 6 which extends vertically up be expeditiously run in the casing of a deep oil well bore and set at a desired point therein, and 10 efficiently employed in bridging, cementing and analogous operations. In practicing my invention, I provide a packer 4 0 body which may be detachably connected to the lower end of a string of tubing and run in the well bore. This packer body is fitted with oper ative slips for firmly anchoring it to the sur rounding casing so that it will resist dislodgement either from pressures above or pressure below it in the casing. The packer body is also fitted with an expansible packing or sealing element for sealing off the space between the exterior of the body and the casing wall. The slips or anchor ing means and the packing element are operated by fluid pressure and by manipulating the run ning in tubing at the derrick floor. The tool may be utilized in bridging the casing and in cement ing through the casing at any level above the bottom of the bore. The tool may also be used in various other operations, such as repressuring, if so desired. One form which the invention may assume is exemplified in the following description and il lustrated by way of example in the accompany ing dirawings, in which: Fig. 1 is a longitudinal sectional view through a portion of a well casing and disclosing my in proved apparatus positioned therein with the parts in the position they assume when the device is being run into the casing. Fig.2 is a view similar to Fig. 1 with the excep tion that the up-pressure slips are shown as tripped and ready for firm setting. Fig. 3 is a view similar to Fig. 2 but showing the parts in the position that they assume when the device has been completely set in the casing. Referring more particularly to the accompany ing drawings, 0 indicates a packer or what is commonly known as a cement retainer and bridge plug. This device is cylindrical in cross section and of an overall external diameter slightly less, when its parts are in unset position, than the in ternal diameter of the well casing into which it is to be run and set. The packer or cement retainer 0 includes an elongated hollow cylindrical body, the lower end of which is formed with a con ward into the body if and is reciprocably mounted in a guide formed centrally of a spider 8 formed integrally with or secured within the body. An expansion spring 9 is arranged between the guide 7 and an enlarged head 6a formed on the upper extremity of the valve stem 6. The spring 9 constantly tends to maintain the valve seated on the seat 4, thereby closing the main circulating port 2. It is obvious, however, that the valve maybe opened by fluid pressure from within the body when the same exceeds the pres Sure in the casing below the packer 0. (k For the purpose of running the body into the casing, the upper end of the body is interiorly threaded with a left-hand female thread to re ceive a left-hand male thread formed on the low er end of a tubular sub fla, which may be thread edly connected to the lower end of running in tubing 49. The purpose of the left-hand thread is to enable the sub?la and the tubing 49 to be unscrewed from the body after the tool has been tripped and set in the casing. It will be noticed that the body is hollow and cylindrical and is formed with a lower bore 28 and an upper bore 2. These two are connected by an intermediate bore 22, which is reduced in diameter with respect to the upper and lower bores 2 and. A bridging valve seat 23 is formed at the junction between the upper bore 2 and the intermediate bore 22, the purpose of this seat being hereinafter described. Slidably fitting the intermediate bore 22 is a trip sleeve 24 which has a passageway 2 formed coaxially therethrough. At its upper end the sleeve 24 is formed with a trip valve seat 26 to receive a ball trip valve 27 as shown in Fig. 2. Depending from the lower end of the sleeve 24 are Spaced legs 28 which connect the sleeve 24 to a circular trunnion 29. This trunnion 29 is connected to the head 6a by means of a shear pin. When the packer is assembled for running-in, it is desirable to hold the valve open so that 0 fluid may pass freely upwardly through the body ft. To maintain the valve in this open position, I secure the sleeve 24 to the body by a shear pin 32 which is sheared as will be described to release the sleeve and render it ineffective to hold is 0 s 2 3 4

4 O the valve open after the packer has been set in the casing. A packer sleeve, 33 formed of rubber or any other Suitable pliable material is arranged ex teriorly on the body and is anchored at its lower end to a fixed ring 34 which is bolted or otherwise secured to an annular fange 3 circum scribing the lower end of the body ff. The up per end of the packer sleeve 33 is anchored to a sliding ring 36 slidably fitting the exterior of the body. This sliding ring 36 is formed with an annular groove 36a into which is fitted a spring latch ring 37. When the packing sleeve 33 is compressed into Sealing position as shown in Fig. 3, this latch ring engages annular latching grooves 36b on the body to latch the sleeve 33 against longitudinal expansion. Referring particularly to Figs. 1 to 3, inclusive it will be seen that above the packer sleeve 3 the body is provided with a lower cone 38. This lower cone is bored so that it is capable of re ciprocation on the exterior surface of the body. The exterior of the lower cone 38 is formed with a frusto-conical face with its Smaller diam eter lowermost. Arranged about the exterior of the conical sur face of the lower cone is a set of down-pressure slips A which are segmental in form and the in terior faces of which are frusto-conical to coin cide with and be complementary to the conical face of the lower cone member 38. Obviously, any relative longitudinal movement of the cone 38 and slips. A will be accompanied by radial movement of the slips relative to the body. Referring to Fig. 1, where the parts are shown in the position which they assume when the de vice is run into the casing, it will be noticed that the slips A are arranged in their innermost po sition and that each is secured to the lower cone 38 by a shear pin 42. When the lower cone 38 is assembled on the body prior to running the tool into the casing, it is secured to the body by a shear pin 44. It will also be noticed that within its lower end the lower cone 38 is formed with an annular groove 46 which receives a spring latch ring 4. This latch ring is adapted to engage the annular latch grooves 36b formed about the exterior surface of the body to latch the lower cone 3 in posi tion on the body when the tool has been run in the casing and set as will be described. Reciprocably mounted on the body above the lower cone 38 is an upper cone member 0 which has a frusto-conical face arranged with its smaller diameter uppermost. Arranged about the conical face f of the upper cone is a set of up-pressure slips B which are likewise segmen tal and which are formed with an interior cond cal face coinciding with and complemental to the conical face of the upper cone member. The up-pressure slips B are each connected to the cone member 0 by a shear pin 3. - I desire to point out here that when the device is assembled for lowering into the well casing, the down-pressure set of slips A and the up pressure sets of slips B are so connected by the shear pins 42 and 3 to the lower and upper. Cones that they will be in contracted position, and will not interfere with the lowering of the device into the well casing. secured on the sub iia and positioned just above the upper end of the body fit is an annular flange b of a diameter sufficient so that it will be engaged by the slips B in any attempt of the latter to move longitudinally upward relative to the body (i. Referring more particularly to Fig. 1, it will be noticed that the lower cone member is formed with an upwardly extending annular cylinder 4 within which an annular piston, depending from the upper cone member 0, extends and is reciprocable. These telescoping parts of the lower and upper cones form an annular pres sure chamber 6 between them and suitable pack ing rings are provided and fitted to both the cylinder and the piston to prevent fluid leakage. This pressure chamber 6 communicates with the interior of the packer body through suitable ports 8. It is intended that when fluid pres Sure be built up within the packer body., that this pressure be exerted in the pressure cham ber 6, tending to move the cones 38 and 0 in opposite directions longitudinally of the packer body. To produce this internal pressure in the pack er body if the ball valve 27 is permitted to seat on the seat 26, of the sleeve 24, shutting off further circulation downwardly through the body f. Fluid pressure may then be built up within the body, and which pressure will build up in the pressure chamber 6 through the ports 8. This pressure will be insufficient to shear the pin 44 connecting the lower cone to the body, but is sufficient to move the upper cone 0 upwardly relative to the body and to the lower cone. This movement will be resisted by engagement of the slips B with the flange b, but the pressure will be sufficient to shear the pins 3, detaching the slips B from the upper cone 0. Obviously, con tinued upward movement of the upper cone 0 on the body and relative to the slips B will be accompanied by radial outward movement of the slips B until they tightly engage the casing as shown in Fig. 2. The pump pressure in the body is then re lieved and an upward strain is taken on the running-in tubing 49. The moment that the body commences to move upwardly, it will do so relative to the upper cone 0 due to the fact that the latter will be held stationary rela tive to the casing due to the contact of the slips B with the casing. This upward movement of the body.. will continue until the upper end of the cylinder 4 engages the annular abutment On the upper cone 0 at the junction between the conical face and the piston. Thereafter con tinued upward movement will move the upper cone 0 sufficiently upward to tightly jam the slips B into the wall of the casing, at which time further upward movement of the upper cone SD will be prevented. As the body continues to move upwardly, the strain will be sufficient to shear the pin 44, releasing the lower cone from the body. As this upward movement of the body if continues, the ring 36 at the upper end of the packing ele ment 3 will èngage the lower, ends of the seg mental slips A, moving them upwardly relative to the lower cone and shearing the pins 42. Ob viously, further upward movement of the body will move the slips into contact with the casing due to the complementary conical, faces of the lower cone and the slips, As the body continues to move upwardly, th ring 36 will remain stationary because of being blocked from further upward movement by the slips, but the lower ring 34 of the packing element will continue to move upwardly with the body. This will shorten the distance between the sliding

5 ring.36 and the fixed ring 84, and consequently a well bore, a cone member slidably mounted on compress the packer sleeve 33 into tight contact the exterior of said body and having a conical. with the casing and effect a seal between the exte face, segmental slips arranged about the exterior rior of the body and the casing. The packer of said conical member and having an interior sleeve 33 will maintain this position thereafter conical face complementary to the conical face due to the engagement of the latch ring 37 with of said member, shear means connecting said the annular grooves 36b, as illustrated in Fig. 3. slips to said cone member with the slips in a con The device is then set and ready for further tracted position, said cone member being respon operation. Pump pressure is again built up with sive to fluid pressure built up in said body by the pressure of the drilling fluid within the string of O tubing to move longitudinally of the body in a in the body to a value sufficient to shear the pin 32. This pressure is considerably greater than the first fluid pressure created to trip... the up pressure slips. When the pin 32 is sheared, the sleeve 24 will move downwardly, which downward movement will be accompanied by shearing of the pin connecting the sleeve 24 to the valve stem 6. This will release the valve stem and enable the valve to seat on the seat 4. The sleeve 24 will drop to an ineffective position within the lower chamber as illustrated in Fig. 3. If the device is to be used in cementing, cement slurry may then be pumped downwardly through the running-in tubing 49, thence longitudinally through the body f, opening the valve and 2 discharging through the port. 2. In most in stances the casing is perforated below the device So that the cement may discharge outwardly through the casing. After the cementing operation has been com pleted, the back pressure of the cement and the spring if 9 will close the back pressure valve and prevent the cement from passing upwardly through the body. The seal effected by the sleeve 33 will prevent the cement from passing upwardly around the body between it and the cas ing. Upon completion of the cementing operation, the running-in tubing 49 may be disconnected from the body l. due to the left-hand screw con nection : between the sub la and the body - f. I. may prefer to use in connection with this device a suitable circulating jar of any preferred type or design. If it is desired to use the apparatus here dis closed as a bridge plug, a ball 60 shown in dotted lines in Fig. 3 is dropped through the tubing after the device is set as previously described. This bridging ball 60 will seat on the seat 23 and prevent fluid from being pumped downwardly through the body. The back pressure valve f will prevent fluid from passing upwardly. through the body so consequently an effective bridge will be provided. All of the major parts of the device here shown are constructed preferably of cast iron or other material which can be readily drilled out so that after the device's usefulness has ended, it may be drilled up so as to leave the casing unobstructed. Although the device has been described for use in bridging a casing and for cementing operations, it is obvious that it has various other uses and that it may be put to these uses without departing from the present invention. While II. have shown the preferred form of my invention, it is to be understood that various changes may be made in its construction by those skilled in the art without departing from the spirit of the invention as defined in the appended claims. Having thus described my invention, what I claim and desire to secure by Letters Patent is 1. A device of the character described includ ing a cylindrical rigid body member adapted to communicate with and to be connected to the lower end of a string of tubing and lowered into direction causing said complementary conical faces to move said slips radially outward with re spect to the body, and means on the body pre venting said slips from moving longitudinally relative thereto in the direction of movement of said cone member. 2. A device of the character described includ ing a hollow cylindrical body adapted to be con nected to the lower end of the string of running-in tubing and lowered into a well bore, a cylindrical cone member slidably mounted on the exterior of the body and having a cone face with its smaller diameter uppermost, a plurality of segmental slips arranged about the exterior of said cone face, fragile means connecting said slips to said cone member and normally securing the slips in re tracted position, an annular abutment rigid with respect to the body and preventing upward move ment of said slips relative to the body, said cone member being responsive to fluid pressure built up in said body by the pressure of the drilling fluid within the running-in tubing to move longi tudinally upward with respect to the body and the slips and disrupt said fragile means and move said slips radially outward with respect to the body. 3. A device of the character described includ ing a hollow cylindrical body adapted to be con nected to the lower end of a string of running in tubing and lowered into a well bore, a cylin drical cone member slidably mounted on the ex terior of the body and having a cone face with 2. its Smaller diameter uppermost, a plurality of Segmental slips arranged about the exterior of 4 Said cone face, fragile means connecting said slips to said cone member and normally secur ing the slips in contracted position, an annu lar abutment rigid with respect to the body and preventing upward movement of said slips rela 0 tive to the body, said body having an interior valve seat formed therein, a valve member adapt ed to be passed downwardly through the tubing and body to seat on said seat to prevent the flow of fluid downwardly through the body and enable fluid pressure to be built up within the body, Said cone member being responsive to such fluid pressure to move upwardly relative to the body and the slips and thereby disrupt said fragile means and move said slips radially outward. 4. A device of the character described com prising a hollow cylindrical body adapted to be Secured to the lower end of a string of running in tubing and lowered into a well bore, a first cone member slidably mounted on the exterior of the b0dy and having a conical face, segmen tal slips arranged about the exterior of said coni cal face and having faces complementary to said conical face, whereby relative longitudinal move ment between said slips and said first cone men ber in one direction will result in radial outward novenent of Said slips, a second cone member having a conical face i arranged in opposed rela tion to the conical face of the first cone member, segmental slips arranged about the exterior of

6 the second conical member and having conical faces complemental to the conical face thereon, one of said cone members being, responsive to fluid pressure built up in said body to move lon gitudinally thereof and move its cooperative slips radially outward into engaging position, and means responsive to longitudinal movement of the body after operation of the first cone mem ber to move the slips associated with the sec ond cone member longitudinally relative thereto in a direction moving the same radially Outward with respect to the body.. A device of the character described com prising a hollow cylindrical body adapted to be secured to the lower end of a string of running in tubing and lowered into a well bore, a first cone member slidably mounted on the exterior of the body and having a conical face, segmental slips arranged about the exterior of said conical face and having faces complementary to Said conical face, whereby relative longitudinal movement be tween said slips and said first cone member in one direction will result in radia outward move ment of said slips, a second cone member hav ing a conical face arranged in opposed relation to the conical face of the first cone member, segmental slips arranged about the exterior of the second conical member and having conical faces complemental to the conical face thereon, one of said cone members being responsive to fluid pressure built up in said body to move lon gitudinally thereof and move its cooperative slips radially outward into engaging position, an an nular abutment on said body adapted to en gage the slips of the second cone member to move the same longitudinally with respect to the second cone after the first cone member has been operated whereby to move said slips radially outward into engaging position. 6. A device of the character described com prising a hollow cylindrical body adapted to be secured to the lower end of a string of running in tubing and lowered into a well bore, a first cone member slidably mounted on the exterior of the body and having a conical face, segmental slips arranged about the exterior of said conical face and having faces complementary to said conical face, whereby relative longitudinal move ment between said slips and said first cone mem ber in one direction will result in radia outward movement of said slips, a second cone member having a conical face arranged in opposed rela tion to the conical face of the first cone member, Segmental slips arranged about the exterior of the second conical member and having coni cal faces complemental to the conical face there on, one of said cone members being responsive to fluid pressure built up in said body to move longitudinally thereof and move its cooperative slips radially outward into engaging position, a packer sleeve surrounding said body and fixed thereto at one end, the other end being adjacent the slips associated with the second cone mem ber, said second mentioned end being adapted to engage said slips when said body is moved lon gitudinally with respect to the first cone mem ber after the same has been Operated to move said slips relative to said second cone member to cause the same to move radially outward and grip the casing, said packer sleeve being longi tudinally compressed upon continued longitudi nal movement of the body after said latter named slips have been placed in engaging position. 7. In a device of the character described, a hol low cylindrical body adapted to be connected to the lower end of a string of running-in tubing and lowered into a well casing, an upper cone member reciprocably mounted on the body and having a conical face with its smaller diameter uppermost, a set of segmental slips arranged about said upper cone member and having conical faces coinciding with the conical face thereof, means on Said body for preventing upward move ment of the slips relative thereto, a lower cone member attached to said body below said upper cone member and having a conical face opposed to that of the upper cone member, means where by fluid pressure exerted between the continu Ous ends of Said cone members will move said upper cone member upwardly relative to the body and move its associated slips radially outward into engagement with the casing, a set of seg mental slips arranged about the conical face of the lower cone member and having conical faces complementary thereto, said lower cone member being adapted to be prevented from upward movement by Said upper cone member after a predetermined amount of upward movement of the body member and to become detached from the body member upon continued upward move ment thereof, an annular abutment surrounding the body member below the lower cone member and adapted to engage the slips of the lower cone member upon continued upward movement of the body member and to move the same upwardly relative to said lower cone member into engaging position with respect to the casing. 8. In a device of the character described, a hol low cylindrical body adapted to be connected to the lower end of a string of running-in tubing and lowered into a Well casing, an upper cone member reciprocably mounted on the body and having a conical face with its smaller diameter uppermost, a Set of Segmental slips arranged about said upper cone member and having coni cal faces coinciding with the conical face there of, means on Said body for preventing upward movement of the slips relative thereto, a lower Cone member attached to said body below said upper cone member and having a conical face Opposed to that of the upper cone member, means whereby fluid pressure exerted between the con tiguous ends of said cone members will move said upper cone member upwardly relative to the body and move its associated slips radially outward into engagement with the casing, a set of segmen tal slips arranged about the conical face of the lower cone member and having conical faces complementary thereto, said lower cone member being adapted to be prevented from upward movement by said upper cone member after a predetermined amount of upward movement of the body member and to become detached from the body member upon continued upward move ment thereof, a packer sleeve surrounding the body below the lower cone member and anchored thereto at its upper end, a ring connected with the upper end of Said sleeve and slidably engag ing the body, said ring adapted to engage the slips of the lower cone member upon continued upward movement of the body member to engage said slips and move the same vertically with re spect to the lower cone member into engaging position with the casing, said continued upward movement of the body member resulting in axial compression and radial expansion of said packer sleeve. 9. A device of the character described includ ing a body adapted to be connected to the lower end of a string of tubing and lowered into a well O

7 bore, a conical member slidably mounted on the exterior of Said body for movement longitudi nally thereof, slips arranged about the exterior of Said member, complementary means on said slips and Said members whereby relative move ment therebetween in one direction will move Said slips laterally outward, said member being responsive to fluid pressure built up in said body by pressure of the drilling fluid within the string of tubing to move said member longitudinally relative to the body and slips to move the latter laterally outward, a Second cone member having a conical face arranged in opposed relation to the conical face of the first cone member, slips ar ranged about the exterior of the second conical member and having conical faces complemental to the conical face thereon, a packer sleeve Sur rounding Said body and fixed thereto at one end, the other end being adjacent the slips associated with the Second cone member, said second men tioned end being adapted to engage said slips When Said body is moved longitudinally with re Spect to the first COne member after the same has been Operated to move said slips relative to Said Second COne member to cause the same to move radially outward and grip the casing, said packer slip being longitudinally expanded upon continued longitudinal movement of the body after said latter named slips have been placed in engaging position. 10. A device of the character described includ ing a body adapted to communicate with and to be connected to the lower end of a string of tub ing and lowered into a well bore, spaced, slip means with oppositely directed serrations carried by Said body and adapted for radial movement, fluid actuated means carried by said body inter mediate Said slip means and actuable to actuate Said slip means, and means for directing fluid pressure from said body to said fluid actuated means to actuate the same. 11. A device of the character described includ ing a body adapted to communicate with and to be connected to the lower end of a string of tub ing and lowered into a well bore, slip means slid ably mounted on the exterior of said body, ta pered means carried by Said body and said slip means whereby relative movement therebetween will move Said slip means radially outward, an expansible chamber carried by said body and in communication therewith intermediate the tal pered means carried by Said body, Said expansi ble chamber being responsive to fluid pressure built up in said chamber and body to actuate Said slip means. REUBEN C. BAKER. O 1 2

?zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz -! zzzzzzzzz,zzzzzzzzz. sssss?sssssss,! PATENTED JULY 21, PNEU MATIC SUSPENSION MEANS, J. H.

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

J. H. CLARK, PNEU MATIC SUSPENSION MEANS, APPLICATION FILED JUNE 24 1907. PATENTED JULY 21, 1908. sssss?sssssss,! S?zzzzzzzzzzzzzZZZZZZZZZZZZZZZZZZZZZZZZZZ -! SN 22 222 zzzzzzzzz,zzzzzzzzz INVENTOR ZVetezrzes...

Aug. 10, ,595,232 W. S. HARLEY ELECTRIC SWITCH. HParié a. % - se. Zezezza77. Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J.,

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

Aug. 10, 1926. 1,595,232 W. S. HARLEY ELECTRIC SWITCH Filed April 13, 1922 2. Sheets-Sheet f t Fre ls HParié a % - se Sh Zezezza77 Za2z/2a22 J/622ce/ 72/ ( clo-c-3 v (J., Aug. 10, 1926. 1,595,232 W. S.

3,114,326 12/1963 Yaindi... 62/55 3,206,110 9/1965 Waibel /567 3,260,217 7/1966 Thresher /569

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

United States Patent (19) Yaindl 54 RECIPROCATING PLUNGER PUMP WITH IMPROVED LIQUID END WALVE ASSEMBLY 75 Inventor: 73) Assignee: Charles Yaindl, Harrison, N.J. Worthington Pump, Inc., Mountainside, N.J.

Mizilt 22A. United States Patent (19) 4,721,175. Jan. 26, Patent Number: 45 Date of Patent: 54 RACK AND PINION STEERING GEAR

United States Patent (19) Butler 54 RACK AND PINION STEERING GEAR ASSEMBLY (75) Inventor: Philip M. Butler, Mudgley, Great Britain 73) Assignee: TRW Cam Gears Limited, Clevedon, England 21 Appl. No.: 933,782

United States Patent (19) Butler 54 RACK AND PINION STEERING GEAR ASSEMBLY (75) Inventor: Philip M. Butler, Mudgley, Great Britain 73) Assignee: TRW Cam Gears Limited, Clevedon, England 21 Appl. No.: 933,782

2,407,010 ADAPTER HEAD FOR WELLS. Filed Aug. 8, Sheets-Sheet. Lester C. Hudson

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

Sept. 3, 1946. L. C. HUDSON 2,407,010 ADAPTER HEAD FOR WELLS Filed Aug. 8, 1945 2 Sheets-Sheet Lester C. Hudson Sept. 3, 1946. 2 407,010 L. C. HUDSON ADAPTER HEAD FOR WELLS Filled Aug. 8, 1945 2. Sheets-Sheet

45) 2,239,150 4/1941 Halliburton. 2,352,700 7/1944. Ferris. 2,715,444 8/1955 Fewel /187

United States Patent (19) Barrington et al. 11 4) Patent Number: Date of Patent: Mar. 3, 1987 4 7) 73) 21 22 1 2) (8) 6 HYDRAULCALLY SET AND RELEASED BRIDGE PLUG Inventors: Burchus Q. Barrington; Robert

United States Patent (19) Barrington et al. 11 4) Patent Number: Date of Patent: Mar. 3, 1987 4 7) 73) 21 22 1 2) (8) 6 HYDRAULCALLY SET AND RELEASED BRIDGE PLUG Inventors: Burchus Q. Barrington; Robert

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

United States Patent (19) 11) 4,444,223 Maldavs 45) Apr. 24, 1984 54) QUICK DISCONNECT COUPLING 56) References Cited U.S. PATENT DOCUMENTS 75) Inventor: Ojars Maldavs, Lincoln, Nebr. 3,039,794 6/1962 Cenzo...

Jan. 23, O. A. KEHE 2,367,682 LANDING GEAR BY-PASS WALVE. a N SS SS N NS SS M6 SS M9 O NSN y I 2 N 6. DESV at. at 2.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

Jan. 23, 1945. O. A. KEHE 2,367,682 LANDING GEAR BY-PA WALVE Filed April 9, 1943 3 heets-heet l YN N sn N N N N 2 33. a N ag M6 M9 /3 O 7 2 33 NEi NN y I 2 N 6 N3222X2 are %.. DEV at Exe mm Mm at 2 22.

2,042,301. VALVE SEAT FOR AIR BLAST WALVES Filled May 3, Sheets-Sheet. By??????r /7

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

May 26, 1936. G. FOX VALVE SEAT FOR AIR BLAST WALVES Filled May 3, 1934 2 Sheets-Sheet 11 -W + By??????r /7 May 26, 1936. G. FOX WALWE SEAT FOR AIR BLAST WALWES Filed May 3, 1934 %22&zzzzzzzzº2zzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzzz

Feb. 9, ,168,853 R. PRINCE HYDRAULIC CYLINEDER DEVICE. Filed Oct. 8, Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2.

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

Feb. 9, 1965 Filed Oct. 8, 1962 R. PRINCE HYDRAULIC CYLINEDER DEVICE 3,168,853 2 Sheets-Sheet l ~~~~ INVENTOR. 162/12e2 aga/2. BY Feb. 9, 1965 R. PRINCE 3,168,853 HYDRAULIC CYLINDER DEVICE Filed Oct. 8,

W. Hope. 15 Claims, 5 Drawing Figs. (52) U.S. Cl , 5ll int. Cl... F16k 43100, F16k 5/14

United States Patent (72 inventor Clyde H. Chronister 4 Kings Row, Rte. 14, Houston, Tex. 77040 (2) Appl. No. 823,103 (22 Filed May 8, 1969 45 Patented Jan. 26, 197i. 54) GATE WALVE 15 Claims, 5 Drawing

United States Patent (72 inventor Clyde H. Chronister 4 Kings Row, Rte. 14, Houston, Tex. 77040 (2) Appl. No. 823,103 (22 Filed May 8, 1969 45 Patented Jan. 26, 197i. 54) GATE WALVE 15 Claims, 5 Drawing

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

US 20070257638A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2007/0257638A1 Amend et al. (43) Pub. Date: Nov. 8, 2007 (54) TWIST LOCK BATTERY INTERFACE FOR (52) U.S. Cl....

& 9. Š. Aerary 4. Morazzzzzok. May 19, : 1,538,208. INVENTORS INTERNAL COMBUSTION MOTOR. atz Aazzzz c1. A1arclaezzf H. A. NORDWICK E. A.

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

May 19, 1925. :. H. A. NORDWICK E. A. INTERNAL COMBUSTION MOTOR Filed Oct, l9, 1923 2. Sheets-Sheet. & 9. Š W S A. SSS S S R Sr. SS SS INVENTORS Aerary 4. Morazzzzzok atz Aazzzz c1. A1arclaezzf. ar a ATTORNEY

22-y 2 24, 7. -l- az. Z é - Jan. 26, 1971 D. F. webster 3,557,549 TURBOCHARGER SYSTEM FOR INTERNAL COMBUSTION ENGINE. is is a ST.

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

Jan. 26, 1971 D. F. webster 3,557,549 23 9 -a- 3. Sheets-Sheet El -l- Area Arena S is is a ST BY DONALD F. WEBSTER Y az. Z 224 724.0 2é - 22-y 2 24, 7 Jan. 26, 1971 D. F. WEBSTER 3,557,549 3 Sheets-Sheet

2,799,479. July 16, 1957 A. W. KAMMERER SUBSURFACE ROTARY EXPANSIBLE DRILLING TOOLS. 2. Sheets-Sheet. Filed Nov. 7, 1955 ??? Zae ??22 INVENTOR.

July 16, 1957 Filed Nov. 7, 1955 Ø A. W. KAMMERER SUBSURFACE ROTARY EXPANSIBLE DRILLING TOOLS 2. Sheets-Sheet????? Zae 2??22 INVENTOR. July 16, 1957 Filed Now, 7, 1955 A. W. KAMMERER SUBSURFACE ROTARY

July 16, 1957 Filed Nov. 7, 1955 Ø A. W. KAMMERER SUBSURFACE ROTARY EXPANSIBLE DRILLING TOOLS 2. Sheets-Sheet????? Zae 2??22 INVENTOR. July 16, 1957 Filed Now, 7, 1955 A. W. KAMMERER SUBSURFACE ROTARY

June 9, ,136,364 W. D. MYERS HYDRAULICALLY SET WELL PACKER. illed March 30, Sheets-Sheet. 712 Zaz Z2 BY

June 9, 1964 illed March 30, 196 4. W. D. MYERS HYDRAULICALLY SET WELL PACKER 1-26-???? 2? 5 Sheets-Sheet 712 Zaz Z2 BY June 9, 1964 Filed March 30, 1961. W. D. MYERS HYDRAULICALLY SET WELL PACKER 3 136,364

June 9, 1964 illed March 30, 196 4. W. D. MYERS HYDRAULICALLY SET WELL PACKER 1-26-???? 2? 5 Sheets-Sheet 712 Zaz Z2 BY June 9, 1964 Filed March 30, 1961. W. D. MYERS HYDRAULICALLY SET WELL PACKER 3 136,364

2,376,968. May 29, F. M. JONES TWO-CYCLE GAS ENGINE. 2 Sheets-Sheet li. Filed Dec. 26, 1942 FIG, vucinto FREDERICK M. JONES.

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2 Sheets-Sheet li 7. FIG, 8??? ///?/ ( vucinto FREDERICK M. JONES ( Cltt May 29, 1945. F. M. JONES Filed Dec. 26, 1942 2. Sheets-Sheet 2 48 aa FG. 2 35 21

U. S. PATENT DOCUMENTS Crowley, TX ( US ) ( 72 ) Inventors : Jimmy L Carr, Fort Worth, TX ( US ) ; ( ) 43 / 248

MAI MOTOMONTANTUL DIN LONDON MINI US00980035B ( 2 ) United States Patent Carr et al ( 0 ) Patent No : US 9 80 035 B ( 45 ) Date of Patent : Nov 7 207 6 ( 54 ) DISPOSABLE SETTING TOOL ( 56 ) References

MAI MOTOMONTANTUL DIN LONDON MINI US00980035B ( 2 ) United States Patent Carr et al ( 0 ) Patent No : US 9 80 035 B ( 45 ) Date of Patent : Nov 7 207 6 ( 54 ) DISPOSABLE SETTING TOOL ( 56 ) References

No. 737,796. PATENTED SEPT. 1, 1903, J. A. WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS. APPLICATION FILED SEPT. 17, MODE 2 SEETS-SEET 1.

No. 737,796. PATENTED SEPT. 1, 1903, J. A. WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS. APPLICATION FILED SEPT. 17, 190. 0 MODE SEETS-SEET 1. t ; 3 - - { 6-? A, z aa - 31 vov tot l/5% -7. Zaeed.s \J 53

No. 737,796. PATENTED SEPT. 1, 1903, J. A. WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS. APPLICATION FILED SEPT. 17, 190. 0 MODE SEETS-SEET 1. t ; 3 - - { 6-? A, z aa - 31 vov tot l/5% -7. Zaeed.s \J 53

June 24, 1958 F. BUDRECK 2,839,965

June 24, 198 F. BUDRECK 2,839,96 COLLAPSIBLE REAR VIEW MIRROR STRUCTURE FOR - USE WITH A TRACTOR-TRAILER COMBINATION Filed Aug. 30, l9 3. Sheets-Sheet l - - Ss -------21 - - s-s 2-4 June 24, 198 F. BUDRECK

June 24, 198 F. BUDRECK 2,839,96 COLLAPSIBLE REAR VIEW MIRROR STRUCTURE FOR - USE WITH A TRACTOR-TRAILER COMBINATION Filed Aug. 30, l9 3. Sheets-Sheet l - - Ss -------21 - - s-s 2-4 June 24, 198 F. BUDRECK

Nov. 19, 1963 W. J. LEE 3,111,246 SHIRT FOLDING MACHINE Filed May ll, Sheets-Sheet 1 INVENTOR. by A-4,5- anzawy &Arafat

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

Nov. 19, 1963 W. J. LEE SHIRT FOLDING MACHINE Filed May ll, 1960 4 Sheets-Sheet 1 Wing A. Lee INVENTOR. by A-4,5- anzawy &Arafat Nov. 19, 1963 W. J. EE SHIRT FOLDING MACHINE Filed May 11, 1960 4. Sheets-Sheet

s /5 June 12, 1951 H. E. SPEARS ET AL 2,556,854 7 ZN NSN MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE Filed Oct 29, Saeets-Sheet 1

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE FOR HIGH-PRESSURE STIRRED REACTORS / Filed Oct 29, 1949 2 Saeets-Sheet 1 N 7 ZN Y N S s / NSN June 12, 191 H. E. SPEARS ET AL MAGNETIC COUPLING DRIVE

APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

H, V, KRBY, FUSHNG MECHANISM, APPLICATION FLED JAN, 27, 1917, 1253,982, Patented Jan, 15, 1918, 2. SHEES-SHEET, H, V, KRBY, FUSHING MECHANISM, APPLICATION FLED JAN, 27, 1917, 253,982, Patented Jan. 15,

EWSAN. United States Patent (19) 4,696,524. Cloyd. Sep. 29, ROBOT ARM COUPLING APPARATUS Inventor: Assignees:

United States Patent (19) Cloyd (54) (75) (73) 21) 22 51) (52) (58) (56) ROBOT ARM COUPLING APPARATUS Inventor: Assignees: William C. Cloyd, Lexington, Ky. Custom Tool & Mfg. Co.; Automation Development

United States Patent (19) Cloyd (54) (75) (73) 21) 22 51) (52) (58) (56) ROBOT ARM COUPLING APPARATUS Inventor: Assignees: William C. Cloyd, Lexington, Ky. Custom Tool & Mfg. Co.; Automation Development

(12) Patent Application Publication (10) Pub. No.: US 2002/ A1

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

(19) United States US 2002O00861 OA1 (12) Patent Application Publication (10) Pub. No.: US 2002/0008610 A1 PetersOn (43) Pub. Date: Jan. 24, 2002 (54) KEY FOB WITH SLIDABLE COVER (75) Inventor: John Peterson,

3.s. isit. United States Patent (19) Momotet al. 2 Šg. 11 Patent Number: 4,709,634 (45) Date of Patent: Dec. 1, Zxx (54) (75) (73)

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

United States Patent (19) Momotet al. (54) (75) (73) (1) () 51 5 (58) 56) PLATE CYLNDER REGISTER CONTROL Inventors: Stanley Momot, La Grange; William G. Hannon, Westchester, both of Ill. Assignee: Rockwell

s l N 2. S Aoaaaz A. u?acasow M-74a/oway, Alaata(7 & March 30, 1965 R. E. JACKSON 3,175,811 INVENTOR. A/Oaavaaaata

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

Filed April 23, 1963 4. Sheets-Sheet l. N N 2. s l s los & N " S S Aoaaaz A. u?acasow s M-74a/oway, Alaata(7 & A/Oaavaaaata 477aaAVay13. Filed April 23, 1963 4. Sheets-Sheet 2 Aroaaaz at 14 ca?sow M14A/o/ay,

March 23, 1965 J. J. ZAHURANEc 3,174,508 DOUBLE-END SHUT-OFF QUICK-CONNECT TUBE COUPLING. Filed Dec. 7, Z47774.

March 23, 196 J. J. ZAHURANEc DOUBLE-END SHUT-OFF QUICK-CONNECT TUBE COUPLING Filed Dec. 7, 1962 2Z47774 6 44 42 0 48. NSR 4 VO836) 38/72 ASNNW772, NXYXXWN777 2X2:3, S243As, Eiji 2. s YZ Ari C. SY re.

March 23, 196 J. J. ZAHURANEc DOUBLE-END SHUT-OFF QUICK-CONNECT TUBE COUPLING Filed Dec. 7, 1962 2Z47774 6 44 42 0 48. NSR 4 VO836) 38/72 ASNNW772, NXYXXWN777 2X2:3, S243As, Eiji 2. s YZ Ari C. SY re.

(12) Patent Application Publication (10) Pub. No.: US 2003/ A1

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

US 2003O190837A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0190837 A1 W (43) Pub. Date: Oct. 9, 2003 (54) BATTERY HOLDER HAVING MEANS FOR (52) U.S. Cl.... 439/500 SECURELY

F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, , SHEETS-SHEET 2. ssna

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

1229,398. F, L, BARBER & C. S. WAT 0 N, CAR TRUCK, APPLICATION FILED APR. 28, 9. Patented June 12, 1917. 2. SHEETS-SHEET 2. ssna it worris FEFFRS (c. soro ir G. vwasi trw«. * OM. 2 C I.5 35 UNITED STATES

809,643. June 9, le A. E. SMALL RAILWAY CAR DROP DOOR

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

June 9, 1931. A. E. SMALL RAILWAY CAR DROP DOOR 809,643 Filed April 25, 1929 3 Sheets-Sheet 1 /1 le------------ e. w June 9, 1931. A. E. SMALL Railway, CAR DROP DOOR Filed April 25, 1929 3 Sheets-Sheet

- F WEN N 42. Czz724,2 Zz-ssa 7ce. E. BY. Oct. 21, 1958 C. F. DASSANCE 2,856,797 3A 42. Filed June 1, 1953 INVENTOR.

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED GEAREO PULEY 2 Sheets-Sheet Filed June 1, 1953 2. WEN N 42 3A 42 INVENTOR. Czz724,2 Zz-ssa 7ce. E. BY - F - 4.2.2 Oct. 21, 1958 C. F. DASSANCE WARIABLE SPEED

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 3-vi-ucvtot 21, 6)) 7/4-ee-d

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

J, S, ROGERS, PADOCK, APPLICATION FILED MAY 15, 1915, 1,153,405. Patented Sept, 14, 1915, 2 SHEETS-S HEET i. 6)) 21, 7/4-ee-d 3-vi-ucvtot 1,153,405. J, S, ROGERS, PADOCK, APPLICAON FED MAY 5, 1915, Patented

Dec. 3, G. H. LELAND 1,737,595 ELECTRIC MOTOR W/a Av/2Ap. 2-2, 3 3 6AOAGAA. l. E/A/VD. 4772A/VAy

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC MOTOR. Filed Sept. 20, 1926 2 Sheets-Sheet - - - - - - 9. -- W/a Av/2Ap. 3 3 6AOAGAA. l. E/A/VD. 2-2, 4772A/VAy Dec. 3, 1929. G. H. LELAND 1,737,595 ELECTRIC

United States Patent (19) Koitabashi

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

United States Patent (19) Koitabashi 54 75 (73) 1 (51) (5) (58 56) ELECTROMAGNETIC CLUTCH WITH AN IMPROVED MAGNETC ROTATABLE MEMBER Inventor: Takatoshi Koitabashi, Annaka, Japan Assignee: Sanden Corporation,

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND TRUCK Filed Aug. 26, 1950 3. Sheets-Sheet l //WVEW7OA JAMES MOW/AWA April 3, 1956 J. MONTANA 2,740,484 MOTOR DRIVEN STAIR CLIMBING HAND

United States Patent 19

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

United States Patent 19 Weimer 54 BUSWAY INSULATION SYSTEM (75) Inventor: Charles L. Weimer, Beaver Falls, Pa. 73) Assignee: Westinghouse Electric Corporation, Pittsburgh, Pa. 22 Filed: Feb. 22, 1974 21

(12) Patent Application Publication (10) Pub. No.: US 2006/ A1

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

US 20060066075A1 (19) United States (12) Patent Application Publication (10) Pub. No.: US 2006/0066075A1 Zlotkowski (43) Pub. Date: Mar. 30, 2006 (54) TOWING TRAILER FOR TWO OR THREE Publication Classification

?9? DDLITETTIIN PATENTED JAN. 19, WITNESSES: No. 749,739, 2 SEEETS-SHEET 1. S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902.

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

No. 749,739, 0 0DE, S. LOUNT, TURBINE ENGINE. APPLICATION FILE.D.Nov. 14, 1902. PATENTED JAN. 19, 1904. 2 SEEETS-SHEET 1. DDLITETTIIN I-III-I-T-T-T-No.v-In-LI, I,II,II,III-I-T-N?9? WITNESSES: ATTORNEY

United States Patent (19) Belter

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

United States Patent (19) Belter 11) 45) Patent Number: Date of Patent: 4,746,023 May 24, 1988 (54) PUNCTURABLE OIL SEAL 75) Inventor: Jerome G. Belter, Mt. Prospect, Ill. 73) Assignee: Dana Corporation,

April 5, G, E, SWANSON 2,113,007 CYLINDER LOCK. NS: S.S.S.S.S Né EEE SS W. a. <SNSSSSSSSS/fde. is E( 4 NN. p7 NSN NNNN N&zo 76 v7 /6 2/23 / NS

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

April, 1938. G, E, SWANSON CYLINDER LOCK Filed May 17, 1937 2. Sheets-Sheet 1 SNNNN ÉSEŠEŠ V 443 SY NS: S.S.S.S.S Né EEE SS W. a.

10-sea /2 72/7e/ * 22%,962a. PATENTED OCT, l0, l905, No. 801,754.

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

No. 801,754. PATENTED OCT, l0, l905, J. A., WOGEL. FLUSHING APPARATUS FOR WATER CLOSETS APPLICATION FILED APR, l, 1905, 2. SHEETS-SHEET. 10-sea /2 72/7e/ * 22%,962a elitotivat No. 801,754, PATENTED OCT,

United States Patent (19)

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

United States Patent (19) Scegiel et al. 54 (75) (73) (21) 22 (51) (52) 58 (56) BEEHVE LIFTING DEVICE Inventors: Mark J. Scegiel, Crown Point; John R. Hicks, Larwill, both of Ind. Assignee: Stow-A-Crane

(2& 22 azimizzeta (S. Nov. 23, ,607, %, a222' 34uc to: /2a2u M/6a72/7. h/eletovics,

Nov. 23, 1926. 1,607,756 - H. NGRAM?tral JAR AND LIKE RECEPTACE Filed June 22, 1923 2 Sheets-Shee l -727.4 ^4 727.2 22' 2. 1%, a222' 251. 2 (S. eše - 22 azimizzeta. 34uc to: /2a2u M/6a72/7. h/eletovics,

Nov. 23, 1926. 1,607,756 - H. NGRAM?tral JAR AND LIKE RECEPTACE Filed June 22, 1923 2 Sheets-Shee l -727.4 ^4 727.2 22' 2. 1%, a222' 251. 2 (S. eše - 22 azimizzeta. 34uc to: /2a2u M/6a72/7. h/eletovics,

45a Eleft-16A. United States Patent (19) Suzuki et al. Na2 Š23X 32A. 11 Patent Number: 5,427,361. siz Sé 44

United States Patent (19) Suzuki et al. 54 VIBRATION ISOLATING APPARATUS 75 Inventors: Yasuhiro Suzuki; Hiroshi Kojima, both of Yokohama, Japan 73 Assignees: Nissan Motor Co., Ltd., Yokohama; Bridgestone

United States Patent (19) Suzuki et al. 54 VIBRATION ISOLATING APPARATUS 75 Inventors: Yasuhiro Suzuki; Hiroshi Kojima, both of Yokohama, Japan 73 Assignees: Nissan Motor Co., Ltd., Yokohama; Bridgestone

United States Patent 19 Nitschke

United States Patent 19 Nitschke (54) SPRING END CAP FOR CONVEYORROLLS 76 Inventor: Norman C. Nitschke, 9102 Buck Rd., Perrysburg, Ohio 43551 21 Appl. No.: 803,491 22 Filed: Jun. 6, 1977 5ll Int. Cl...

United States Patent 19 Nitschke (54) SPRING END CAP FOR CONVEYORROLLS 76 Inventor: Norman C. Nitschke, 9102 Buck Rd., Perrysburg, Ohio 43551 21 Appl. No.: 803,491 22 Filed: Jun. 6, 1977 5ll Int. Cl...

United States Patent (19) shioka et al.

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

United States Patent (19) shioka et al. 54 WASHING DEVICE FOR ROTARY FILLING MACHINE 75 Inventors: Yoshiji Ishioka, Kanazawa; Jyuro w Kawamura, Uchinada, both of Japan 73 Assignee: Shibuya Kogyo Company,

United States Patent (11) 3,552,663

United States Patent (11) 3,552,663 72 Inventor John Royals 21 E. Seminary Ave., Lutherville, Md. 21093 2 Appl. No. 781,550 (22 Filed Dec. 5, 1968 45) Patented Jan. 5, 1971 54 ICE SHAVING MACHINE 9 Claims,

United States Patent (11) 3,552,663 72 Inventor John Royals 21 E. Seminary Ave., Lutherville, Md. 21093 2 Appl. No. 781,550 (22 Filed Dec. 5, 1968 45) Patented Jan. 5, 1971 54 ICE SHAVING MACHINE 9 Claims,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

(19) United States US 20080000052A1 (12) Patent Application Publication (10) Pub. No.: US 2008/0000052 A1 Hong et al. (43) Pub. Date: Jan. 3, 2008 (54) REFRIGERATOR (75) Inventors: Dae Jin Hong, Jangseong-gun

uranayasa NNN (226er? Z /zcz-az77a 7-z Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING ZZZZZZZZA SSXSSSSSSSSSSS 50 \... "...

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

Dec. 1, 1959 A. F., HICKMAN 2,915,306 RUBBER TORSION SPRING Filed June 24, 1955 2 Sheets-Sheet l NYaNNNNNNNaa %2 uranayasa NNN IX ZZZZZZZZA \........ "......: S SSXSSSSSSSSSSS 50 12 42 INVENTOR. (226er?

March 16, ,173,402 W. D. CASSEL AUTOMATIC CATTLE SPRAYER. Filed Aug. 26, Sheets-Sheet l /WA70? WALTER D, CASSEL.

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

March 16, 1965 Filed Aug. 26, 1963 W. D. CASSEL 3. Sheets-Sheet l /WA70? WALTER D, CASSEL a 4-4 12, A7/0PAY March 16, 1965 W. D. CASSEL Filed Aug. 26, 1963 3. Sheets-Sheet 2 CN March 16, 1965 W. D. CASSEL

Dec. 6, 1966 JEAN-PERRE CAZALS ETAL 3,289,485 LEAK-TIGHT COUPLING DEVICE FOR MASTER-SLAVE MANIPULATOR ...A. ASW FIG.

Dec. 6, 1966 JEAN-PERRE CAZALS ETAL LEAK-TIGHT COUPLING DEVICE FOR MASTER-SLAVE MANIPULATOR Filed July 8, 196 3. Sheets-Sheet l...a. ASW y \ Sas s As -2 N 0 FIG. Dec. 6, 1966 JEAN-PERRE CAZALS ETAL LEAK-TIGHT

Dec. 6, 1966 JEAN-PERRE CAZALS ETAL LEAK-TIGHT COUPLING DEVICE FOR MASTER-SLAVE MANIPULATOR Filed July 8, 196 3. Sheets-Sheet l...a. ASW y \ Sas s As -2 N 0 FIG. Dec. 6, 1966 JEAN-PERRE CAZALS ETAL LEAK-TIGHT

United States Patent (19) Miller, Sr.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

United States Patent (19) Miller, Sr. 11 Patent Number: 5,056,448 (45) Date of Patent: Oct. 15, 1991 (54) (76. (21) (22) 51 (52) (58) PVC BOAT Inventor: Terry L. Miller, Sr., P.O. Box 162, Afton, Okla.

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

United States Patent (19) (11) 3,893,723 Boule (45) July 8, 1975 54 ELECTROMAGNETIC DOOR LOCK 76) Inventor: Esdras Boule, 1 160 Armand St., Drummondville, w Quebec, Canada 22 Filed: Jan. 31, 1974 (21)

United States Patent (19) Tolleson et al.

United States Patent (19) Tolleson et al. 11 Patent Number: Date of Patent: Sep. 26, 1989 54 (75) 73 21 (22) (51) (52) 58) 56 FLEXBLE BACKREST ASSEMBLY FOR A CHAIR Inventors: Thomas H. Toleson, Morristown;

United States Patent (19) Tolleson et al. 11 Patent Number: Date of Patent: Sep. 26, 1989 54 (75) 73 21 (22) (51) (52) 58) 56 FLEXBLE BACKREST ASSEMBLY FOR A CHAIR Inventors: Thomas H. Toleson, Morristown;

Jan. 14, ,421,236. Filed June 22, E, U, MOYER ATTORNEYS LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

Jan. 14, 1969 Filed June 22, E, U, MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER ATTORNEYS Jan. 14, 1969 E. U. MOYER LINKAGE FOR AN EJECTOR TYPE BUCKET, LOADER Filed June 22, 1967 Sheet a of 2. INVENTOR

June 25, 1968 ROTH 3,389,738 WINDOW SHADE APPARATUS FG. 2ASE. 4b. NVENTOR LEO ROTH. was 11- a-40, 2.11u1 2y 7. A2-2.1a-42a (arte?. ATTORNEYS.

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

June 25, 1968 RTH 3,389,738 Filed Feb. 23, l967 FG. WINDW SHADE APPARATUS 2 Sheets-Sheet 2ASE 35 WF 9 4b. BY year NVENTR LE RTH 2.11u1 2y 7 was 11- a-40, A2-2.1a-42a (arte?. ATTRNEYS. June 25, 1968 RTH

July 3, ,965,450 C. BROWN VEHICLE. Filed July 20, Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS

July 3,1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS July 3, 1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 2 mu x o H...H..n...m.,.,...+.,...

July 3,1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 1 INVENTOR CARI-ETC" BROWN BY MWWM ATDRNEYS July 3, 1934. C. BROWN VEHICLE Filed July 20, 1929 3 Sheets-Sheet 2 mu x o H...H..n...m.,.,...+.,...

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 20140299792A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0299792 A1 Yee et al. (43) Pub. Date: Oct. 9, 2014 (54) SEALING ABOUT A QUARTZ TUBE (52) U.S. Cl. CPC... F2IV31/005

(19) United States US 20140299792A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0299792 A1 Yee et al. (43) Pub. Date: Oct. 9, 2014 (54) SEALING ABOUT A QUARTZ TUBE (52) U.S. Cl. CPC... F2IV31/005

IIII. United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998

IIII USOO5775234A United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998 54) HEIGHT ADJUSTABLE OVERBED TABLE FOREIGN PATENT DOCUMENTS AND LOCKING DEVICE THEREFOR

IIII USOO5775234A United States Patent (19) 11 Patent Number: 5,775,234 Solomon et al. 45 Date of Patent: Jul. 7, 1998 54) HEIGHT ADJUSTABLE OVERBED TABLE FOREIGN PATENT DOCUMENTS AND LOCKING DEVICE THEREFOR

,62?925% HLIAI ELE ) w W/////7M //, aeoww. June 17, VI/27/702A 21, 1967 N SON S. Sheet 2 of 2 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE

June 17, 1969 Filed Dec. 21, 1967 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE 3 449 914 Sheet 2 of 2 N SON S RT,62?925% HLIAI ELE ) 77VI/27/702A w W/////7M //, aeoww C2 United States Patent Office Patented

June 17, 1969 Filed Dec. 21, 1967 W. H. BROWN WARIABLE FLOW TURBOFAN ENGINE 3 449 914 Sheet 2 of 2 N SON S RT,62?925% HLIAI ELE ) 77VI/27/702A w W/////7M //, aeoww C2 United States Patent Office Patented

(12) Patent Application Publication (10) Pub. No.: US 2017/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0102085 A1 Smith, III et al. US 201701 02085A1 (43) Pub. Date: Apr. 13, 2017 (54) (71) (72) (21) (22) (60) SUBSEA BOP CONTROL

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2017/0102085 A1 Smith, III et al. US 201701 02085A1 (43) Pub. Date: Apr. 13, 2017 (54) (71) (72) (21) (22) (60) SUBSEA BOP CONTROL

issue? - $4.4% Vils/lor (Zigsten July 9, 1957 Nils-Olof OLESTEN 2,798,743 FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED

July 9, 1957 Nils-Olof OLESTEN FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED AIRCRAFT TO GROUND MOUNTED SILENCERS Filed March 23, 1955 3 Sheets-Sheet l $4.4% Vils/lor (Zigsten issue? - : July

July 9, 1957 Nils-Olof OLESTEN FLEXIBLE COUPLING DEVICE FOR CONNECTING JET-ENGINE-POWERED AIRCRAFT TO GROUND MOUNTED SILENCERS Filed March 23, 1955 3 Sheets-Sheet l $4.4% Vils/lor (Zigsten issue? - : July

NZ 8 SS 10 INSULATED ELECTRICTERMINAL. United States Patent Iantorno et al. ' (15) 3,671,920 (45) June 20, 1972 ASSEMBLY

United States Patent Iantorno et al. (54) 72 73) 22) 21 ) 52 51 58) (56) INSULATED ELECTRICTERMINAL ASSEMBLY Inventors: James F. antorno, Mamaroneck; John Wagner, Pleasantville; Stephen J. Schu macher,

United States Patent Iantorno et al. (54) 72 73) 22) 21 ) 52 51 58) (56) INSULATED ELECTRICTERMINAL ASSEMBLY Inventors: James F. antorno, Mamaroneck; John Wagner, Pleasantville; Stephen J. Schu macher,

United States Patent (19) Savin et al.

United States Patent (19) Savin et al. (54) NUCLEAR REACTOR 76 Inventors: Nikolai I. Savin, ulitsa Zvezdinka, 3, kv. 71; Dmitry A. Khramov, ulitsa Kultury, 3, kv. 425; Vladimir J. Filippov, ulitsa Piskunova,

United States Patent (19) Savin et al. (54) NUCLEAR REACTOR 76 Inventors: Nikolai I. Savin, ulitsa Zvezdinka, 3, kv. 71; Dmitry A. Khramov, ulitsa Kultury, 3, kv. 425; Vladimir J. Filippov, ulitsa Piskunova,

(12) Patent Application Publication (10) Pub. No.: US 2010/ A1. (51) Int. Cl. of the spool. 20e /2-20s Z2 2 X XX 7

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0314564 A1 Hoeptner, III US 20100314564A1 (43) Pub. Date: Dec. 16, 2010 (54) APPARATUS WITH MOVABLE TIMING SLEEVE CONTROL OF

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2010/0314564 A1 Hoeptner, III US 20100314564A1 (43) Pub. Date: Dec. 16, 2010 (54) APPARATUS WITH MOVABLE TIMING SLEEVE CONTROL OF

UNITED STATES PATENT OFFICE

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

UNITED STATES PATENT OFFICE FRANKLIN A. ERRINGTON, OF NEW YORK, N. Y. PRO PE ER REVERS E G EAR IO 3O 35 40 45 SPECIFICATION forming part of Letters Patent No. 644,508, dated February 27, 1900. Application

(11) 4,398,742. United States Patent (19) Sanders. (45) Aug. 16, Assistant Examiner-Mitchell J. Hill

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

United States Patent (19) Sanders (54) HINGED DRAWBAR FOR BOAT TRAILER 76 Inventor: Robert W. Sanders, 72 Lynwood Dr., Brockport, N.Y. 144 (21) Appl. No.: 368,883 22 Filed: Apr., 1982 51) Int. Cl.... B60D

No.sse,*****<<<<<<<<<<<<

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

June 3, 1936. F. J. WOLFF MIXING WALWE Filed Dec. 9, N SY 1933,04,308. Sheets-Sheet l No.sse,*****

United States Patent (19) Smith

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

United States Patent (19) Smith 11 Patent Number: 45) Date of Patent: 4,546,754 Oct. 15, 1985 (54) YOKE ANCHOR FOR COMPOUND BOWS (75) Inventor: Max D. Smith, Evansville, Ind. 73 Assignee: Indian Industries,

(12) Patent Application Publication (10) Pub. No.: US 2008/ A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2008/0029246A1 Fratantonio et al. US 2008.0029246A1 (43) Pub. Date: (54) (75) (73) (21) (22) HEAT EXCHANGER BYPASS SYSTEM Inventors:

United States Patent (19) Votroubek et al.

United States Patent (19) Votroubek et al. 4) METHOD AND MEANS OF WINDING TORSION SPRING (7) Inventors: Leland C. Votroubek, Cedar Rapids; Duane H. Nelsen, Avoca, both of Iowa 73) Assignee: Iowa State

United States Patent (19) Votroubek et al. 4) METHOD AND MEANS OF WINDING TORSION SPRING (7) Inventors: Leland C. Votroubek, Cedar Rapids; Duane H. Nelsen, Avoca, both of Iowa 73) Assignee: Iowa State

US 7, B2. Loughrin et al. Jan. 1, (45) Date of Patent: (10) Patent No.: and/or the driven component. (12) United States Patent (54) (75)

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

USOO7314416B2 (12) United States Patent Loughrin et al. (10) Patent No.: (45) Date of Patent: US 7,314.416 B2 Jan. 1, 2008 (54) (75) (73) (*) (21) (22) (65) (51) (52) (58) (56) DRIVE SHAFT COUPLNG Inventors:

2,835,125 LATCHING MECHANISM. 3. Sheets-Sheet 2 NII N bel2. gy:jip 72UL. ali?i. 2%. s: 2. t. NU 2z, Z z? Azózzee/

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

May, 1958 H. F. GEORGE LATCHING MECHANISM 3. Sheets-Sheet 2 2 NII-376 2N bel2 (3 Sl Ig gy:jip 72UL 2 707 ali?i 2 2%. s: 2. t NU 2z, Z.427 272 z? Azózzee/ May, 1958 H. F. GEORGE LATCHING MECHANISM Filed

5:52, yz/ 2S o. (12) Patent Application Publication (10) Pub. No.: US 2004/ A1. (19) United States

(19) United States US 20040204282A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0204282 A1 Green et al. (43) Pub. Date: Oct. 14, 2004 (54) INTER-AXLE DIFFERENTIAL LOCK SHIFT MECHANISM (76)

(19) United States US 20040204282A1 (12) Patent Application Publication (10) Pub. No.: US 2004/0204282 A1 Green et al. (43) Pub. Date: Oct. 14, 2004 (54) INTER-AXLE DIFFERENTIAL LOCK SHIFT MECHANISM (76)

WAMI ENSI eae, EsNetII E A2. 2.Er. a ( A2 HEAE M - 15 / a7. Ells.S. 7 a M8 7 Ž22/ A. A. MEDDOCK 27 BY SWAZZZZ

Nov. 24, 1953 A. A. MEDDOCK AUTOMATIC QUICK DISCONNECT COUPLING Filed Dec. 28, 1948 m 2 Sheets-Sheet M - 15 /7 #3 2.Er. HEAE SWAZZZZ Fiil, WAMI FM if EsNetII 44 MA v 26 387 a7 a 26-47 (72.247 A2 7 a ENSI

Nov. 24, 1953 A. A. MEDDOCK AUTOMATIC QUICK DISCONNECT COUPLING Filed Dec. 28, 1948 m 2 Sheets-Sheet M - 15 /7 #3 2.Er. HEAE SWAZZZZ Fiil, WAMI FM if EsNetII 44 MA v 26 387 a7 a 26-47 (72.247 A2 7 a ENSI

(12) Patent Application Publication (10) Pub. No.: US 2007/ A1

(19) United States US 20070011840A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0011840 A1 Gilli (43) Pub. Date: Jan. 18, 2007 (54) WINDSCREEN WIPER ARM (75) Inventor: Marco Gilli, Chieri

(19) United States US 20070011840A1 (12) Patent Application Publication (10) Pub. No.: US 2007/0011840 A1 Gilli (43) Pub. Date: Jan. 18, 2007 (54) WINDSCREEN WIPER ARM (75) Inventor: Marco Gilli, Chieri

United States Patent (19)

United States Patent (19) Boyd (54) MAGNETIC ACTUATOR DEVICE 75 Inventor: Donald R. Boyd, Waukesha, Wis. 73) Assignee: Allis-Chalmers Corporation, Milwaukee, Wis. 22 Filed: May 29, 1973 21 Appl. No.: 3,024

United States Patent (19) Boyd (54) MAGNETIC ACTUATOR DEVICE 75 Inventor: Donald R. Boyd, Waukesha, Wis. 73) Assignee: Allis-Chalmers Corporation, Milwaukee, Wis. 22 Filed: May 29, 1973 21 Appl. No.: 3,024

Feb. 14, 1967 R. B. WENGER 3,304,094 CLIMBING WHEEL CHAIR A/C. Z. 5 is INVENTOR. a/caezo as a 7/gate, 57 d. 2. XO aoz. 1277aatavays.

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

Feb. 14, 1967 R. B. WENGER CLIMBING WHEEL CHAIR Filed Dec. 22, 1964 3. Sheets-Sheet A/C. Z. is INVENTOR. a/caezo as a 7/gate, BY 7 d. 2. XO-4-2. 32427 aoz 1277aatavays. Feb. 14, 1967 R. B. WENGER CLIMBING

*2.4 crewat (totif. I realizo. all estalla-ze. June 2, M. J. POSTER 1,807,752 AUTOMOBILE TIRE INDICATOR OR GAUGE Filed April 8, 1930.

June 2, 1931. M. J. PSTER 1,7,72 AUTMBILE TIRE INDICATR R GAUGE Filed April 8, 19 2 Sheets-Sheet 1 14 2SSSSSSSSs a2%%n 2 3. seases Élisé 2. 3 S 3 263 E 3aw 3 ES 3 e I realizo 2 all estalla-ze a slue Ig

June 2, 1931. M. J. PSTER 1,7,72 AUTMBILE TIRE INDICATR R GAUGE Filed April 8, 19 2 Sheets-Sheet 1 14 2SSSSSSSSs a2%%n 2 3. seases Élisé 2. 3 S 3 263 E 3aw 3 ES 3 e I realizo 2 all estalla-ze a slue Ig

/6/6 64. Oct. 14, , Vi: 2,613,753. Wa?ter C. Stueóira

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

Oct. 14, 1952 W. C. STUEBING, JR MOTORIZED DRIVE WHEEL ASSEMBLY FOR LIFT TKUCKS. OR THE LIKE Filed Sept. 26, 1946 3. Sheets-Sheet 1 NVENTOR Wa?ter C. Stueóira BY 64. /6/6 NE, Vi: Oct. 14, 1952 W. C. STUEBING,

US A United States Patent (19) 11 Patent Number: 5,477,434 Reed 45) Date of Patent: Dec. 19, 1995

III IIHIIII US005477434A United States Patent (19) 11 Patent Number: Reed 45) Date of Patent: Dec. 19, 1995 54) EXTENSION BAR WITH BUILT-IN LIGHT 4,999,750 3/1991 Gammache... 362/203 USED IN CONJUCTION

III IIHIIII US005477434A United States Patent (19) 11 Patent Number: Reed 45) Date of Patent: Dec. 19, 1995 54) EXTENSION BAR WITH BUILT-IN LIGHT 4,999,750 3/1991 Gammache... 362/203 USED IN CONJUCTION

(12) Patent Application Publication (10) Pub. No.: US 2014/ A1

(19) United States US 2014O124322A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124322 A1 Cimatti (43) Pub. Date: May 8, 2014 (54) NORMALLY CLOSED AUTOMOTIVE (52) U.S. Cl. CLUTCH WITH HYDRAULC

(19) United States US 2014O124322A1 (12) Patent Application Publication (10) Pub. No.: US 2014/0124322 A1 Cimatti (43) Pub. Date: May 8, 2014 (54) NORMALLY CLOSED AUTOMOTIVE (52) U.S. Cl. CLUTCH WITH HYDRAULC

March 17, 1964 N. E. MERRELL 3,125,164 RELEASABLE COUPLING DEVICE

March 17, 1964 N. E. MERRELL 3,12,164 Filed Dec. 4, 1962 RELEASABLE COUPLING DEVICE 3. Sheets-Sheet l NORMAN E. INVENTOR. MERRELL e.s.a. N. (A ATTORNEY March 17, 1964 N. E., MERRELL 3,12,164 RELEASABLE

March 17, 1964 N. E. MERRELL 3,12,164 Filed Dec. 4, 1962 RELEASABLE COUPLING DEVICE 3. Sheets-Sheet l NORMAN E. INVENTOR. MERRELL e.s.a. N. (A ATTORNEY March 17, 1964 N. E., MERRELL 3,12,164 RELEASABLE

Oct. 8, 1968 F. MELLON 3,404,927 BATTERY DISPENSER. Filed April 17, Sheets-Sheet. 2 CE. 2t c. el-n. e are. Iraverator, 7 e44 %-4-4, t/s.

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

Oct. 8, 1968 F. MELLON 3,4,927 BATTERY DISPENSER Filed April 17, 1967 2 Sheets-Sheet. i 3. el-n s e are 2 CE. 2t c 32 N Iran le Iraverator, Mezziorz, 7 e44 %-4-4, t/s. Oct. 8, 1968 Filed April 17, 1967

(12) Patent Application Publication (10) Pub. No.: US 2012/ A1

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

(19) United States US 201201.07098A1 (12) Patent Application Publication (10) Pub. No.: US 2012/0107098 A1 Tirone, III et al. (43) Pub. Date: May 3, 2012 (54) GASTURBINE ENGINE ROTOR TIE SHAFT (52) U.S.

(12) United States Patent

(12) United States Patent Nishiyama et al. USOO6174618B1 (10) Patent No.: (45) Date of Patent: Jan. 16, 2001 (54) BATTERY HOLDER (75) Inventors: Koichi Nishiyama; Yoshinori Tanaka; Takehito Matsubara,

(12) United States Patent Nishiyama et al. USOO6174618B1 (10) Patent No.: (45) Date of Patent: Jan. 16, 2001 (54) BATTERY HOLDER (75) Inventors: Koichi Nishiyama; Yoshinori Tanaka; Takehito Matsubara,

April 24, 1951 LE ROY S. schell, JR 2,550,500

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

April 24, 1951 LE ROY S. schell, JR LOW YOKE TRANSFORMER CORE Filed Sept. 24, l943 3. Sheets-Sheet Inventor: LeRouy S. Schell, v Jr., bu-all s 73Mass 29 His Attorneu. April 24, 1951 Filed Sept. 24, 1948

United States Patent (19) Dasa

United States Patent (19) Dasa 54 MULTIPLE CONFIGURATION MODEL AIRCRAFT 76) Inventor: Madhava Dasa, P.O. Box 461, Kula, Hi. 96790-0461 (21) Appl. No.: 103,954 22 Filed: Oct. 2, 1987 51) Int. Cl.... A63H

United States Patent (19) Dasa 54 MULTIPLE CONFIGURATION MODEL AIRCRAFT 76) Inventor: Madhava Dasa, P.O. Box 461, Kula, Hi. 96790-0461 (21) Appl. No.: 103,954 22 Filed: Oct. 2, 1987 51) Int. Cl.... A63H

June 11, ,092,988. Filed Jan. 9, 1962 DISPOSABLE LIGHTER CONSTRUCTION. 3. Sheets-Sheet F. C. MEYERS

June 11, 1963 Filed Jan. 9, 1962 F. C. MEYERS DISPOSABLE LIGHTER CONSTRUCTION 3. Sheets-Sheet June 11, 1963 F. C. MEYERS DISPOSABLE LIGHTER CONSTRUCTION Filed Jan. 9, 1962 3. Sheets-Sheet 2 BY 7????l &???el????

June 11, 1963 Filed Jan. 9, 1962 F. C. MEYERS DISPOSABLE LIGHTER CONSTRUCTION 3. Sheets-Sheet June 11, 1963 F. C. MEYERS DISPOSABLE LIGHTER CONSTRUCTION Filed Jan. 9, 1962 3. Sheets-Sheet 2 BY 7????l &???el????

United States Patent (19)

United States Patent (19) Jabagchourian et al. 54 HIGH VOLTAGE RELAY (75) Inventors: Hrair Jabagchourian, Carpenteria; Louis Lucas, Jr., Santa Barbara, both of Calif. 73) Assignee: Kilovac Corporation,

United States Patent (19) Jabagchourian et al. 54 HIGH VOLTAGE RELAY (75) Inventors: Hrair Jabagchourian, Carpenteria; Louis Lucas, Jr., Santa Barbara, both of Calif. 73) Assignee: Kilovac Corporation,

Six R. Seizi. United States Patent 19 ZKK, 2.S. NSS NEG. Sayo et al. 11 4,150, Apr. 24, ELECTROMAGNETIC CLUTCH NS3NS

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

United States Patent 19 Sayo et al. 54 ELECTROMAGNETIC CLUTCH 75 Inventors: Kosaku Sayo, Katsuta; Seijiro Tani, Naka; Atsushi Sugirauma, Hitachi, all of Japan 73) Assignee: Hitachi, Ltd., Japan 21 Appl.

No. 801,373. PATENTED 00T, 10, J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, HEETs-SHEET. Z2562/2ZZZ Aa27/2(272, inventor

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

No. 801,373. PATENTED 00T, 10, 1905. J. E. GEARHART, ROTARY ENGINE, APPLIOATION FILED AUG, 2, 1905. 28HEETs-SHEET. Witnesses -á22, séze Z2562/2ZZZ Aa27/2(272, inventor by Attorneys No. 80l.,373, PATENTED

United States Patent (19) Cannon et al.

United States Patent (19) Cannon et al. 54) (75) (73) 21) 22) (51 (52) (58) (56) NTERCHANGEABLE WHOLE-BODY AND NOSE-ONLY EXPOSURE SYSTEM Inventors: William C. Cannon; Rudolph T. Allemann, both of Richland,

United States Patent (19) Cannon et al. 54) (75) (73) 21) 22) (51 (52) (58) (56) NTERCHANGEABLE WHOLE-BODY AND NOSE-ONLY EXPOSURE SYSTEM Inventors: William C. Cannon; Rudolph T. Allemann, both of Richland,

Jan. 15, 1957 W. C. MESSICK 2,777,416 FIRE ALARM DEWECE AN35 QSS A. INVENTOR WARD C MESSECK. 6.1%a-4 2. sy/2c. a 77 o Aem at Ys

Jan. 1, 197 W. C. MESSICK FIRE ALARM DEWECE Filed Nov., 13, l93 2. Sheets-Sheet l 27 AN3 N QSS NS S. S A. INVENTOR WARD C MESSECK BY sy/2c 6.1%a-4 2 a 77 o Aem at Ys Jan. 1, 197 W. C. MESSECK FIRE ALARM

Jan. 1, 197 W. C. MESSICK FIRE ALARM DEWECE Filed Nov., 13, l93 2. Sheets-Sheet l 27 AN3 N QSS NS S. S A. INVENTOR WARD C MESSECK BY sy/2c 6.1%a-4 2 a 77 o Aem at Ys Jan. 1, 197 W. C. MESSECK FIRE ALARM

Feb. 23, F.. rayfield 1,846,656 SINGLE STAGE COMPRESSOR. Fied Nov. 15, Sheets-Sheet. l. -1. s s. AederacA /ARa%e?ad. 27 (6.

Feb. 23, 1932. F.. rayfield 1,846,656 Fied Nov. 15, 1929 3. Sheets-Sheet. l. -1. s s AederacA /ARa%e?ad 27 (6.44% as near-sell -ress Feb. 23, 1932. F. J. RAYFIELD 1846,656 Filed Nov. 15, 1929 5. Sheets-Sheet

Feb. 23, 1932. F.. rayfield 1,846,656 Fied Nov. 15, 1929 3. Sheets-Sheet. l. -1. s s AederacA /ARa%e?ad 27 (6.44% as near-sell -ress Feb. 23, 1932. F. J. RAYFIELD 1846,656 Filed Nov. 15, 1929 5. Sheets-Sheet

NES. sis. & ASN. 27, 2 to 2 E. // United States Patent (19) Kress 4,250,658. Feb. 17, ered by a conventional model piston engine.

United States Patent (19) Kress (11) 45) 4,250,658 Feb. 17, 1981 (54) 76) (21) 22) 63) (51) (52) 58) 56 DUCTED FAN FOR MODEL AIRCRAFT Inventor: Robert W. Kress, 27 Mill Rd., Lloyd Harbor, N.Y. 11746 Appl.

United States Patent (19) Kress (11) 45) 4,250,658 Feb. 17, 1981 (54) 76) (21) 22) 63) (51) (52) 58) 56 DUCTED FAN FOR MODEL AIRCRAFT Inventor: Robert W. Kress, 27 Mill Rd., Lloyd Harbor, N.Y. 11746 Appl.

May 19, 1964 AT TORNEY 3,133,451. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT. Filed Dec. 28, 196l. 3. Sheets-Sheet 1 R CHARD J.

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

May 19, 1964 Filed Dec. 28, 196l. R. J. THOMAs MULTIPLE REDUCTION GEAR UNIT 3. Sheets-Sheet 1 NVENTOR R CHARD J. TOMAS AT TORNEY May 19, 1964 Filed Dec. 28, 196 R. J. THOMAS MULTIPLE REDUCTION GEAR UNIT

USOOS239155A. United States Patent (19) 11 Patent Number: 5,239,155 Olsson (45) Date of Patent: Aug. 24, 1993

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

O USOOS2391A United States Patent (19) 11 Patent Number: 5,239,1 Olsson (45) Date of Patent: Aug. 24, 1993 (54) MULTIPURPOSE SPOTWELDING GUN replaceable electrode holders with different configura WITH

% Y 2. (12) Patent Application Publication (10) Pub. No.: US 2012/ A1. (19) United States. (43) Pub. Date: Aug. 30, Tanaka et al.

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2012/0216645 A1 Tanaka et al. US 20120216645A1 (43) Pub. Date: Aug. 30, 2012 (54) WORM WHEEL (75) Inventors: Yosuke Tanaka, Saitama